Manipulator cantilever weighing apparatus

A technology of weighing device and manipulator, applied in the direction of measuring device, weighing equipment testing/calibration, weighing, etc., can solve the problems of excessive error range, large error, weighing measurement troubles, etc., saving time, weighing The effect of the precision advantage

Active Publication Date: 2011-01-05

BEIJING C&W ELECTRONICS GRP +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of device has a large error when weighing lighter objects, and it is difficult to estimate the error range (or the error range is too large); the load cell installed in this type of device will have zero drift every year, All need annual inspection to correct the zero position and its own accuracy

Even if a pallet scale similar to that used in supermarkets is used as a weighing tool, the perfect combination of static (stable) weighing and weighing process cannot be avoided

These have caused puzzlement to the dynamic (acceleration) weighing measurement of small weight (within two kilograms), high precision (one thousandth), so it is necessary to improve the existing dynamic weighing device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

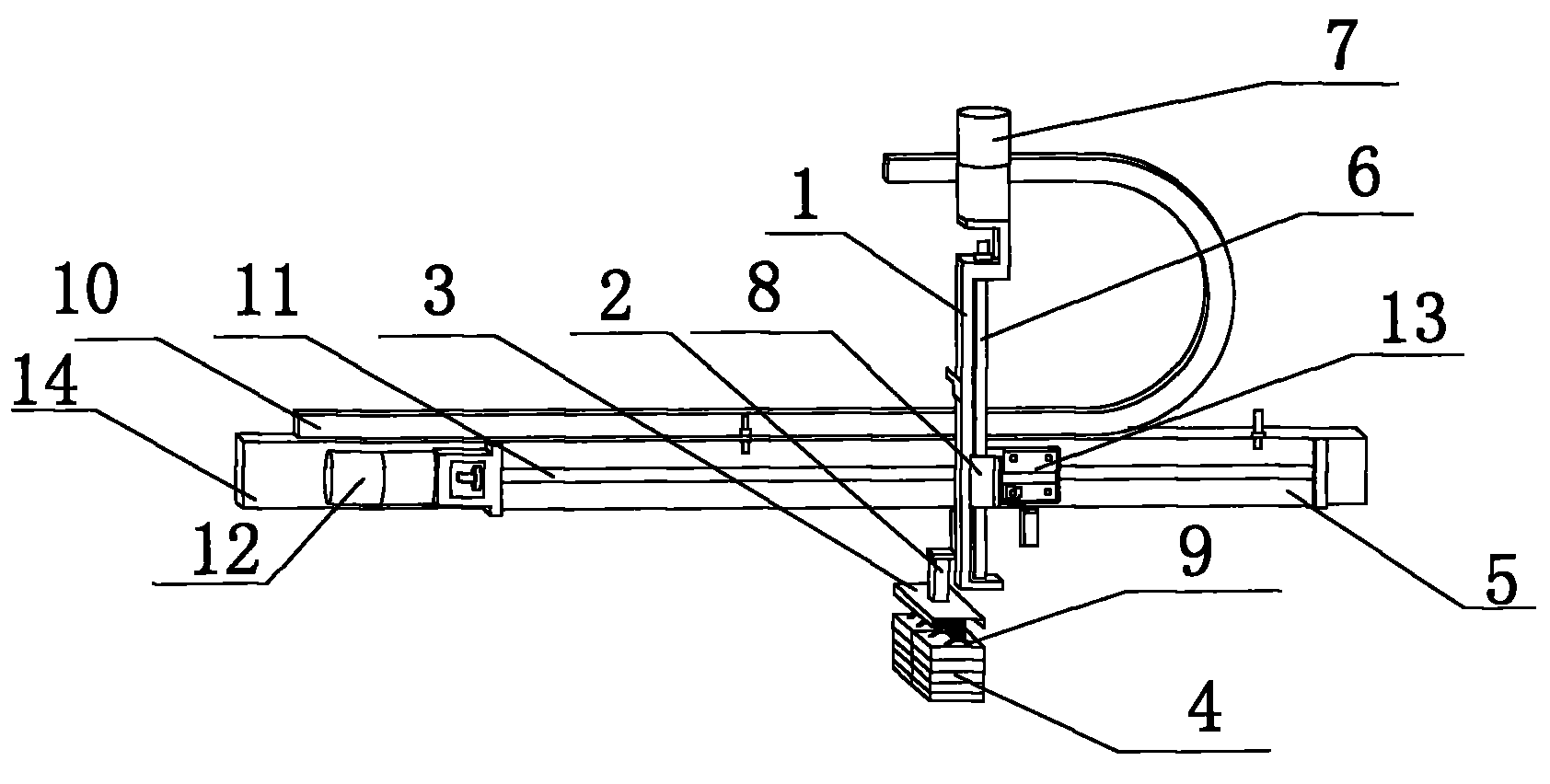

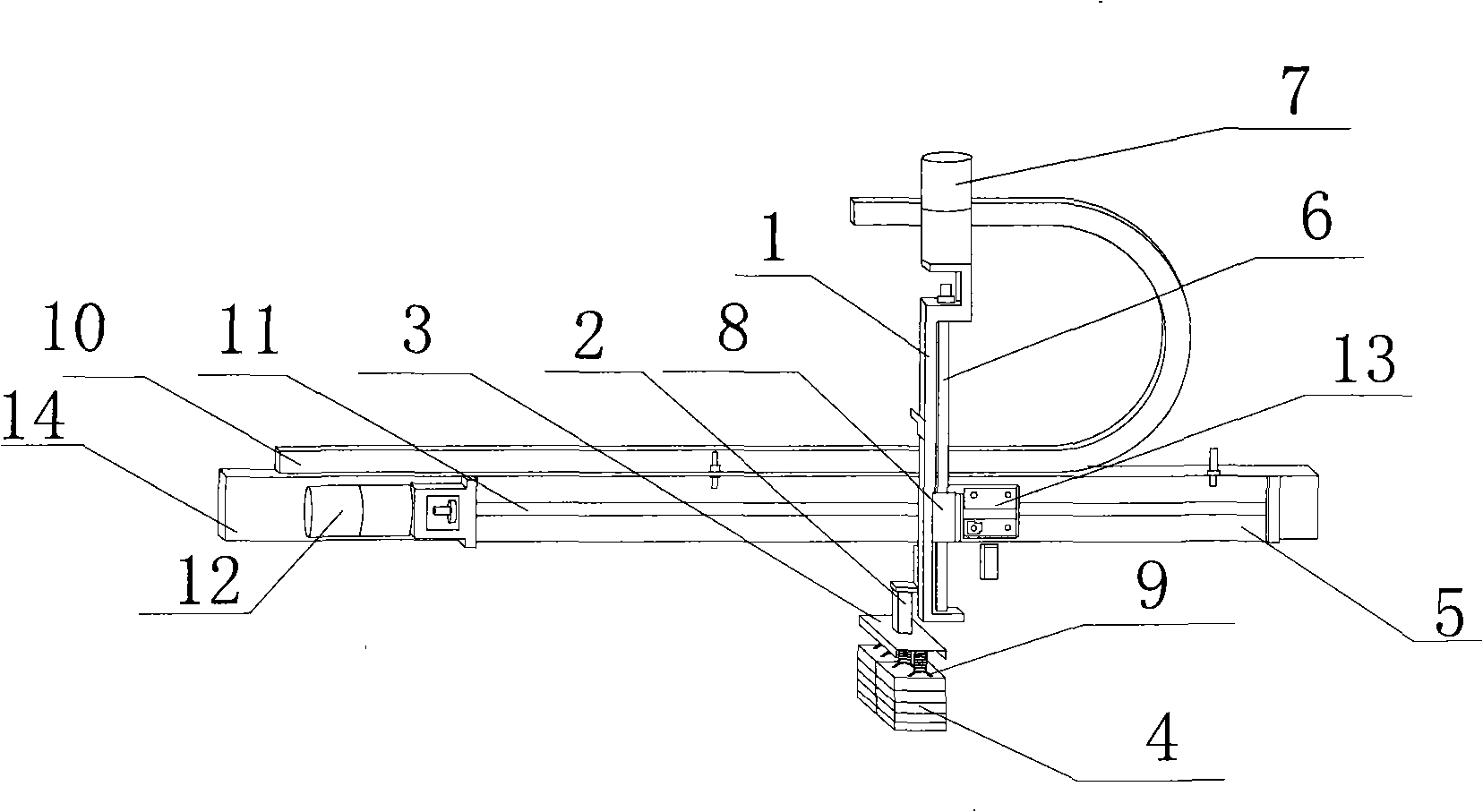

