Atomizing aerosol closed spacing igniting tester

A technology of ignition test and closed space, which is applied in the direction of analysis using chemical indicators, can solve the problems of not meeting the verification requirements, low measurement accuracy, low measurement efficiency, etc., and achieve high degree of measurement automation, high measurement accuracy, and safety good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

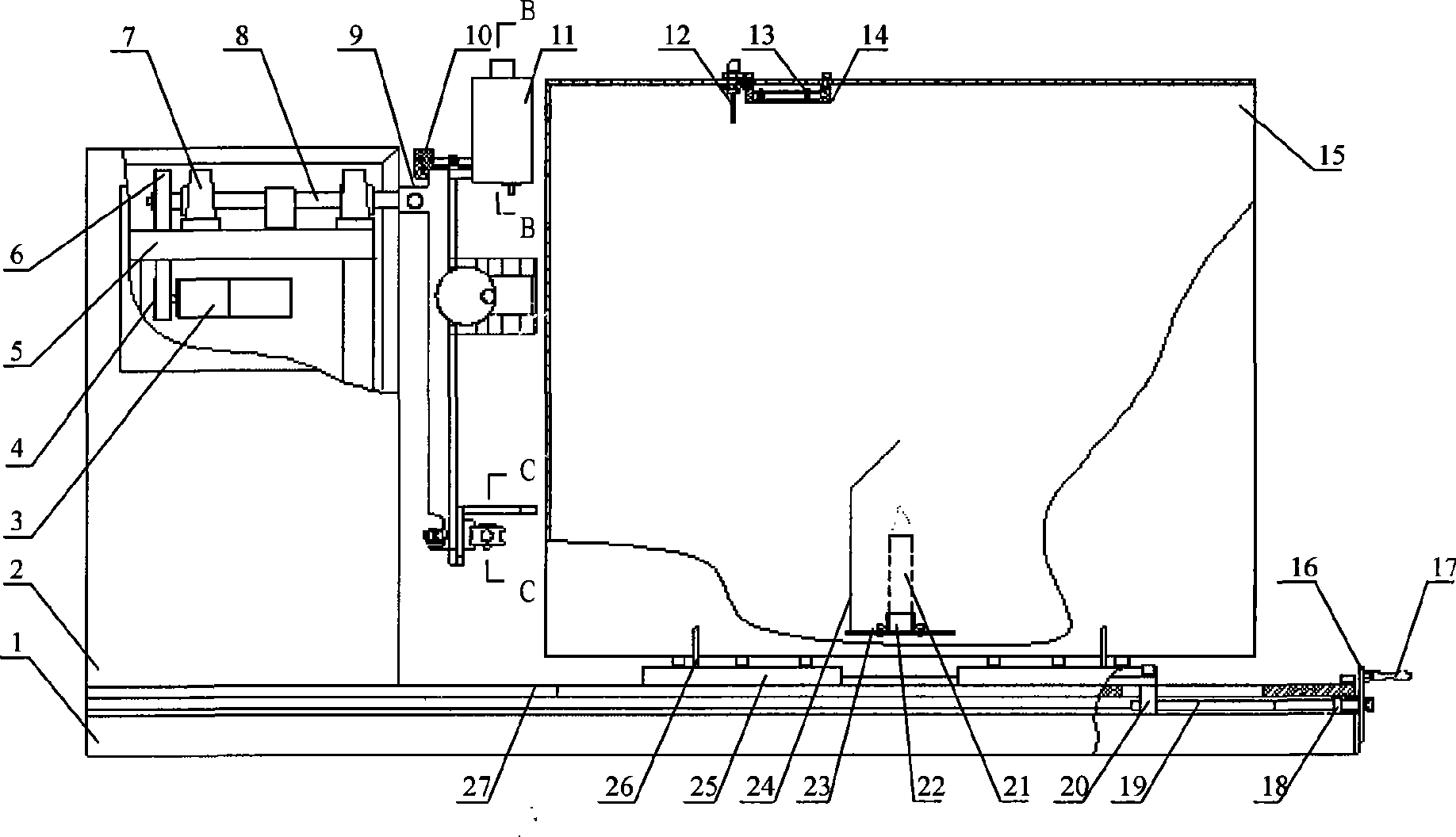

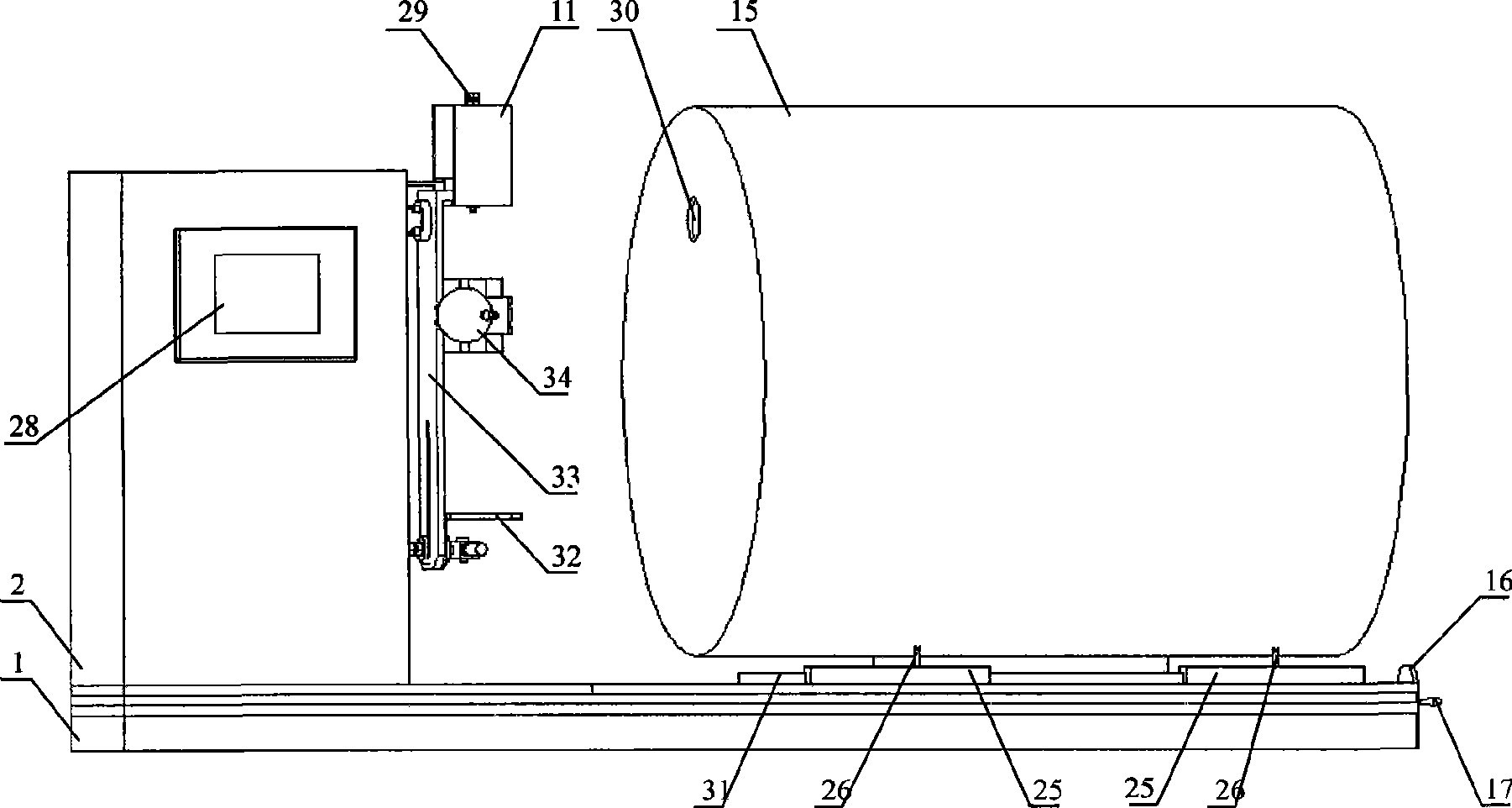

