Aluminiferous low-carbon cold heading wire rod steel and production method thereof

A technology of cold heading and wire rod, applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of unfavorable steel full phase transformation, reduced drawing and cold heading performance, and high spinning temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

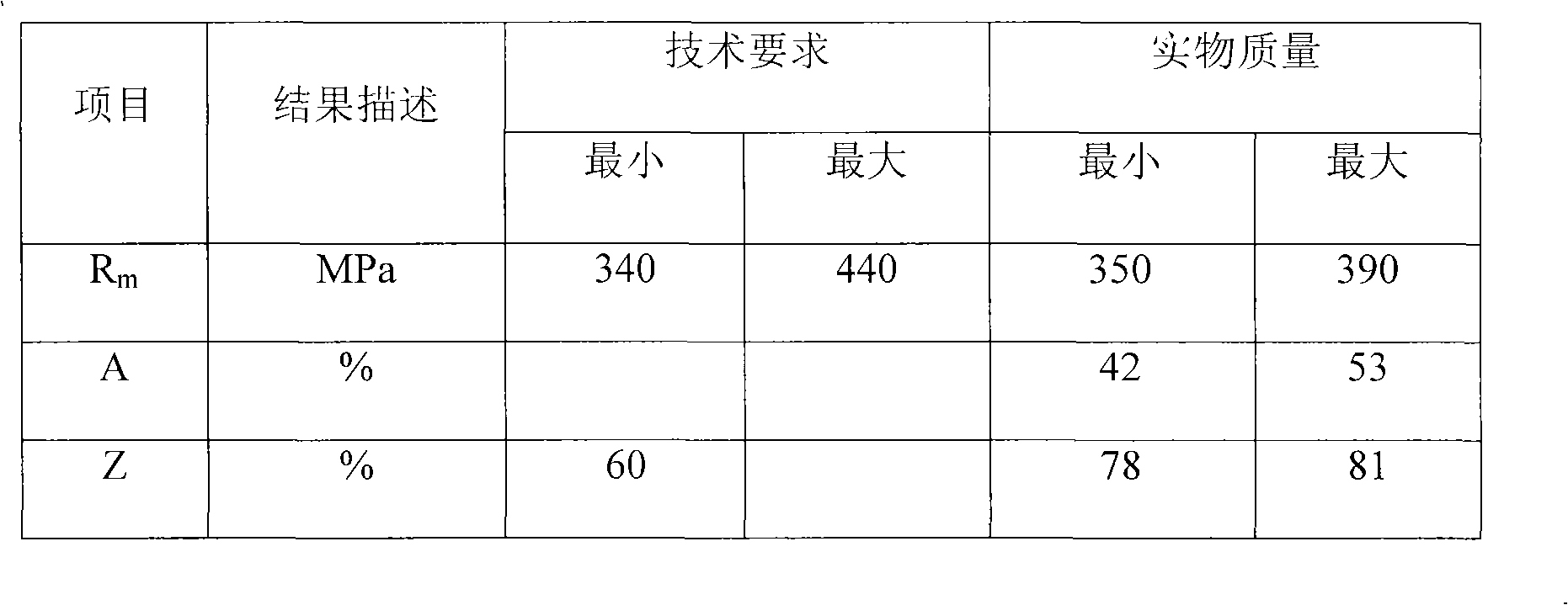

Examples

Embodiment 1

[0026] A kind of aluminum-containing low-carbon cold heading wire rod steel, its chemical composition and weight percentage are: C: 0.04, Si: 0.01, Mn: 0.35, P: 0.03, S: 0.035, Als: 0.02, the rest is Fe and not Avoid impurities.

[0027] A method for producing aluminum-containing low-carbon cold heading wire rod steel, the steps of which are:

[0028] 1) Heat the continuous casting slab to 950°C, and the cross-sectional temperature difference is 30°C;

[0029] 2) Rolling: the starting rolling temperature is controlled at 900°C, and the final rolling temperature is controlled at 950°C;

[0030] 3) Spin silk after water cooling, and its spinning temperature is controlled at 880°C;

[0031] 4) Cool to 615°C after spinning, and the cooling rate is controlled at 0.7°C / sec.

Embodiment 2

[0033] A kind of aluminum-containing low-carbon cold heading wire rod steel, its chemical composition and weight percentage are: C: 0.051, Si: 0.02, Mn: 0.40, P: 0.025, S: 0.032, Als: 0.028, the rest is Fe and not Avoid impurities.

[0034] A method for producing aluminum-containing low-carbon cold heading wire rod steel, the steps of which are:

[0035] 1) Heat the continuous casting slab to 980°C, and the cross-sectional temperature difference is 28°C;

[0036] 2) Rolling: the starting rolling temperature is controlled at 930°C, and the final rolling temperature is controlled at 960°C;

[0037] 3) Spin silk after water cooling, and its spinning temperature is controlled at 886°C;

[0038] 4) Cool to 630°C after spinning, and control the cooling rate at 0.8°C / sec.

Embodiment 3

[0040] A kind of aluminum-containing low-carbon cold heading wire rod steel, its chemical composition and weight percentage are: C: 0.060, Si: 0.032, Mn: 0.45, P: 0.020, S: 0.028, Als: 0.035, the rest is Fe and not Avoid impurities.

[0041] A method for producing aluminum-containing low-carbon cold heading wire rod steel, the steps of which are:

[0042] 1) Heating the continuous casting slab to 1000°C with a cross-sectional temperature difference of 20°C;

[0043] 2) Rolling: the starting rolling temperature is controlled at 950°C, and the finishing rolling temperature is controlled at 970°C;

[0044] 3) spinning after water cooling, the spinning temperature is controlled at 890°C;

[0045] 4) Cool to 650°C after spinning, and control the cooling rate at 0.9°C / sec.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com