Material dynamic double-pressing and shearing experimental device based on Hopkinson rod

An experimental device and dynamic technology, applied in the direction of using stable shear force to test the strength of materials, measuring devices, analyzing materials, etc. problem, to achieve the effect of simple operation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

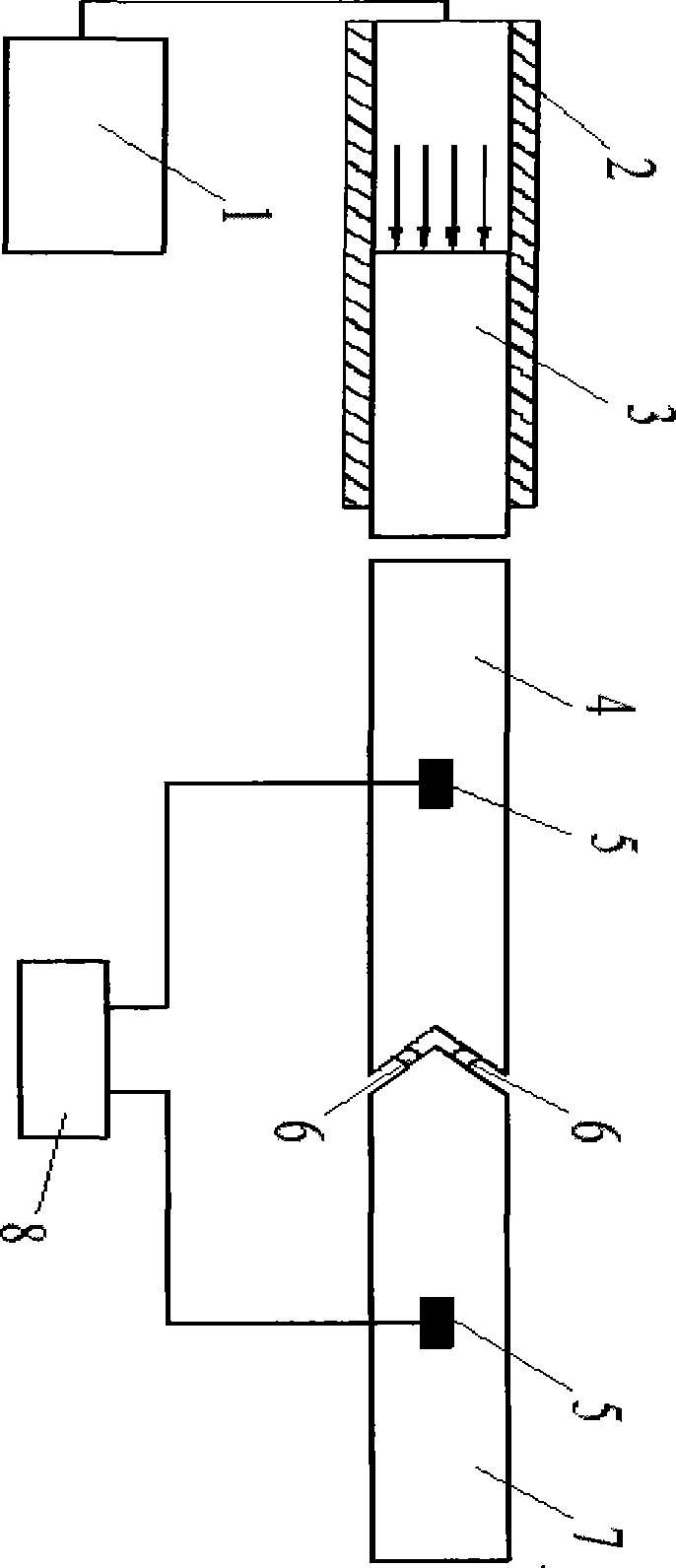

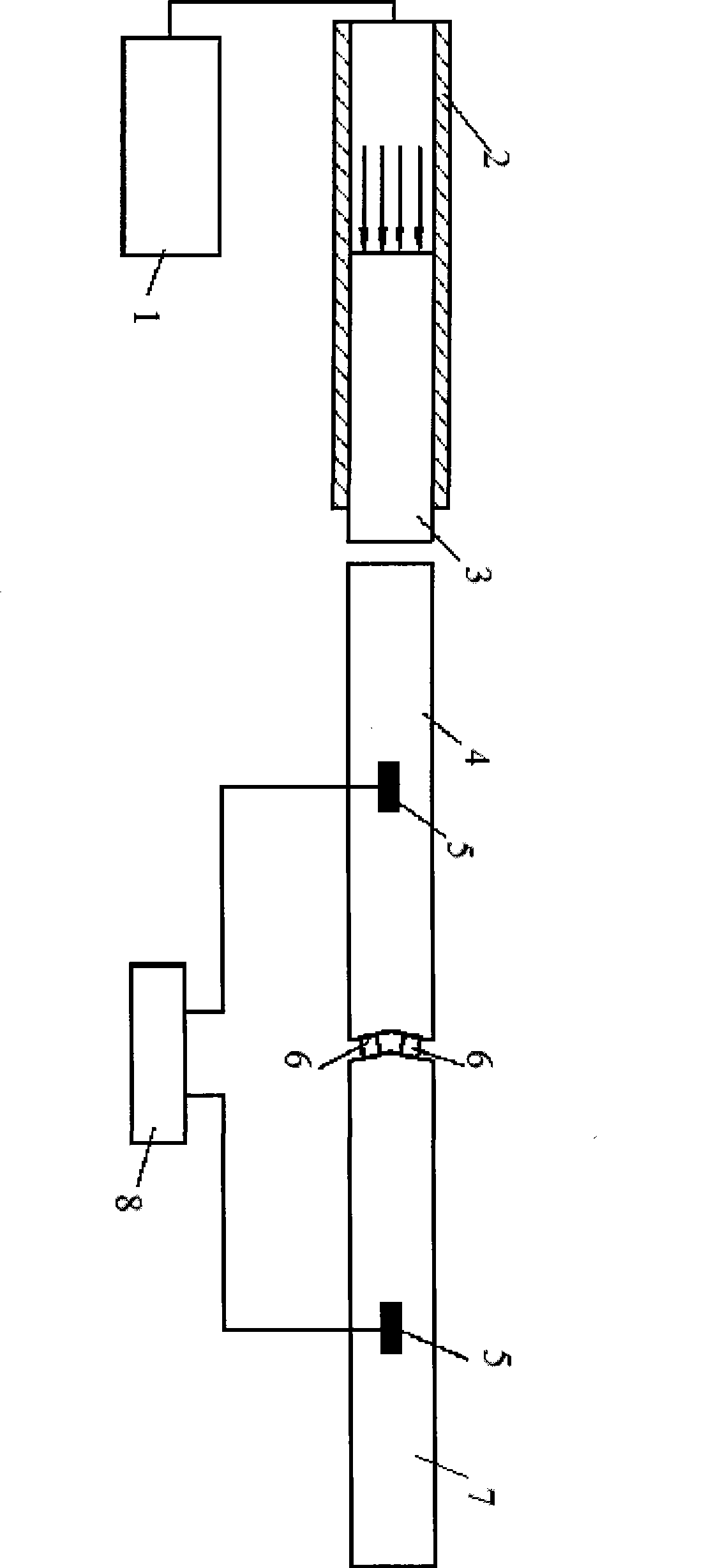

[0021] Such as figure 1 As shown: this embodiment includes a striking rod 3 , an incident rod 4 , a transmission rod 7 , two identical samples 6 , a striking rod launching mechanism 2 and a high-pressure air source 1 . In this embodiment, the end of the incident rod 4 adjacent to the transmission rod 7 is processed into a V-shaped groove, and the end of the matching transmission rod 7 is a wedge-shaped head, and the V-shaped groove of the incident rod 4 and the transmission rod 7. The included angle between the inclined plane of the wedge-shaped head and the axis of the bar is 60°. One end of the incident rod 4 with a V-shaped groove and one end of the wedge-shaped head of the transmission rod 7 are installed coaxially opposite each other, and the two samples 6 are sandwiched between the two slopes. The other end of the incident rod is provided with a striking rod 3, a striking rod launching mechanism 2 and a high-pressure air source 1. In addition, there is a data acquisiti...

