Combined bed-knife of straw crusher

A crusher and bedknife technology, applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve problems such as affecting the shearing effect, jamming between cutterheads, reducing shearing uniformity, etc., to achieve smooth and smooth crushing process. The effect of small shock vibration and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

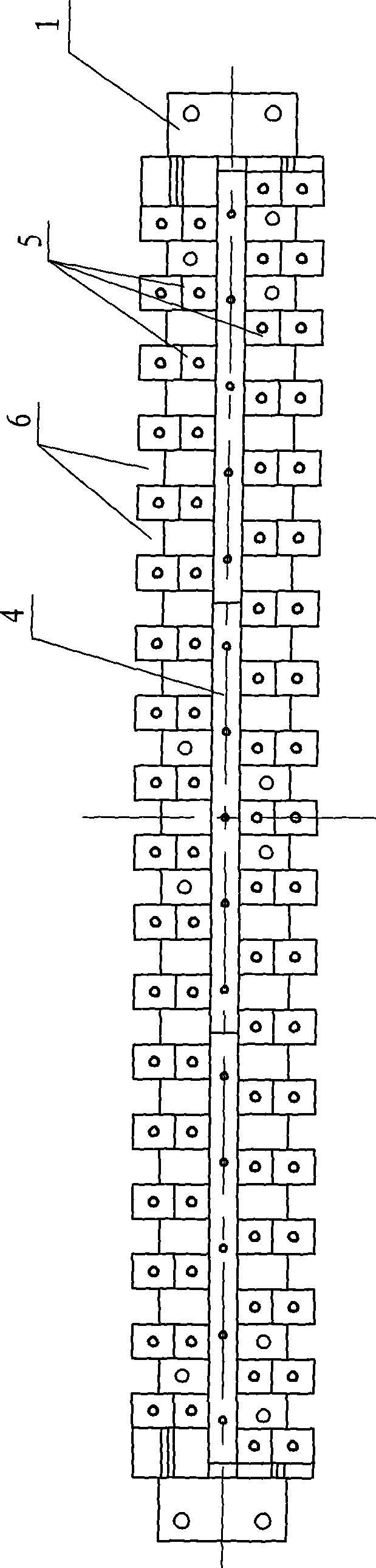

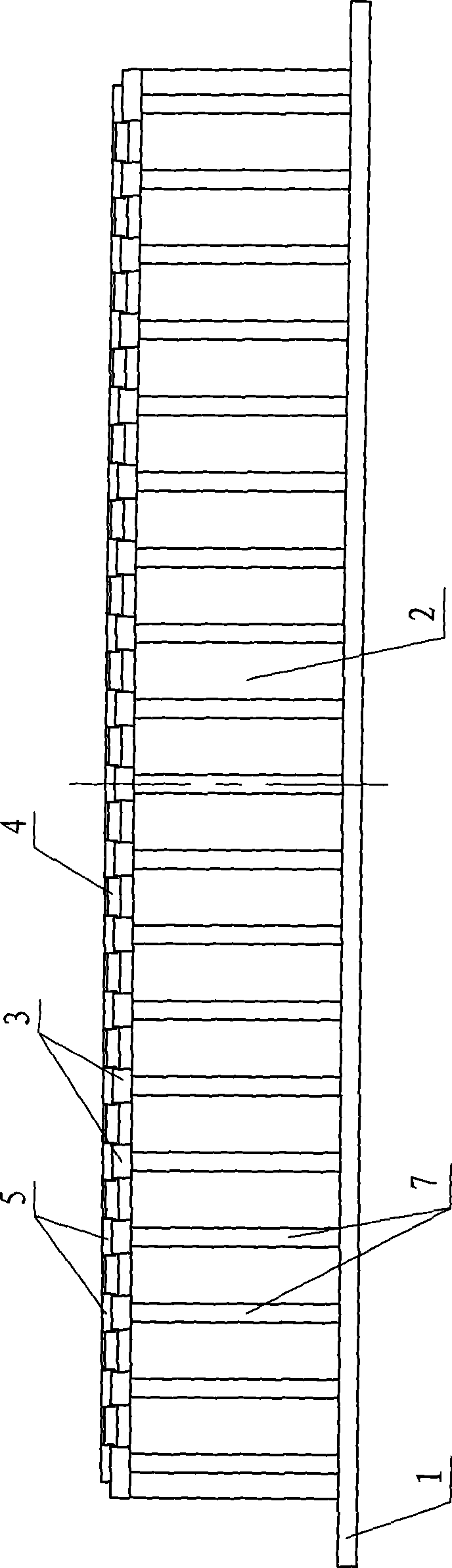

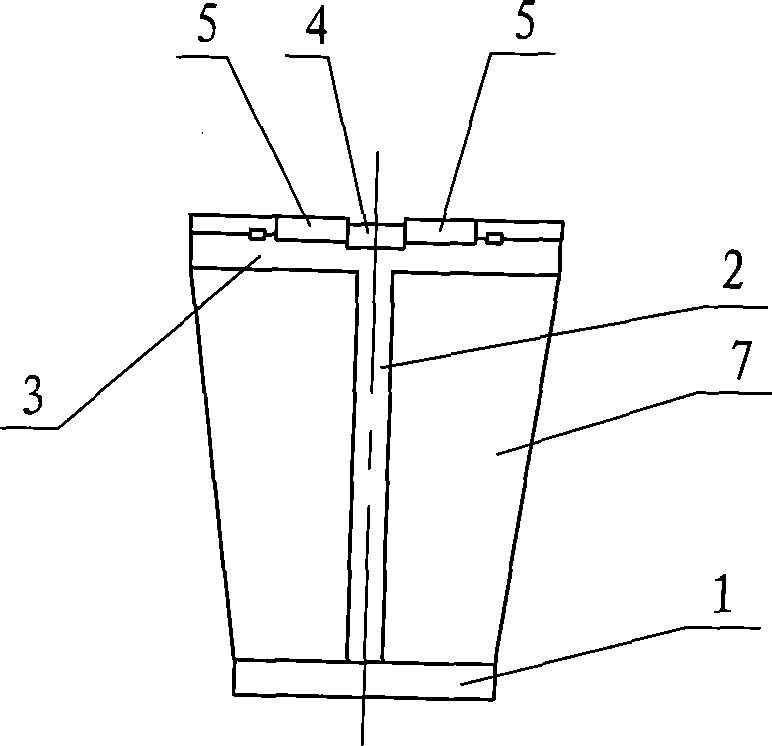

[0013] Such as Figure 1 ~ Figure 3 As shown, the combined bottom knife has a bottom knife holder, the bottom knife holder includes a horizontal bottom plate 1 and a vertical vertical plate 2, horizontal upper support plates 3 are arranged longitudinally on both sides of the top of the vertical plate; A longitudinal middle bedknife 4 is installed horizontally on the top, and a horizontal side bedknife 5 is installed horizontally on each upper pallet. The end of each side bedknife is close to the side of the middle bedknife, so that each The edges of the two adjacent side bottom knives 5 and the side edges of the middle bottom knives 4 form a U-shaped knife edge groove 6 into which the cutter disk 9 on the knife roll 8 can enter. A vertical rib 7 connecting the bottom plate, the vertical plate and the upper pallet at the same time is arranged under each upper pallet, so as to improve the structural strength of the upper pallet and the side bedknife. The U-shaped blade grooves 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com