Oil modified phenolic resin connection material and preparation thereof

A technology of phenolic resin and connecting material, applied in the field of linear terminal methylol p-alkyl phenolic resin connecting material and its preparation process, and connecting material for engraving gravure ink, can solve the problems of long transparent time and become turbid, and achieve fast fixing speed Fast, stable viscosity, good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

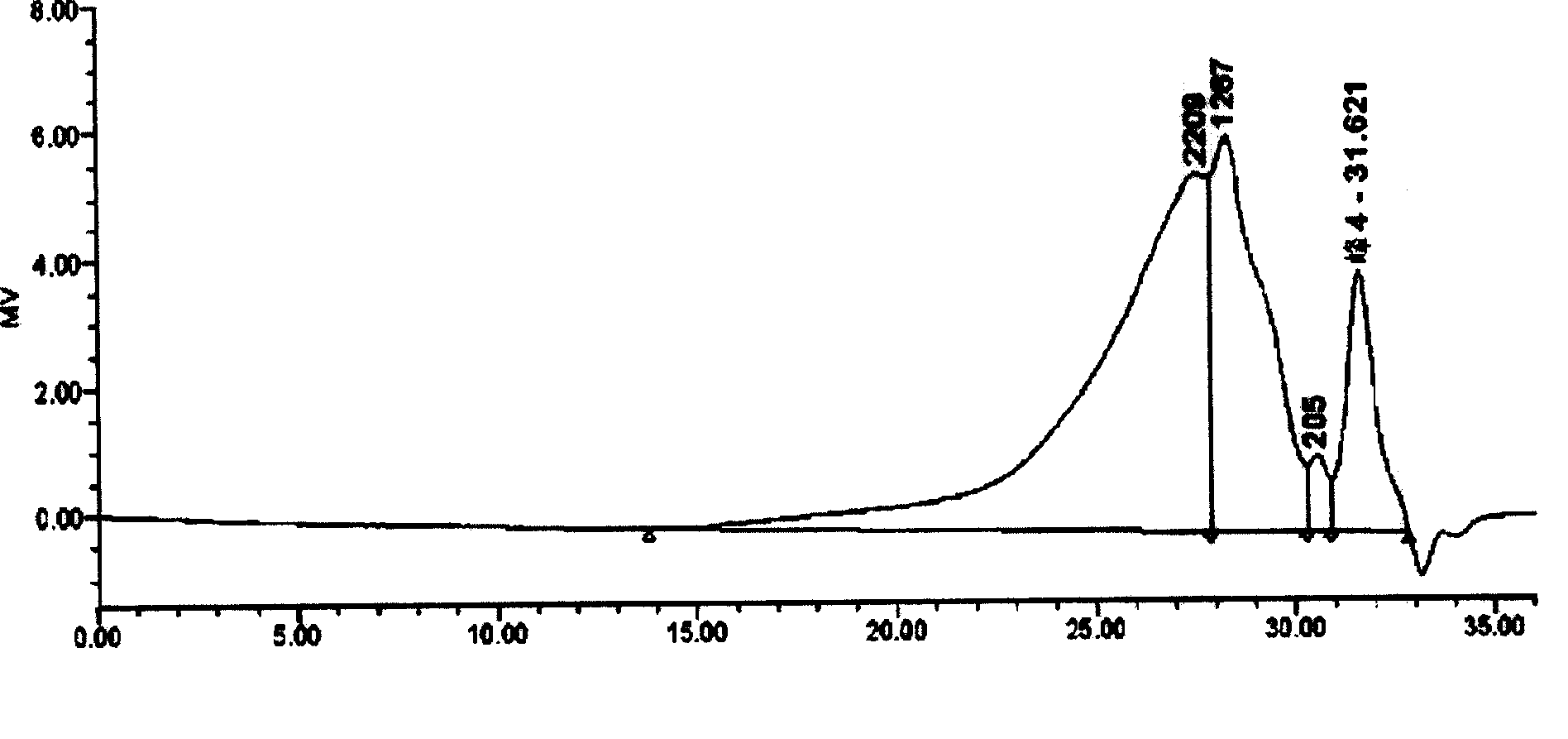

Embodiment 1

[0085] Embodiment 1: A novel oil-modified phenolic resin binder.

[0086]The formulation composition of the oil-modified phenolic resin binder includes: 44% of a mixture of tung oil and linseed oil, 40% of phenolic resin, and 16% of dodecane.