Embodiment 2

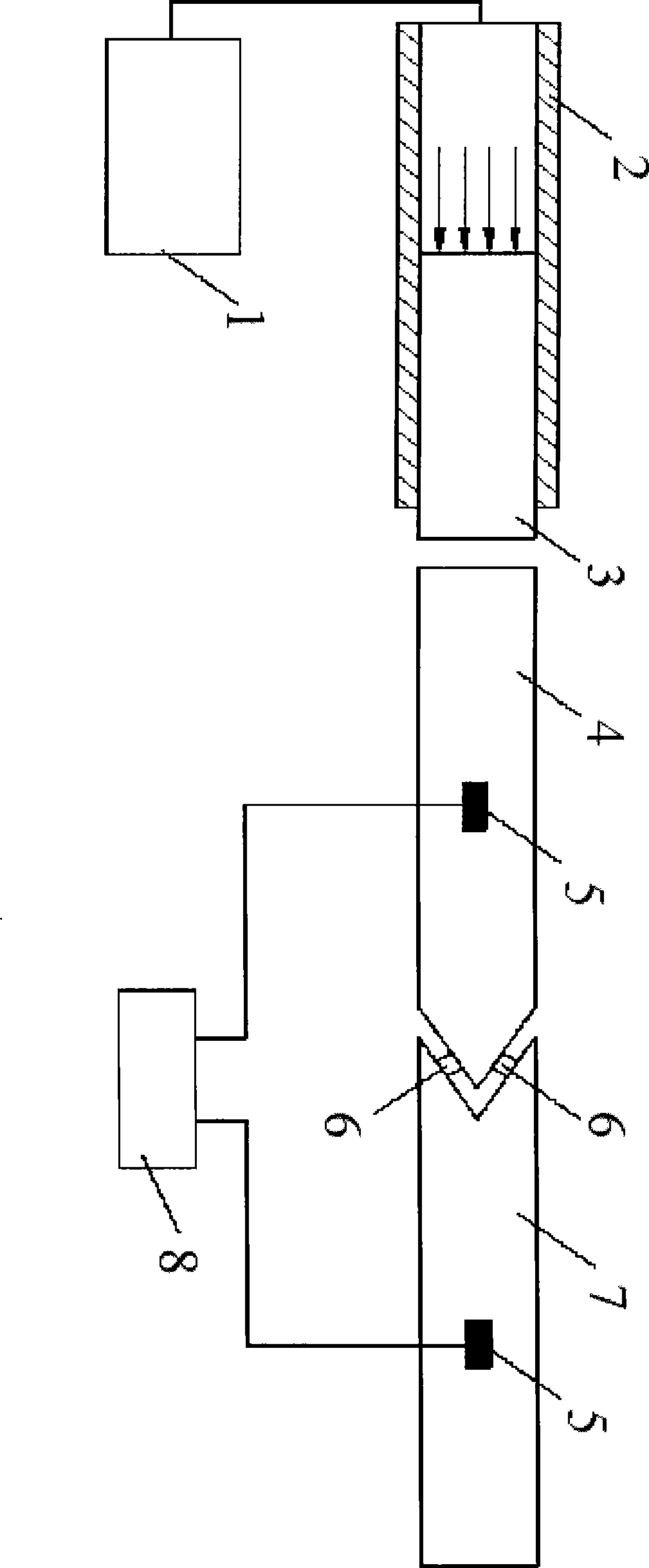

[0030] Such as figure 2 As shown: this embodiment includes a striking rod 3 , an incident rod 4 , a transmission rod 7 , two identical samples 6 , a striking rod launching mechanism 2 and a high-pressure air source 1 . In this embodiment, the difference from Embodiment 1 is that the end of the incident rod 4 in contact with the sample is processed into a wedge-shaped head, and the end of the transmission rod 7 in contact with the sample is processed into a V-shaped groove. The included angle between the slope of the wedge-shaped head and the V-shaped groove of the transmission rod 7 and the axis of the rod is 30°. One end of the wedge-shaped head of the incident rod 4 and one end of the V-shaped groove of the transmission rod 7 are installed coaxially opposite each other, and the two samples 6 are respectively sandwiched between the two inclined surfaces. The other end of the incident rod is provided with a striking rod 3, a striking rod launching mechanism 2 and a high-pres...

Embodiment 3

[0039] Such as figure 1 As shown: this embodiment includes a striking rod 3 , an incident rod 4 , a transmission rod 7 , two identical samples 6 , a striking rod launching mechanism 2 and a high-pressure air source 1 . In this embodiment, the end of the incident rod 4 adjacent to the transmission rod 7 is processed into a V-shaped groove, and the end of the matched transmission rod 7 is a wedge-shaped head, and the V-shaped groove of the incident rod 4 and the transmission rod 7. The included angle between the inclined plane of the wedge-shaped head and the axis of the rod is 80°. One end of the incident rod 4 with a V-shaped groove and one end of the wedge-shaped head of the transmission rod 7 are installed coaxially opposite each other, and the two samples 6 are sandwiched between the two slopes. The other end of the incident rod is provided with a striking rod 3, a striking rod launching mechanism 2 and a high-pressure air source 1. In addition, there is a data acquisitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com