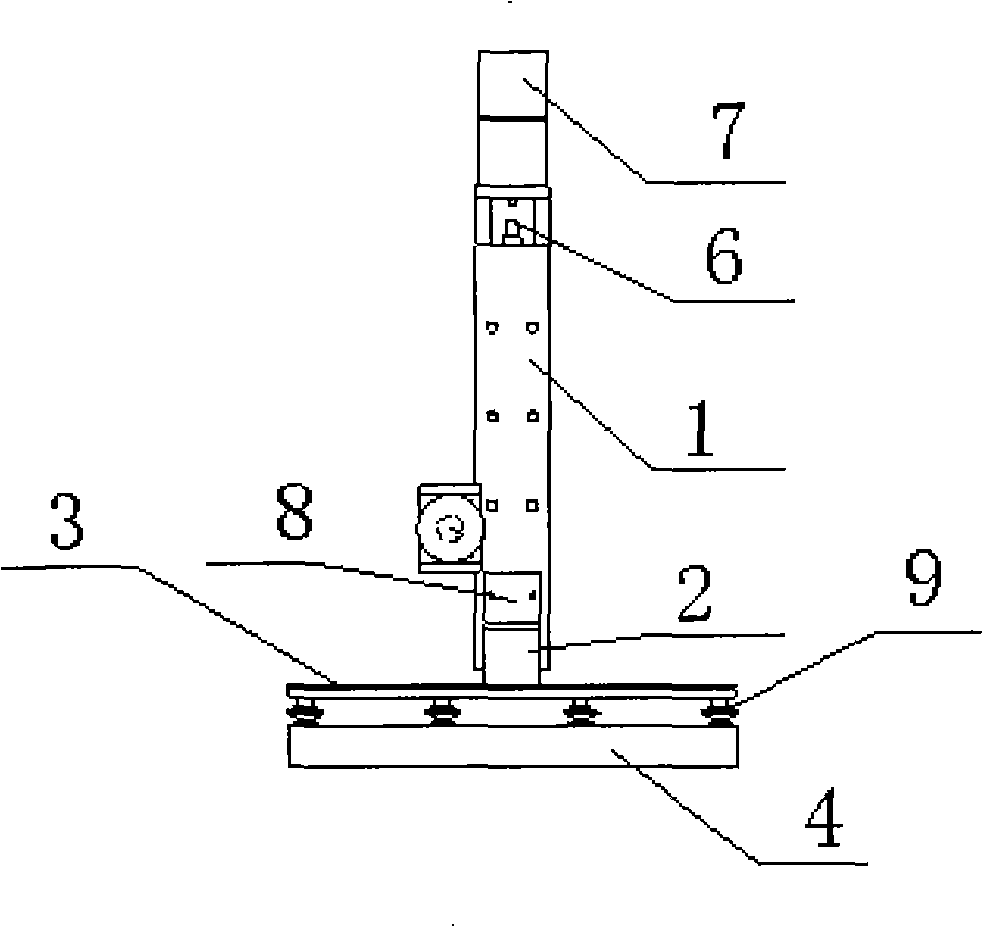

The invention relates to a dynamic weighing device, in particular to a manipulator cantilever weighing device, which comprises a vertical rectilinear guide rail, wherein a tensile pressure sensor is arranged at the lower end of the vertical rectilinear guide rail; a sucking disc support is arranged at the lower end of the tensile pressure sensor; the sucking disc support, an air pump, a reversingvalve and a pipeline form an object pickup release mechanism; the tensile pressure sensor is connected with a weighing circuit board; the vertical rectilinear guide rail is matched with a horizontal rectilinear guide rail; the vertical rectilinear guide rail can move side to side along the horizontal rectilinear guide rail; and the tensile pressure sensor, the sucking disc support and an object which is picked up or released by the sucking disc support can move up and down along the vertical rectilinear guide rail. The manipulator cantilever weighing device can combine the conveying process and the weighing process of the object, and not only can save the time, but also can quickly acquire the high-precision (one in a thousand or gram-grade weight precision) weight value of each object. Compared with the conventional belt weigh meter, the manipulator cantilever weighing device has obvious advantage in the aspect of weighing precision.

Description

Manipulator cantilever weighing device technical field The invention relates to a dynamic weighing device, in particular to a manipulator cantilever weighing device. Background technique At present, for the dynamic weighing of objects being transported or transported, the method of conveyor belt and floor scale is mainly used. This kind of device has a large error when weighing lighter objects, and it is difficult to estimate the error range (or the error range is too large); the load cell installed in this type of device will have zero drift every year, All need annual inspection to correct the zero position and its own accuracy. Even if a pallet scale similar to that used in supermarkets is used as a weighing tool, the perfect combination of static (stable) weighing and weighing process cannot be avoided. These have all caused puzzlement to the dynamic (acceleration) weighing measurement of small weight (within two kilograms), high precision (1 / 1000), so it is necessar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01G19/14G01G19/18G01G23/01

Inventor 白旭韩亚峰罗志强韩振江

Owner BEIJING C&W ELECTRONICS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com