[0087] Above-mentioned phenolic resin connecting material adopts following method to make:

[0088] (1) Vegetable oil is added to the reaction kettle, and nitrogen gas is introduced at the same time, the temperature is raised to about 155° C., and the nitrogen gas is stopped;

[0089] (2) After adding phenolic resin for heat preservation, nitrogen gas is introduced;

[0090] (3) The temperature of the reaction kettle is raised to about 205°C and kept warm;

[0091] (4) Measure the viscosity. When the viscosity reaches 100.0pa.s / 40°C, cool down to 170°C and add dodecane;

[0092] (5) Heat up to about 210°C, keep warm, measure the viscosity, when the viscosity is 25.0~45.0pa.s / 40°C, cool down;

[0093] (6) Cool down to 100±2°C, keep w...

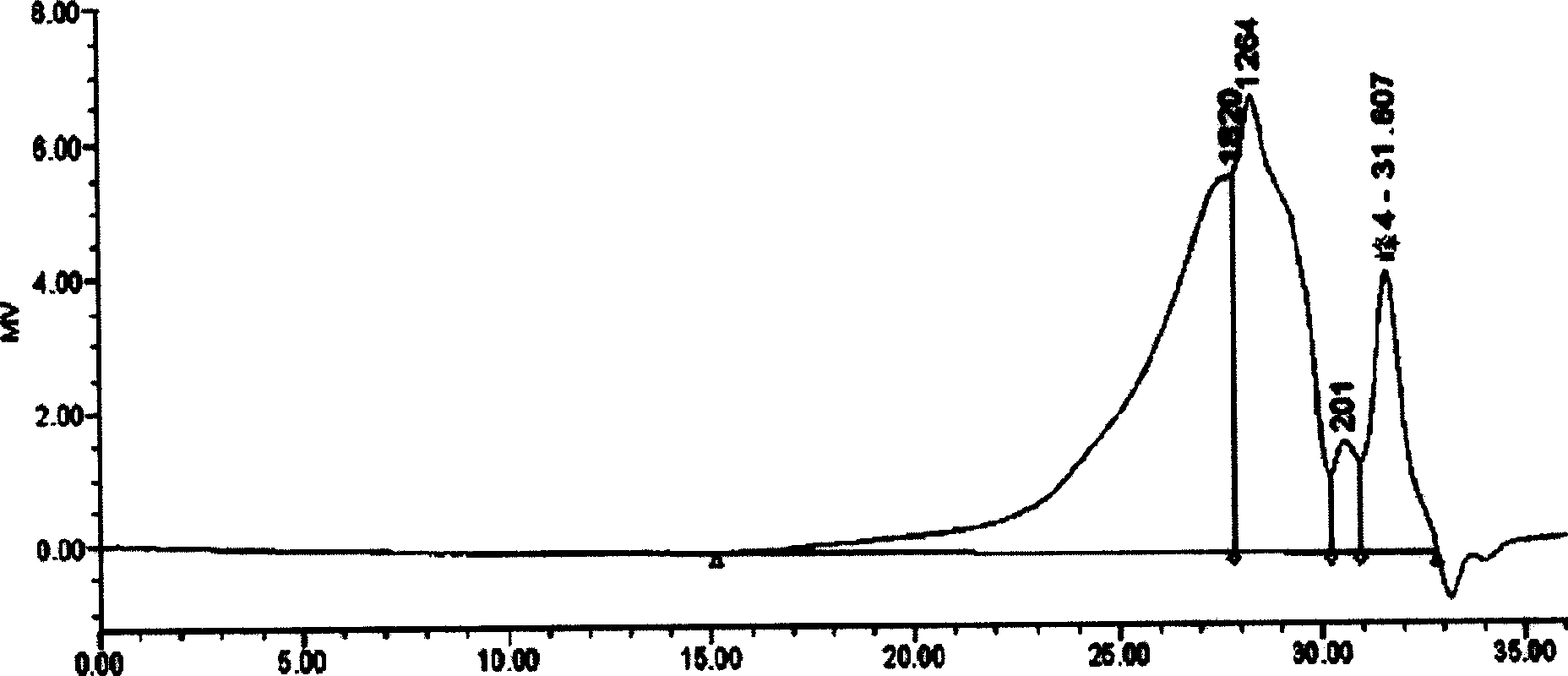

Embodiment 2

[0094] Embodiment 2: A kind of novel oil-modified phenolic resin binder

[0095] The formulation composition of the binder includes: 38% tung oil, 42% phenolic resin, 20% undecane.

