Paper knife sharpening method

A cutting tool and sharpening technology, which is applied in the field of tool grinding and processing technology, can solve the problems of frequent regrinding and easy wear of paper cutting tool edges, and achieve the effects of reducing the number of regrinding, improving operating efficiency and economic benefits, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The method for paper cutter sharpening of the present invention, the method is carried out according to the following steps:

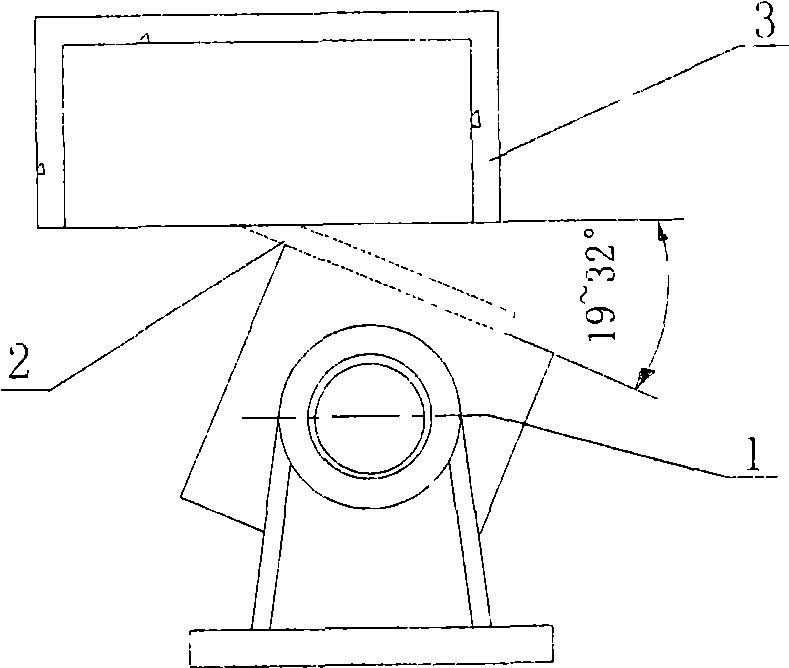

[0019] Step 1: Clamp the tool to be ground on the surface grinder, and adjust the angle between the tool and the grinding surface of the grinding wheel to be 19-32°;

[0020] Step 2: Use a large grinding head for rough grinding, and grind the edge of the paper cutter;

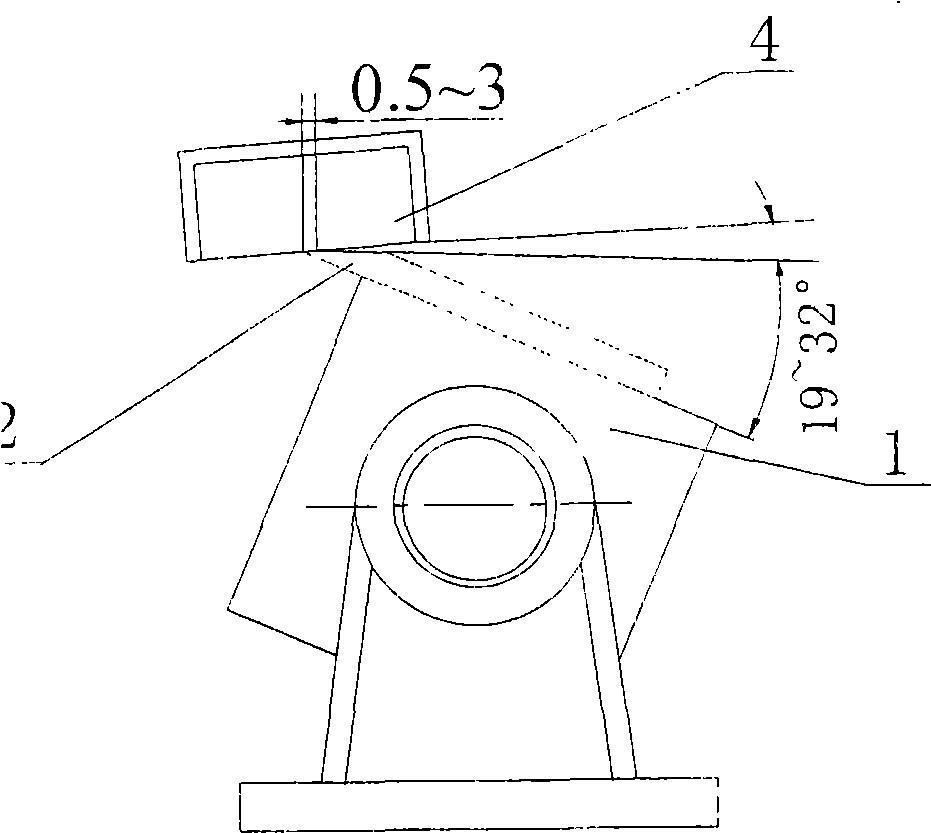

[0021] Step 3: Grind the angle according to step 1, adjust the angle between the tool and the grinding surface of the grinding wheel, start the small grinding head to finely grind the inclination angle of the paper cutting blade, and its width is between 0.5 and 3.0 mm;

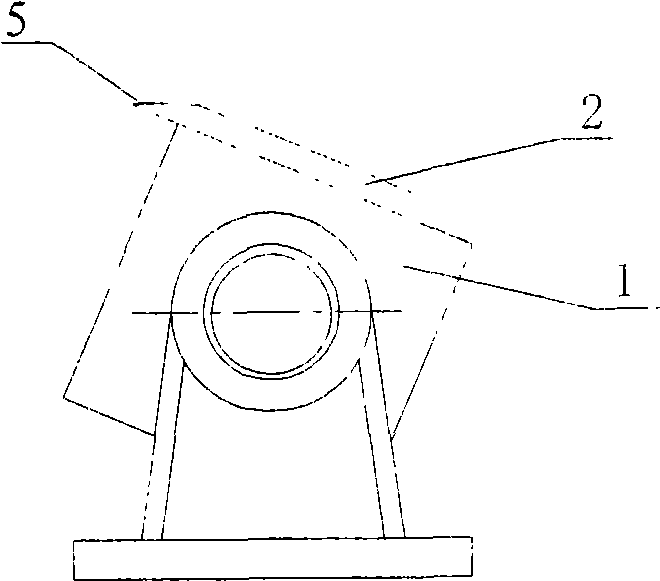

[0022] Step 4: In the process of finely grinding the inclination angle of the paper-cutting blade with the small grinding head, use an oil stone behind the small grinding head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com