Suspension conveyance apparatus

A handling device and suspended technology, applied in the directions of transportation and packaging, unpowered systems, railway car body parts, etc., can solve the problems of inability to reliably prevent lateral movement, difficult to support tools for objects to be transported, and high overall equipment costs. The effect of easy implementation, easy configuration, simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the suspended transport device proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Describe in detail.

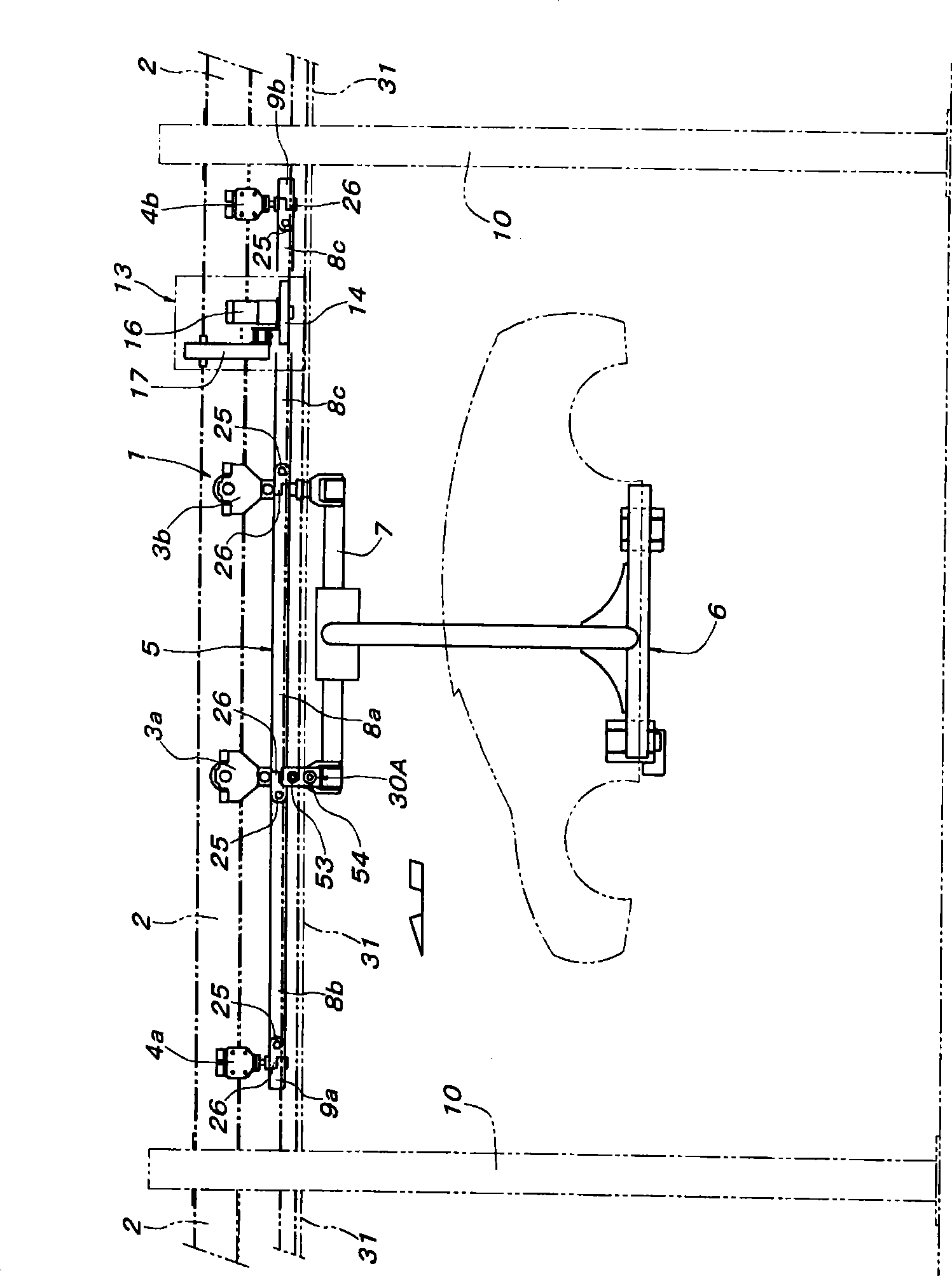

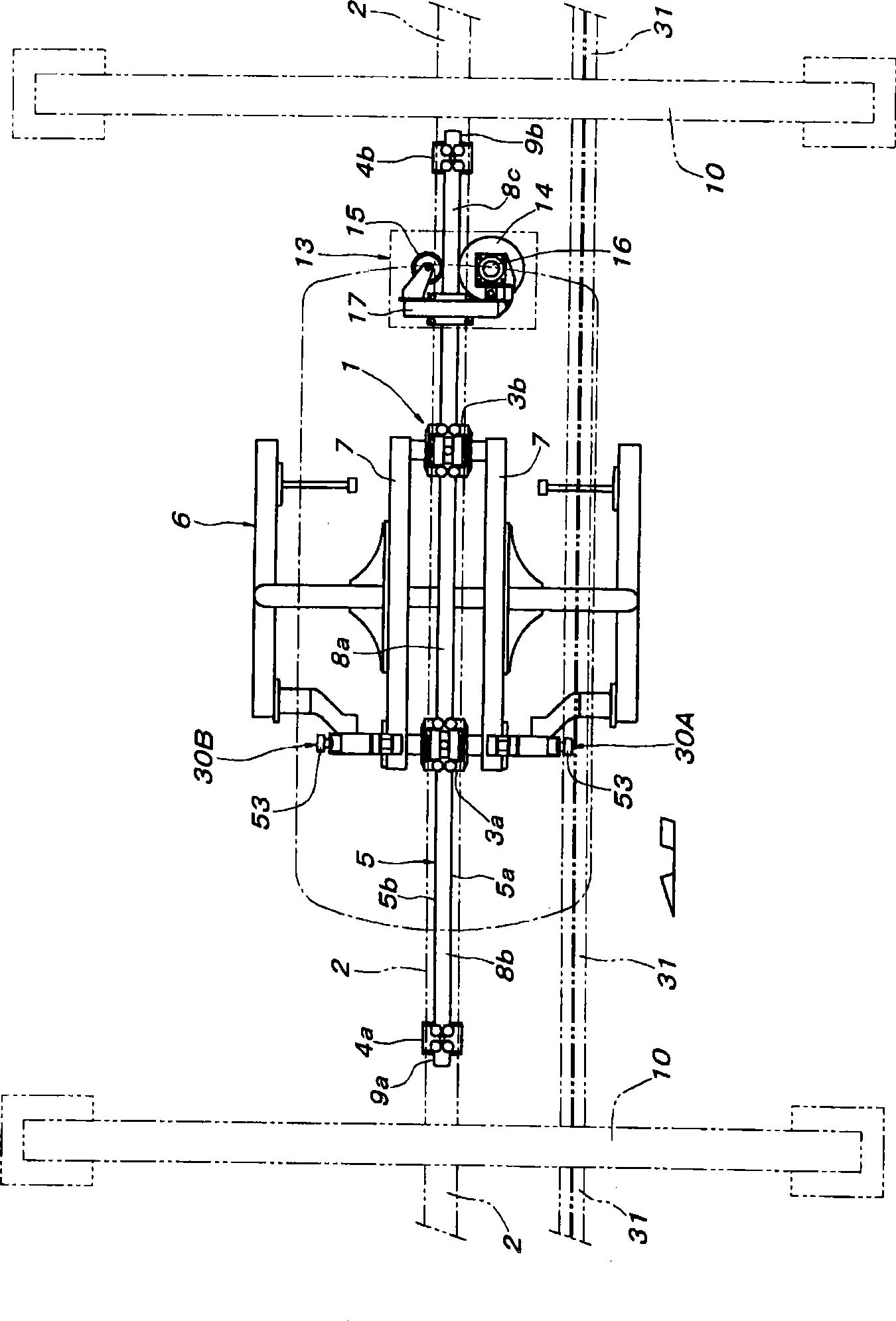

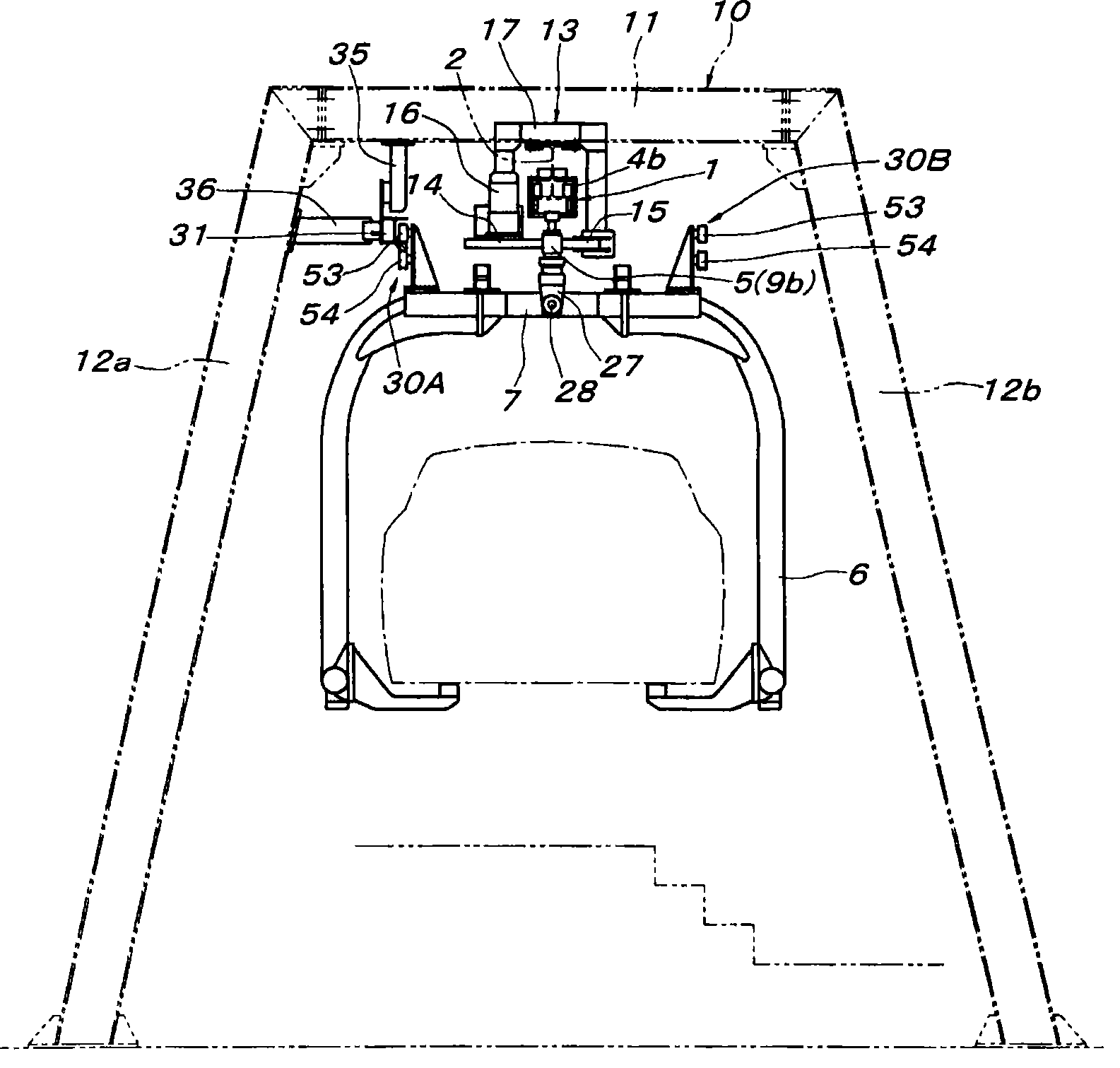

[0038] see Figure 1 to Figure 3 Shown are side schematic diagrams, top schematic diagrams, and rear schematic diagrams of the moving body for conveyance and the friction drive mechanism in the moving path, respectively.

[0039] exist Figure 1 ~ Figure 3 Among them, the mobile body 1 for conveying includes four trolleys (ie, a pair of front and rear load trolleys 3a, 3b in the middle, and a pair of front and rear trolleys 3a, 3b) that can be moved by fastening on the mobile guide rail 2 erected at a predetermined height on the ground. The unloaded trolleys 4a and 4b at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com