Wall cloth manufacture compounding machine and compounding method

A composite machine and wall covering technology, which is applied in the direction of chemical instruments and methods, layered products, lamination devices, etc., can solve the problems that the composite of yarn and mixed decorative wall coverings cannot be realized, and the strength of the base paper is low, so as to achieve reliable composite , crisp lines, reliable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

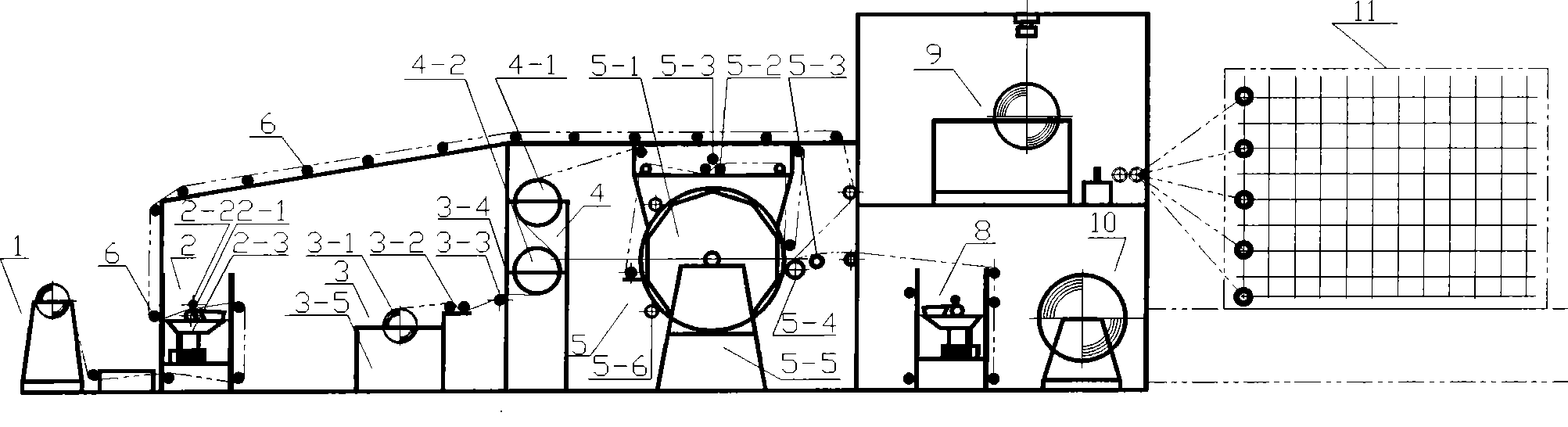

[0010] Embodiment 1: with reference to attached figure 1 . The compound machine for wall covering production consists of fabric sending frame 1, gluing devices 2 and 8, constant tension central winder 3, circulating water cooling roller 4, lamination drying roller group 5, multiple guide rollers 6, guide roller support 7 , yarn pan head 9, paper product sending frame 10 and yarn bobbin frame 11 constitute, the making of above-mentioned parts is prior art, do not narrate at this. Fabric sending rack 1, gluing device 2 and 6, constant tension central winder 3, circulating water cooling roller 4, laminating drying roller group 5, yarn pan head 7, paper sending rack 8 and yarn bobbin Between the frame 9 is the interval setting. The gluing devices 2 and 6 are composed of glue grooves 2-3 and 6-3, glue rollers 2-1 and 6-1 and pressure rollers 2-2 and 6-2, and glue rollers 2-1 and 6-1 are located at In the glue tanks 2-3 and 6-3, the pressure rollers 2-2 and 6-2 are located on the...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the composite method of wall cloth, the cloth surface that is positioned at fabric sending rack 1 is guided by a plurality of guide rollers 6, and passes through the gluing roller 2-1 in gluing device 2 and When the pressure roller 2-2 is between the faces, after the glued roller 2-1 and the pressure roller 2-2 are evenly coated with the required amount of glue, the guide rollers 6 along the guide roller stand 7 and the rollers located on the guide roller stand When the guide roller 5-3 on the vertical rod frame enters the compound gap formed by the roller surface of the laminating roller 5-4 and the cylinder surface of the large drying cylinder 5-1, the paper on one side of the laminating and drying roller group 5 The wallpaper on the product sending frame 10 is guided by the guide roller and when passing between the glue roller 8-1 and the pressure roller 8-2 in the gluing device 8, it is glued by the glue roller 8-1 and the ...

Embodiment 3

[0012] Embodiment 3: On the basis of Embodiment 1, the composite method of wall cloth, the cloth surface that is positioned at fabric sending rack 1 is guided by a plurality of guide rollers 6, and passes through the gluing roller 2-1 in gluing device 2 and When the pressure roller 2-2 is between the faces, after the glued roller 2-1 and the pressure roller 2-2 are evenly coated with the required amount of glue, the guide rollers 6 along the guide roller stand 7 and the rollers located on the guide roller stand When the guide roller 5-3 on the vertical rod frame enters the compound gap formed by the roller surface of the laminating roller 5-4 and the cylinder surface of the large drying cylinder 5-1, the paper on one side of the laminating and drying roller group 5 The wallpaper on the product sending frame 10 is guided by the guide roller and when passing between the glue roller 8-1 and the pressure roller 8-2 in the gluing device 8, it is glued by the glue roller 8-1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com