Automatic high-efficiency water-discharge deodorant floor drain

An automatic and high-efficiency technology, applied in water supply installations, indoor sanitary piping installations, buildings, etc., can solve problems such as inability to automatically drain water, affect the drainage efficiency of floor drains, and short deodorizing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

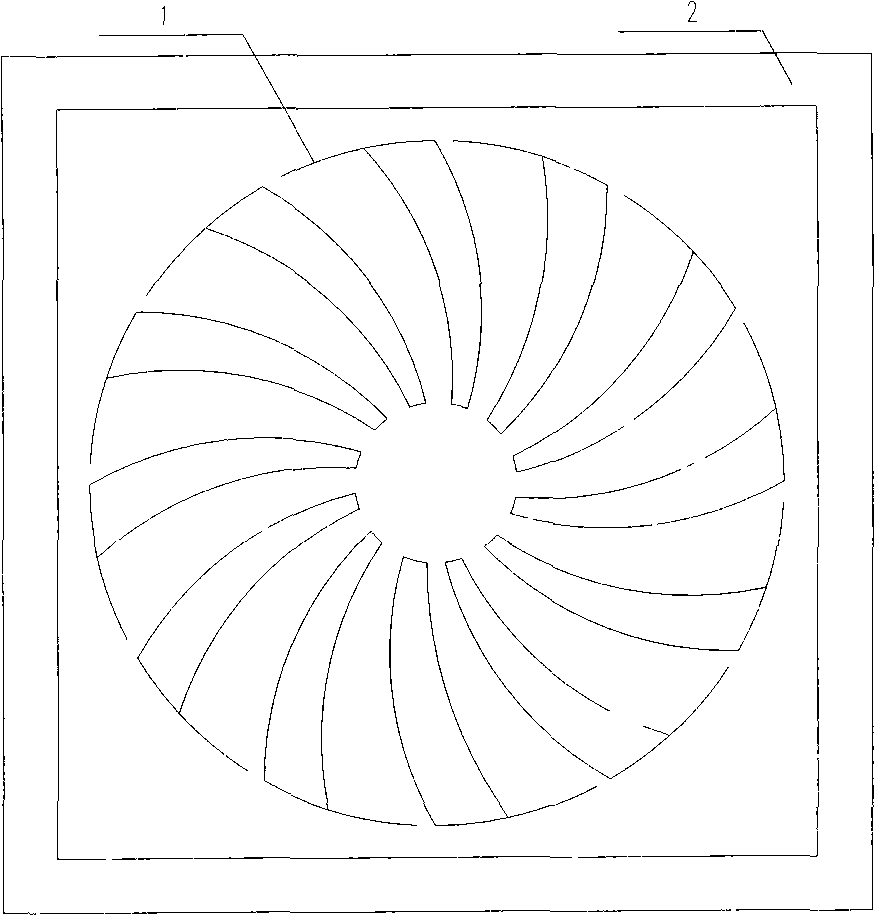

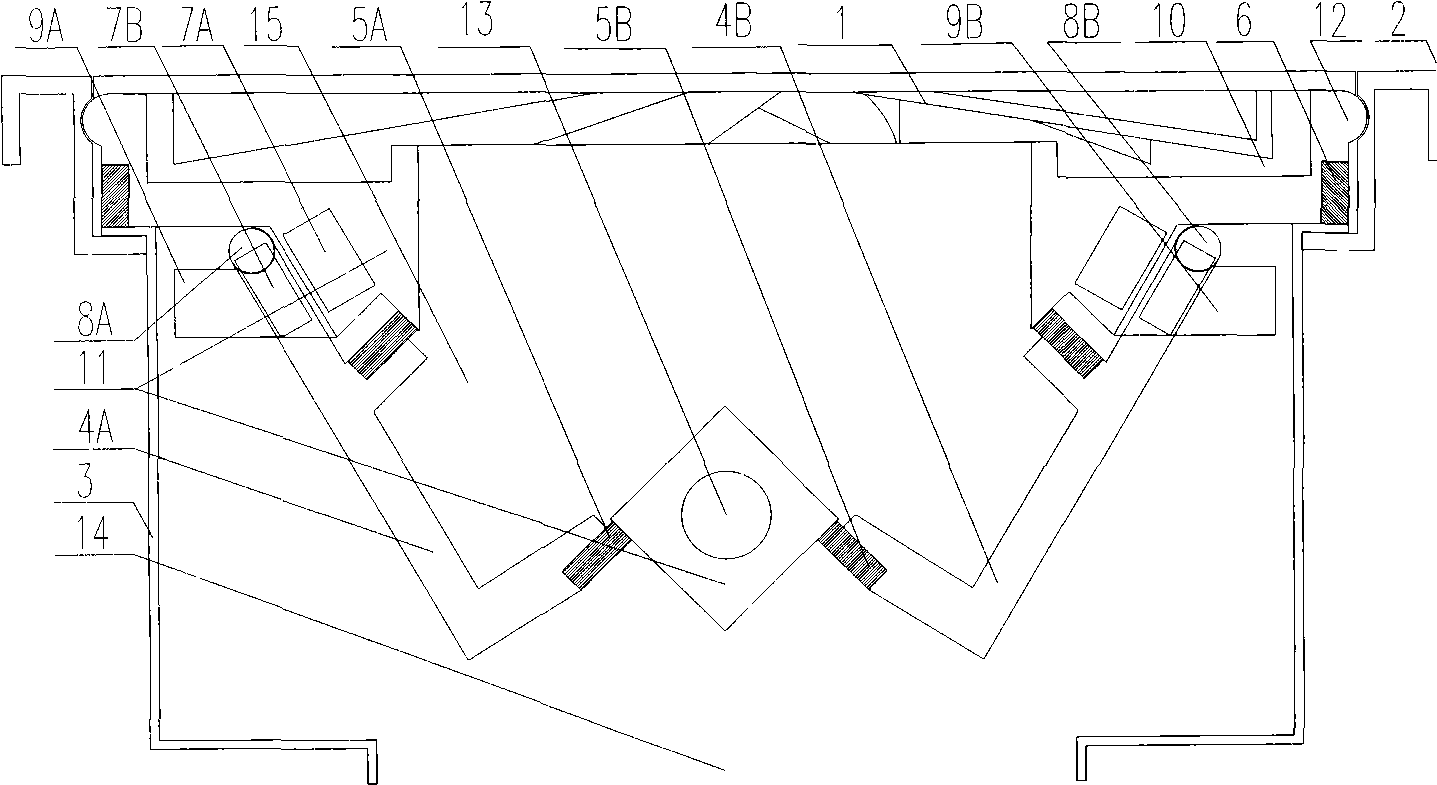

[0019] Such as figure 2 As shown, the shell part of the floor drain can be made of stainless steel and formed by stamping, or it can be made of copper and formed by casting. The surface of the floor drain can be polished into a mirror surface, a stripe surface or chrome-plated to enhance the appearance, and the deflector of the grate 1 can be made into a straight or curved shape, and the floor drain of the present invention is a curved shape. The center of the grate 1 can be perforated for drainage of the washing machine.

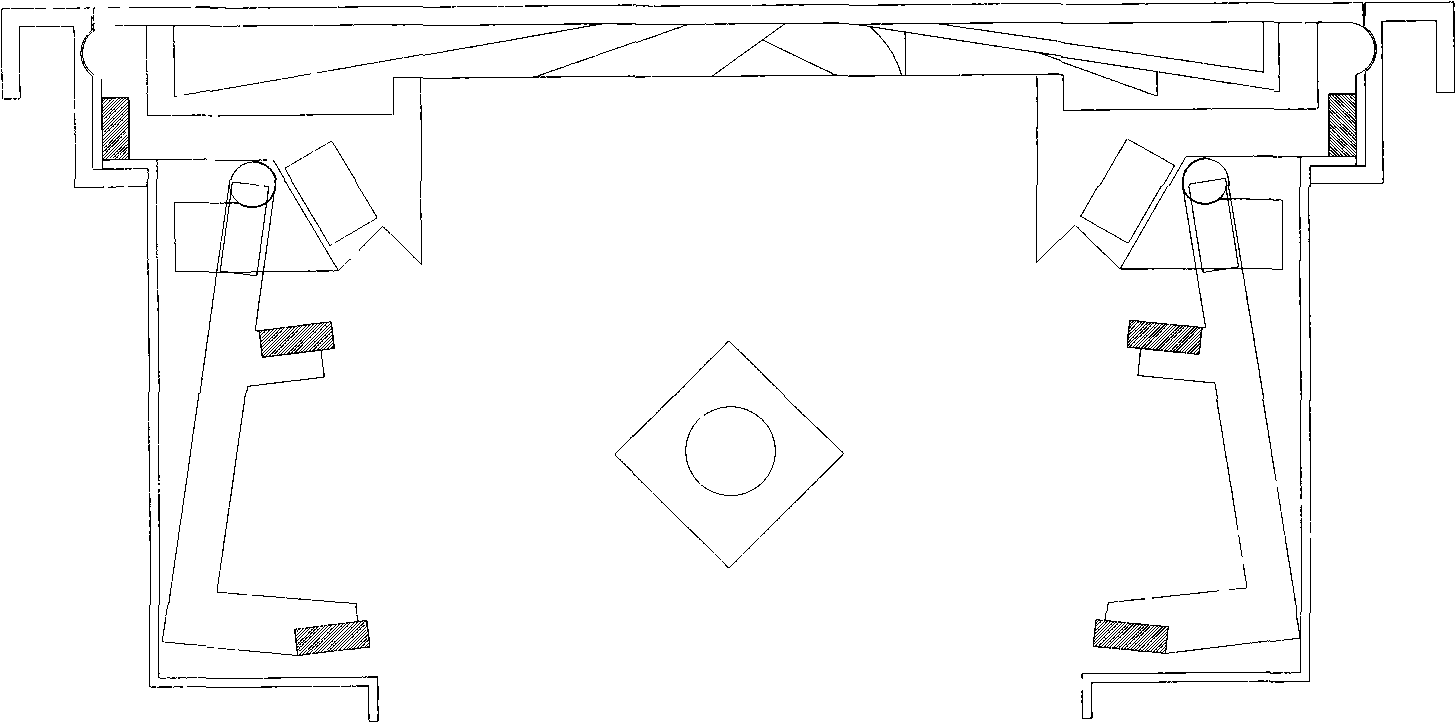

[0020] Such as figure 2 Shown, the floor drain inner shell part is made of plastics, movable baffle 4A, 4B, rotating shaft 8A, 8B and reinforcing magnet 7B one-time injection molding (as image 3 Shown), strengthening magnet 7A, axle seat 9A, 9B, water storage tank 10, main body 11, salient point 12 and round hole 13 one-time injection molding.

[0021] this invention figure 1 , figure 2 , image 3 , Figure 4 The thickness of the floor drain shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com