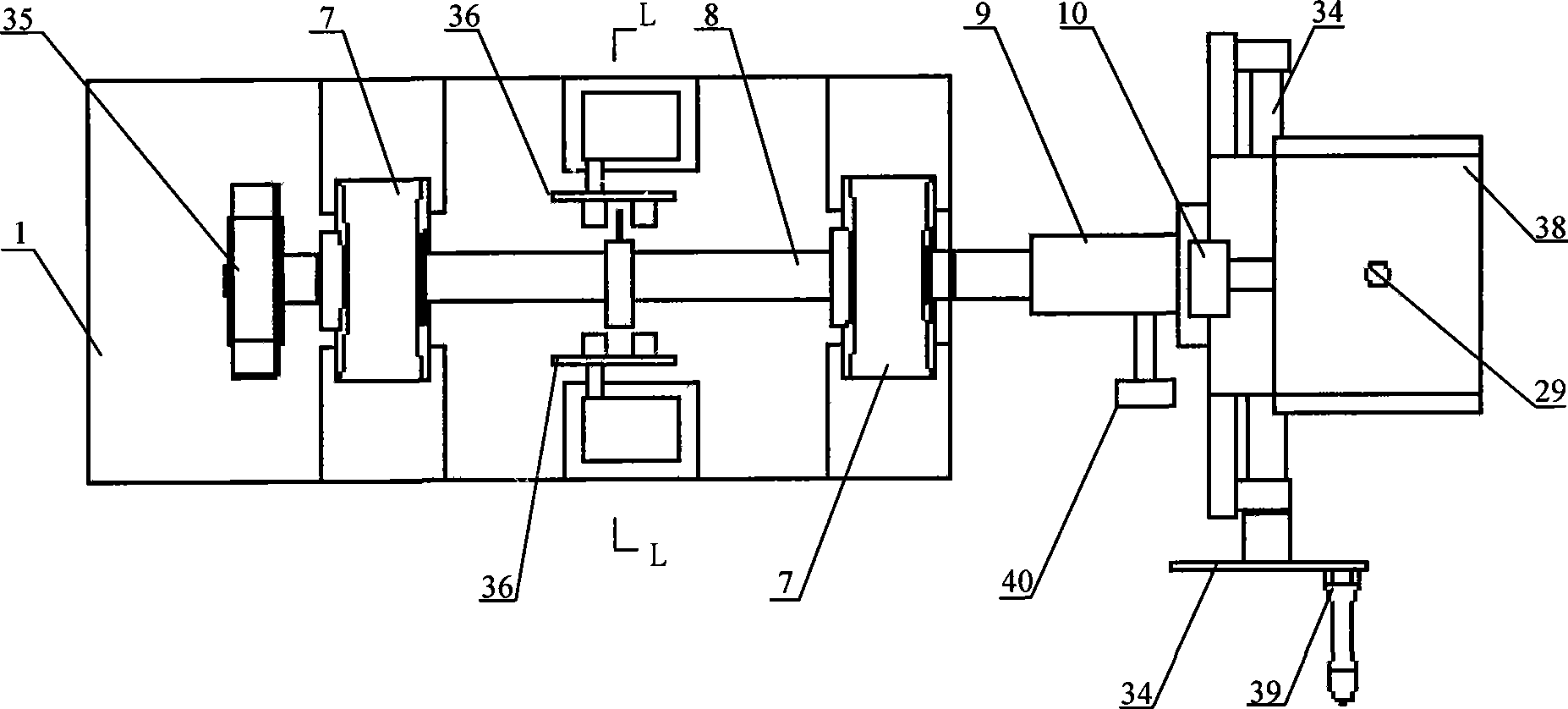

[0042] Before the start of the test, according to the requirements of GB / T 21631-2008 for sampling and sample processing, the spray aerosol closed space ignition tester is turned on, and the product name, net capacity, initial loading level, etc. are manually input on the host computer, and the temperature and humidity sensor SHT11 The temperature and humidity of the environment are collected and transmitted to the host computer. Light the candle 21, and the right end is sealed with a 0.01 to 0.02 mm thick plastic film. Place a full gas tank on the base 32, turn the third handle 44 counterclockwise, adjust the height of the base 32, make the nozzle and the round hole 30 on the cylindrical experimental container 15 equal height, and turn the third handle 44 clockwise , Fixed base 32 height. Adjust the adjusting screw mandrel 10 in the aerosol automatic spraying mechanism so that the pressure head 51 is aimed at the nozzle. Adjust the first handle 17 so that a circular hole 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com