Gear change control system of automatic transmission

A technology for automatic transmissions and control systems, applied in the direction of transmission control, elements with teeth, belts/chains/gears, etc., which can solve problems such as difficult to move shift protrusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

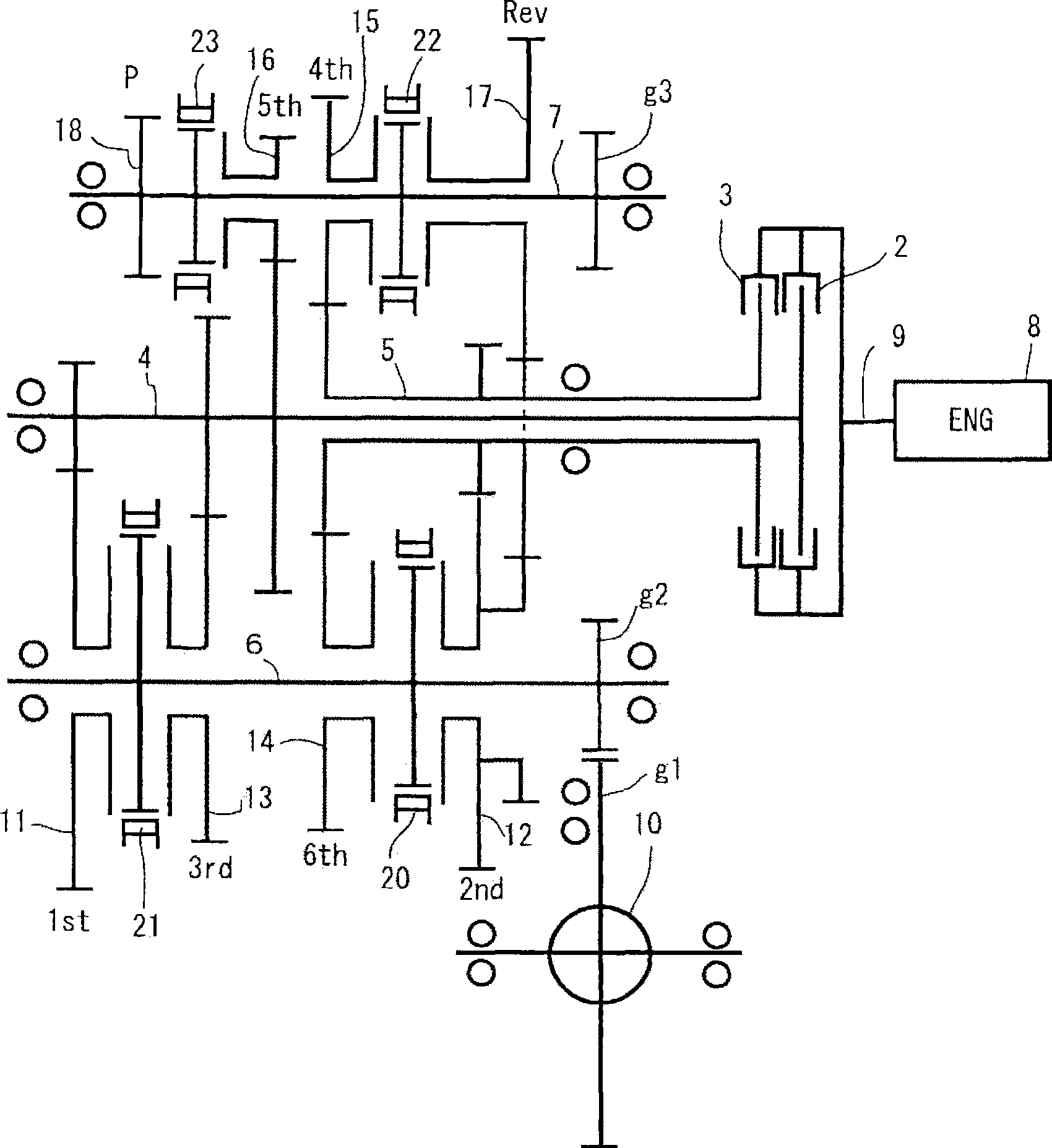

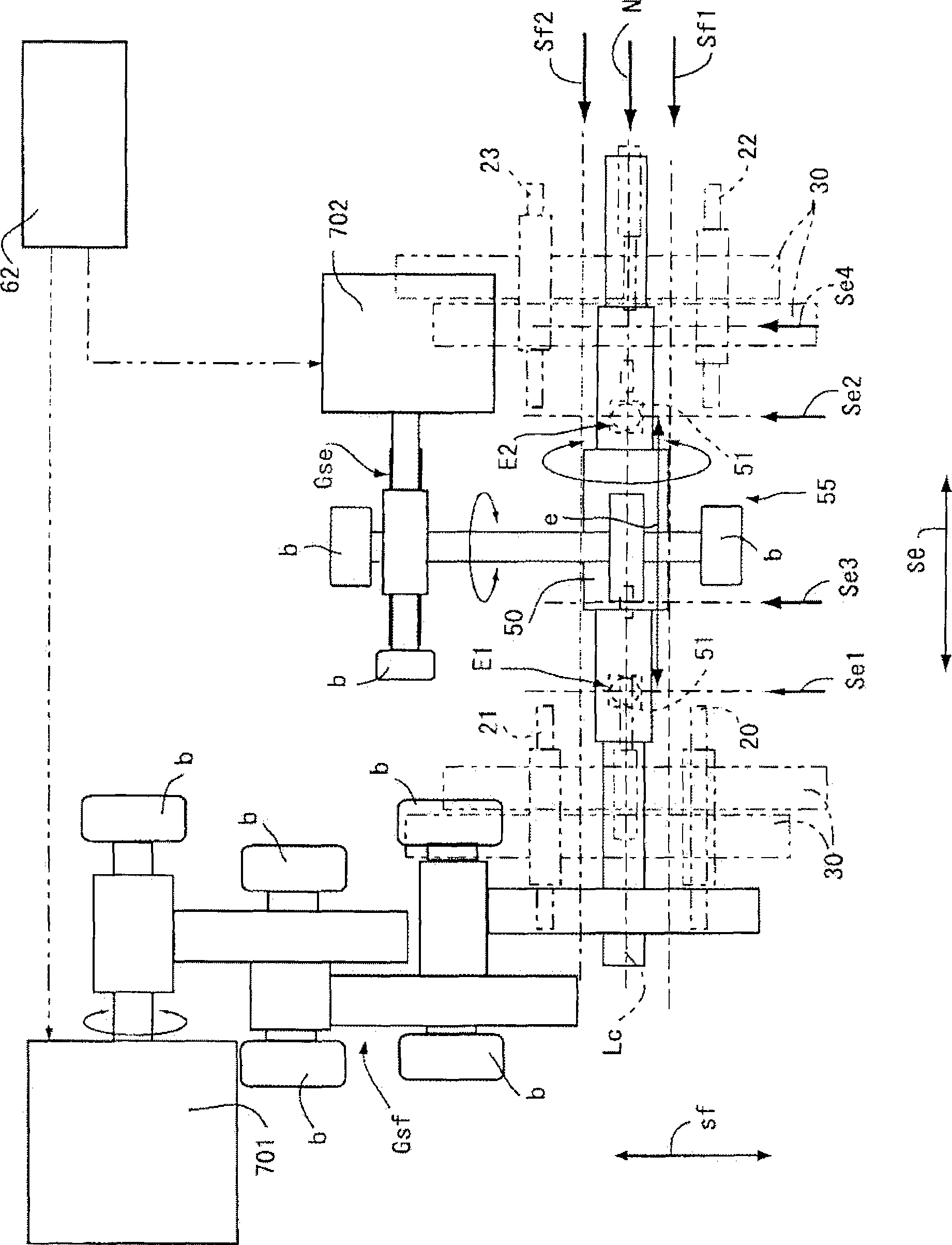

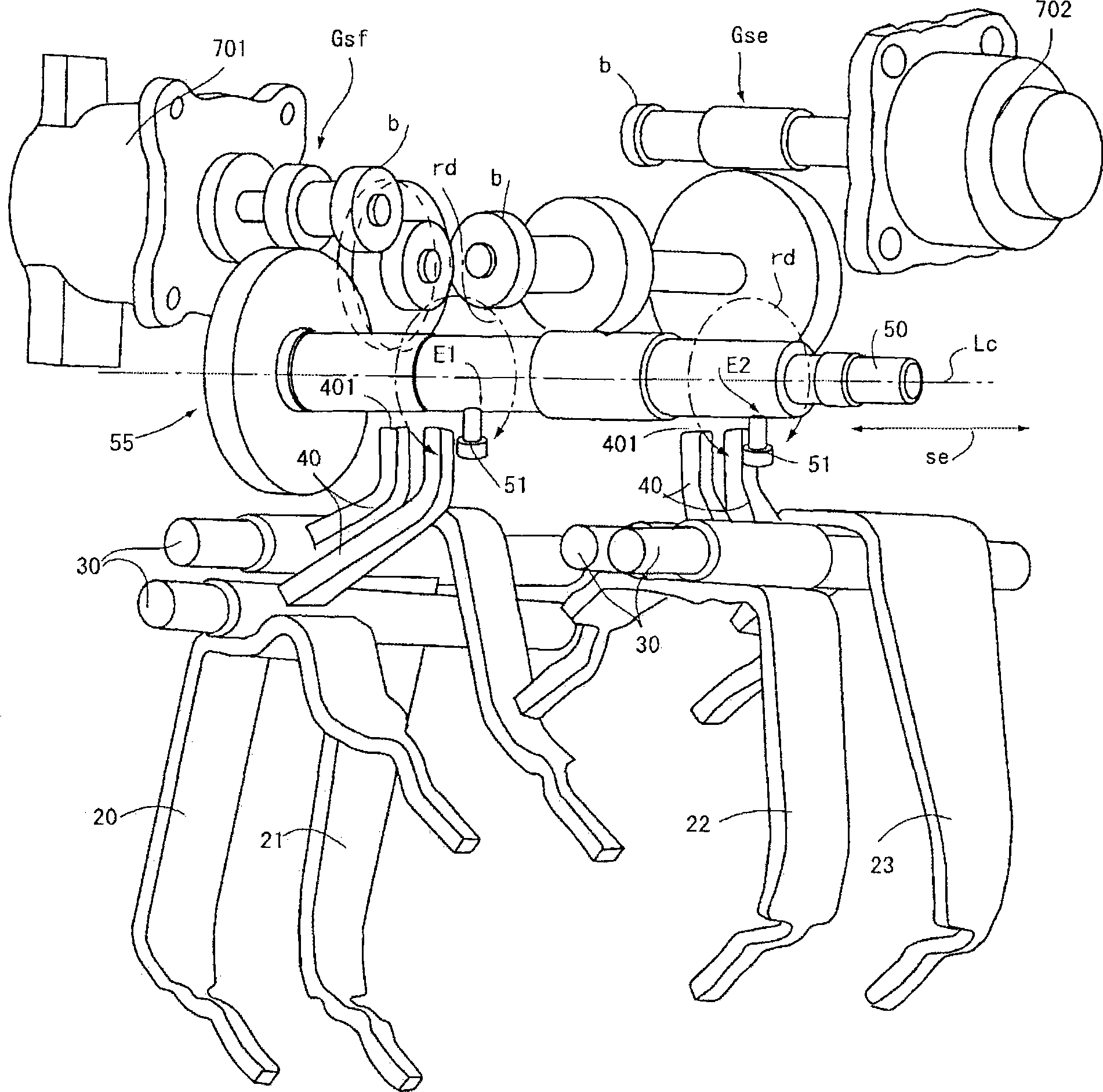

[0042] Subsequently, the shift control system of an automatic transmission as an embodiment of the present invention will refer to figure 1 and 2 to describe.

[0043] like figure 1 The automatic transmission 1 shown is a double clutch transmission and comprises two clutches 2, 3, two main shafts 4, 5 and two layshafts 6, 7 arranged concentrically with each other. Power is transmitted from a driving force transmission shaft 9 that transmits driving force from an engine 8 to the first main shaft 4 through a first clutch 2 , and power is transmitted from the driving force transmission shaft 9 to the second main shaft 5 through a second clutch 3 . Note that the two clutches are controlled to be engaged or disengaged by control circuits not shown (eg, hydraulic, electrical, or mechanical control circuits).

[0044] The first layshaft 6 and the second layshaft 7 are arranged spaced apart from each other such that their axes are parallel to the first main shaft 4 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com