[0096] Above-mentioned phenolic resin connecting material adopts following method to make:

[0097] (1) Vegetable oil is added to the reaction kettle, and nitrogen gas is introduced at the same time, the temperature is raised to about 160° C., and the nitrogen gas is stopped;

[0098] (2) After adding phenolic resin for heat preservation, nitrogen gas is introduced;

[0099] (3) The temperature of the reaction kettle is raised to about 215°C and kept warm;

[0100] (4) Measure the viscosity. When the viscosity reaches 75.0pa.s / 40°C, cool down to 160°C and add undecane;

[0101] (5) Raise the temperature to about 200°C, keep it warm, measure the viscosity, and when the viscosity is 35.0pa.s / 40°C, cool down;

[0102] (6) Cool down to 120±2°C, keep warm, measure viscosity, wait until the viscosit...

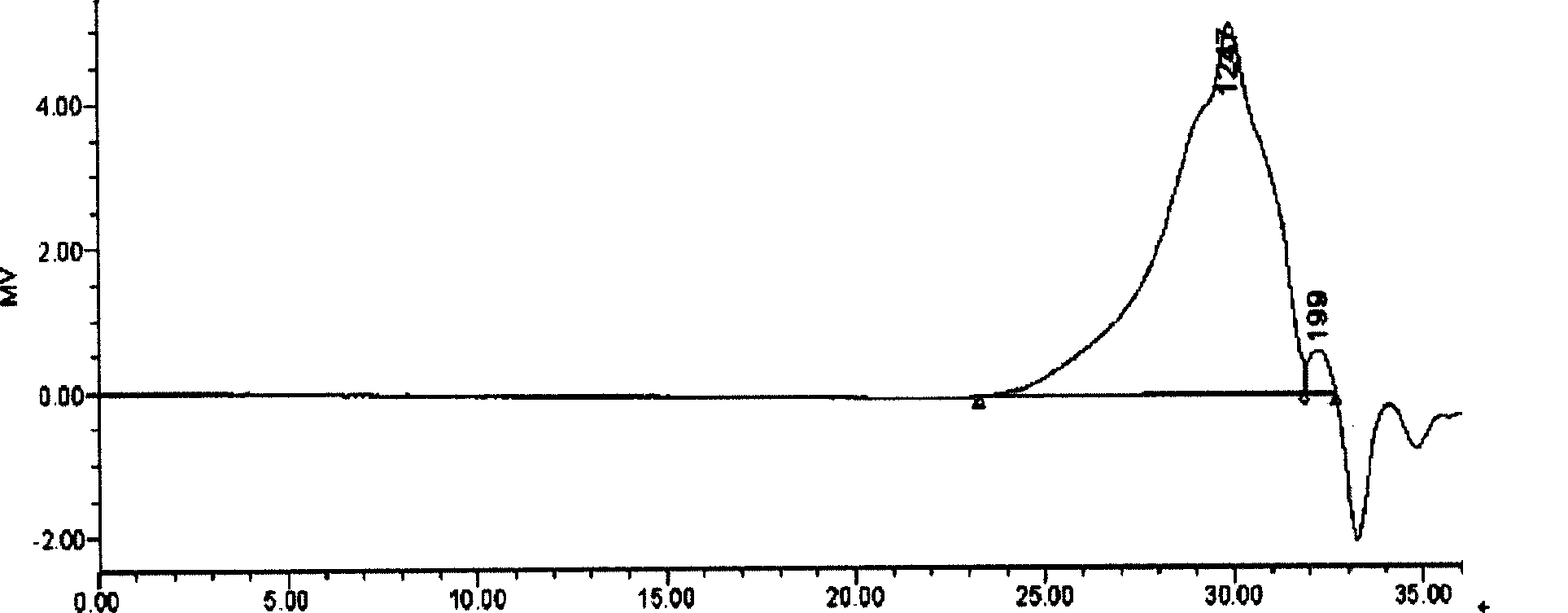

Embodiment 3

[0103] Embodiment 3: A novel oil-modified phenolic resin binder

[0104] The formulation composition of the phenolic resin binder comprises: 38% of a mixture of tung oil and linseed oil, 38% of phenolic resin, and 24% of tridecane.

[0105] The above-mentioned oil-modified phenolic resin binder is prepared by the following method:

[0106] (1) Vegetable oil is added to the reaction kettle, and nitrogen gas is introduced at the same time, the temperature is raised to about 150° C., and the nitrogen gas is stopped;

[0107] (2) After adding phenolic resin for heat preservation, nitrogen gas is introduced;

[0108] (3) The temperature of the reaction kettle is raised to about 210°C and kept warm;

[0109] (4) Measure the viscosity. When the viscosity reaches 140.0pa.s / 40°C, cool down to 170°C and add tridecane;

[0110] (5) Heat up to about 220°C, keep warm, measure the viscosity, when the viscosity is 25.0~45.0pa.s / 40°C, cool down;

[0111] (6) Cool down to 130±2°C, keep war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com