Buffering device for balance lever of nuclear plant crane lifting mechanism

A technology of balancing lever and lifting mechanism, applied in the field of buffer devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

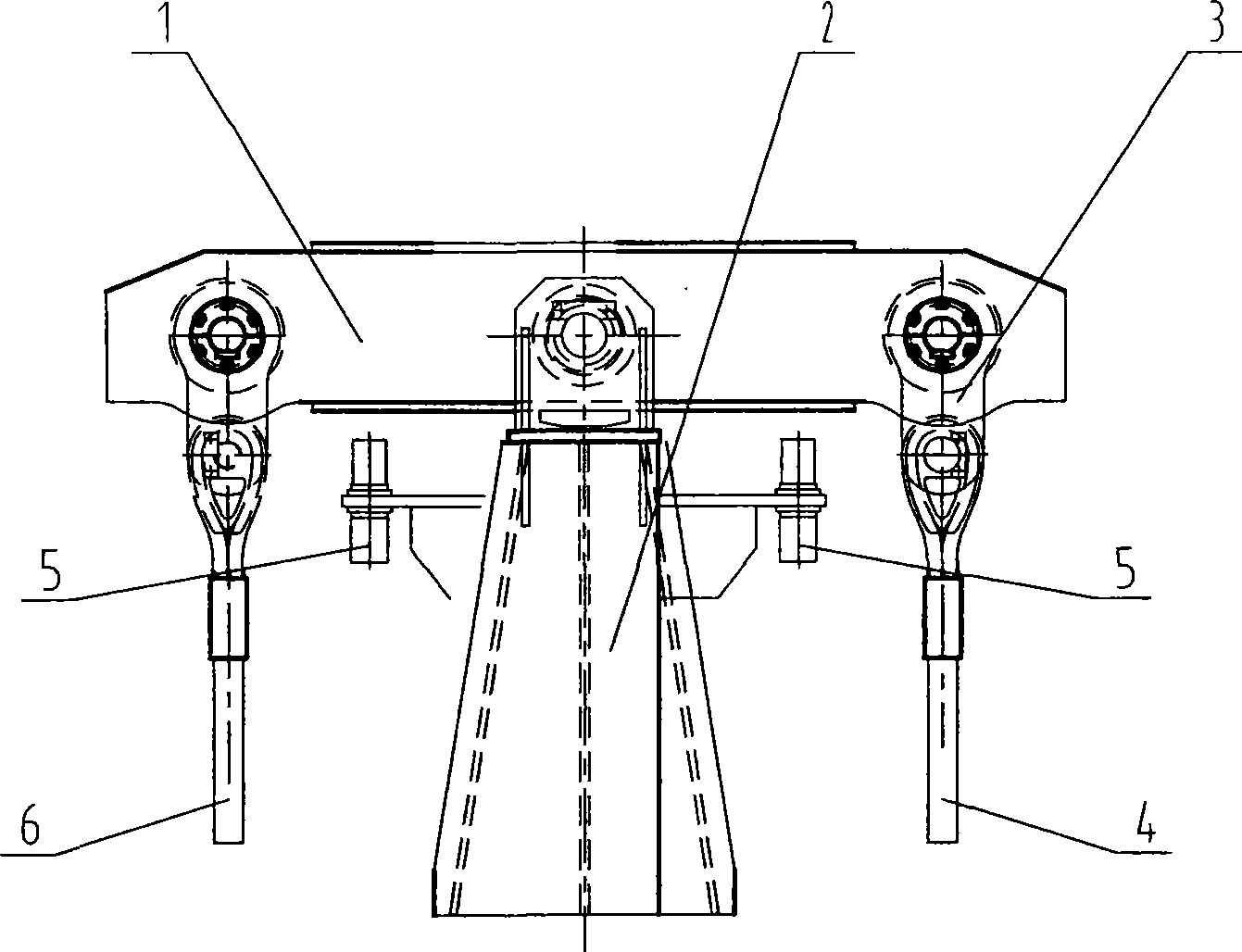

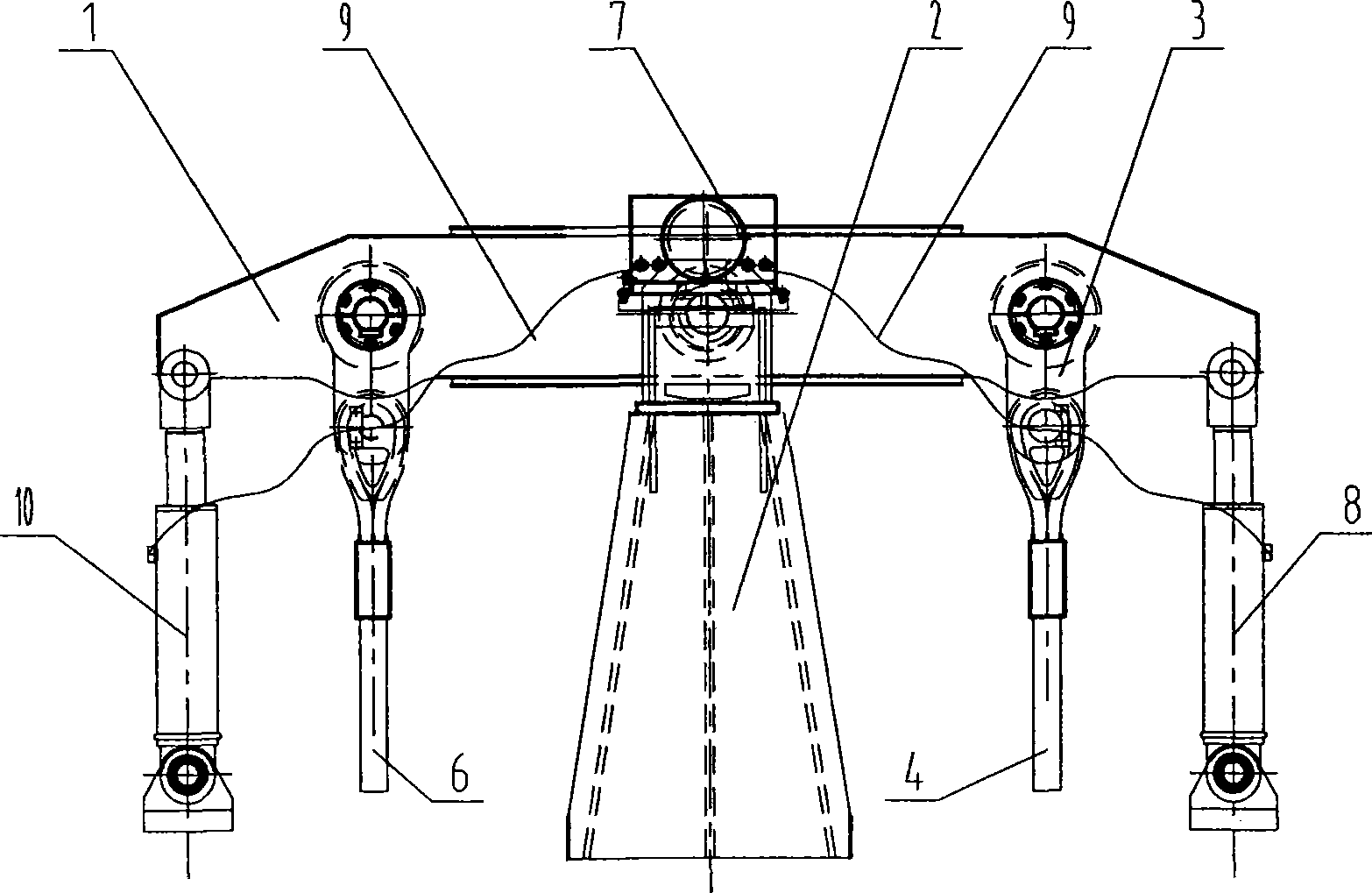

[0010] Such as figure 2 As shown, a buffer device for the balance lever of the hoisting mechanism of a nuclear power plant crane is composed of a balance lever (1), a support (2), a left steel wire rope (6), and a right steel wire rope (4). The middle of the balance lever (1) Installed on the support (2), the left wire rope (6) and the right wire rope (4) are symmetrically installed on both sides of the balance lever (1) through the collar (3), and the two ends of the balance lever (1) They are respectively connected with the pistons of the left oil cylinder (10) and the right oil cylinder (8), and the left oil cylinder (10) and the right oil cylinder (8) are connected to each other with the hydraulic system (7) through the oil pipe (9).

[0011] Since the left oil cylinder (10) and the right oil cylinder (8) are directly connected with the balance lever (1), when the right wire rope (4) fails, the right oil cylinder (8) immediately rises slowly, and the left oil cylinder (10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap