Energy-conserving control method for adjusting water pump number in synchronization speed changing flow quantity changing heating system

A heating system, energy-saving control technology, applied in the heating system, space heating and ventilation details, heating methods, etc., can solve the problems of constant application, high energy consumption, unreasonable adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

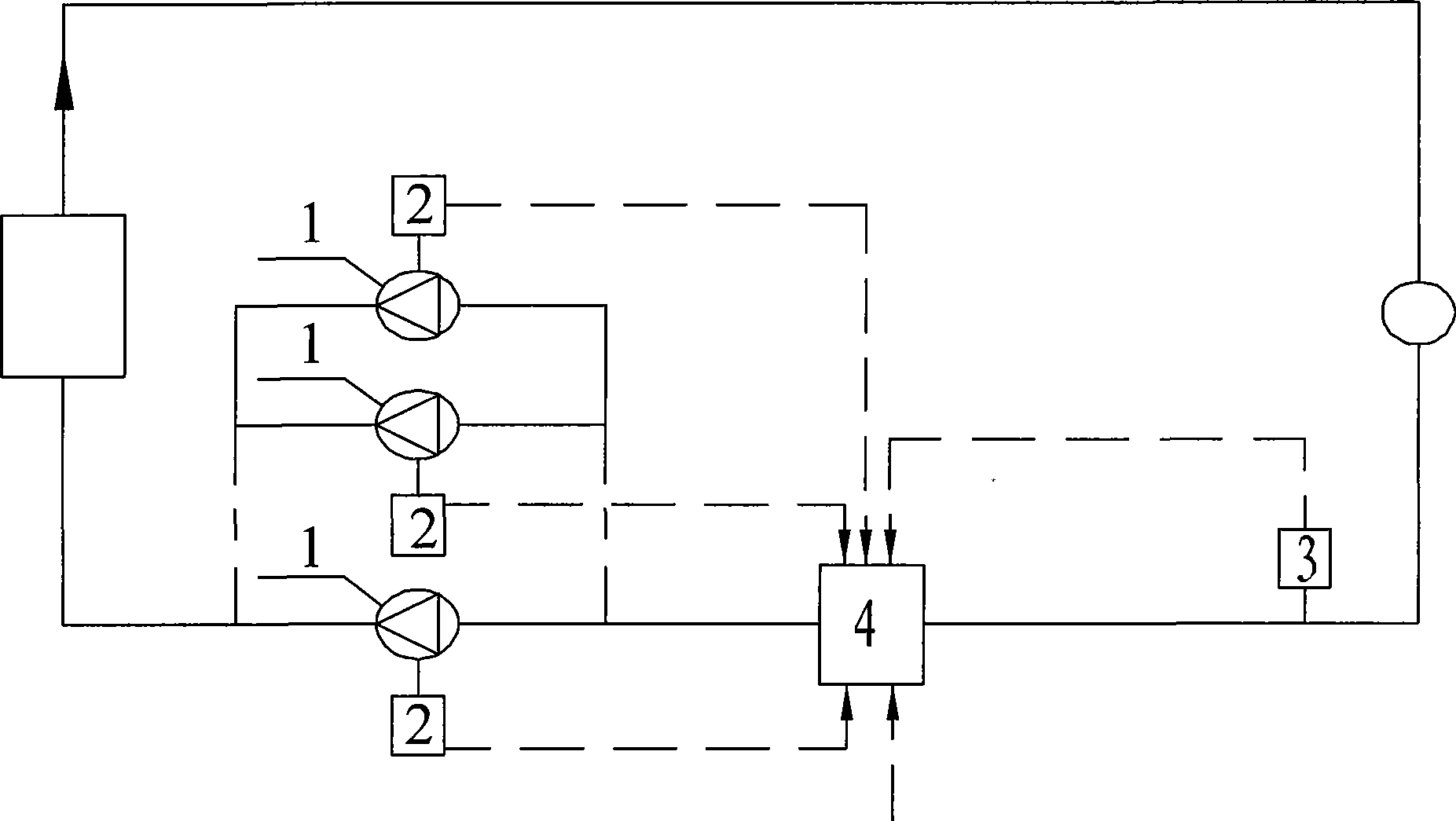

[0014] Specific implementation mode two: combination figure 1 Describe this embodiment, the steps of this embodiment are as follows:

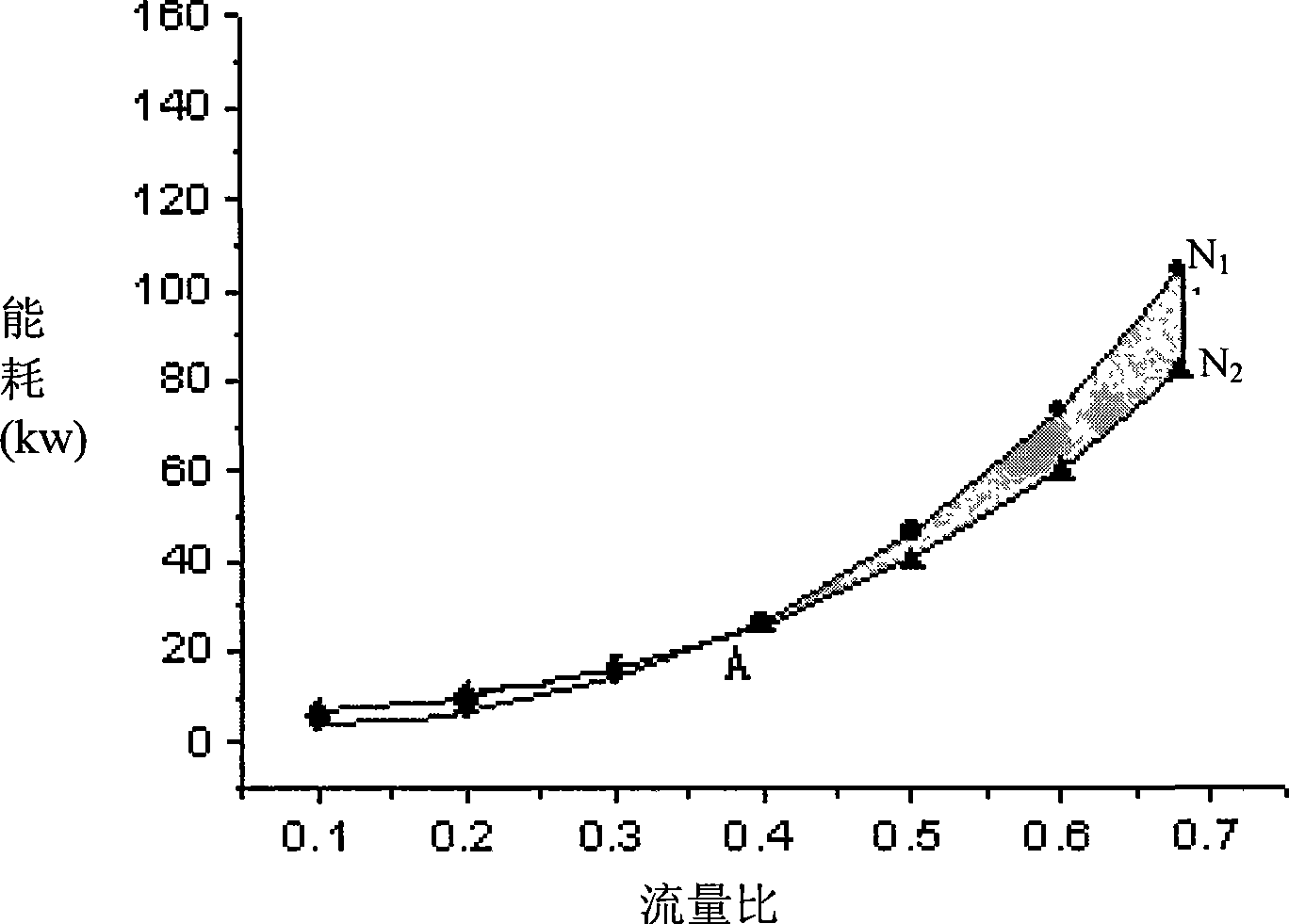

[0015] Step 1: Initialize the controller 4; set the single water pump 1 provided in the sample of the selected model water pump 1 at the rated speed n 0 The flow rate, lift, power and efficiency values of the lower operating point are input into the controller 4, and the controller 4 obtains the characteristic curve of a single water pump 1 through mathematical fitting; the controller 4 obtains the parallel synchronous The characteristic curve at the time of frequency conversion speed regulation; then input the set flow rate of the heating network pipe network and the pipe network resistance under the set flow rate into the controller 4, and the controller 4 calculates the resistance characteristic curve of the pipe network; finally, the water pump motor and the pipe network resistance The efficiency of the water pump inverter is input into ...

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment is a further description of step 1 in Embodiment 1. Step 1 is to turn the single water pump 1 provided in the sample of the selected model water pump 1 at the rated speed n 0 The flow, head, power and efficiency values of the lower operating point are input into the controller 4; the controller 4 uses the least square method to perform polynomial fitting on the input data, and the form of the polynomial is as formula 1:

[0019] H = H 0 + A 1 Q + A 2 Q 2 N = ...

specific Embodiment approach 4

[0044] Embodiment 4: This embodiment is a further description of Step 2 in Embodiment 1. Step 2 is to input the design working point parameters of the pipe network into the controller 4, and the resistance of the pipe network can be obtained according to formula 4. The resistance characteristic coefficient S of the pipe network in the characteristic curve formula, and then the efficiency of the water pump motor obtained by formula 5 and the efficiency of the water pump frequency converter obtained by formula 6 are input into the water pump frequency converter 2, and the water pump 1 should meet when switching Conditions for flow, head and efficiency to be equal:

[0045] Q i = Q i - 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com