High-speed construction method of tunnel lining concrete

A construction method and concrete technology, applied in the direction of tunnel lining, wellbore lining, earthwork drilling and mining, etc., can solve problems affecting the progress of concrete lining, etc., to overcome repeated removal of gravel materials and setting of construction roads, speed up construction progress, The effect of saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

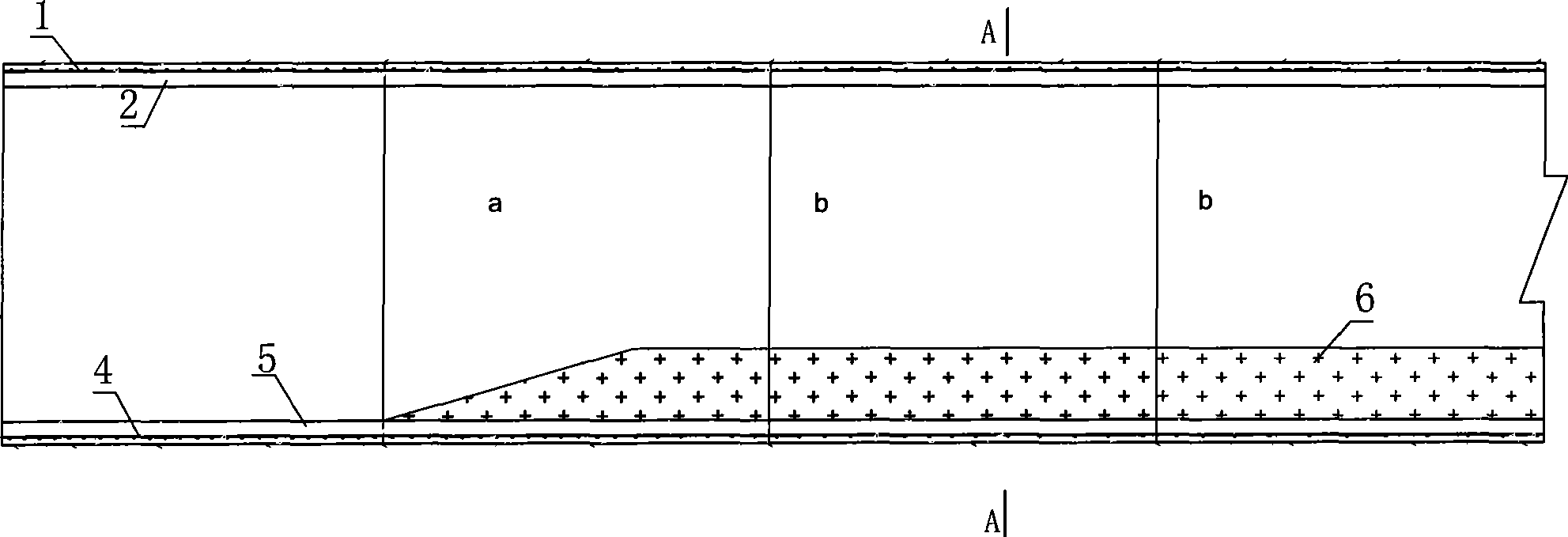

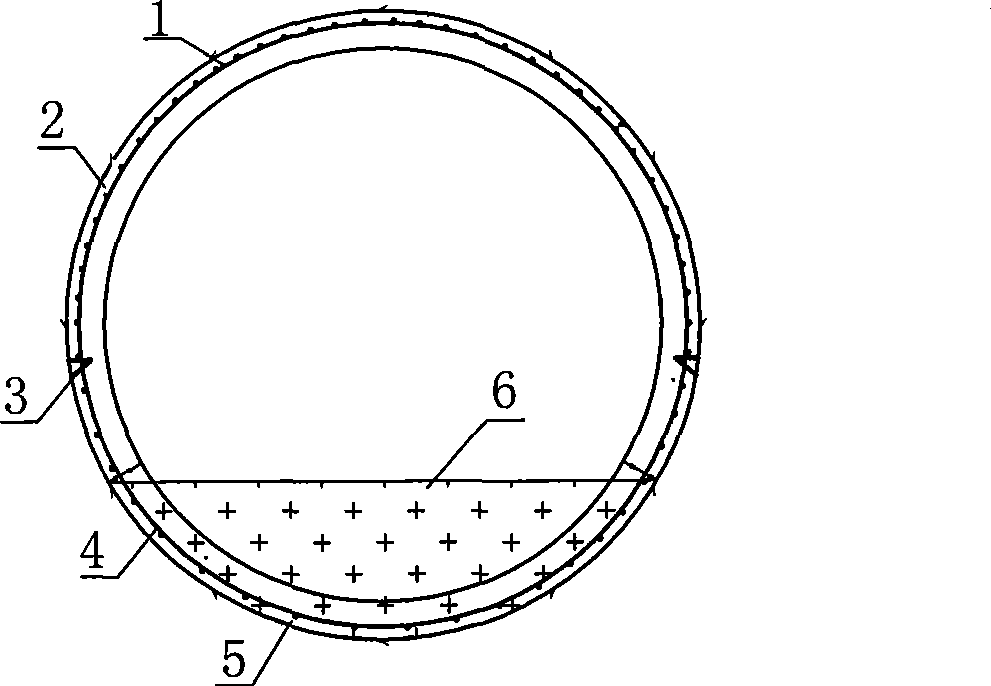

[0010] Such as figure 1 , figure 2 Shown, the construction steps of the present invention are as follows:

[0011] 1. Install side wall top arch reinforcement

[0012] Utilize the floor gravel road 6 that has been formed during the excavation, and install the side wall top arch reinforcing bar 1 in sections. Small hole diameters can directly use gravel roads to install steel bars; for large hole diameters, steel bars can be installed by setting up a small traffic-accessible operating platform on gravel roads. The top arch reinforcement of the side wall is not affected by the slag cleaning of the bottom plate, and can be staggered with the bottom slag cleaning at the same time, or the top arch side wall reinforcement can be installed on multiple working surfaces at the same time;

[0013] When installing the side wall top arch reinforcement, since the reinforcement has no bottom support, it is necessary to drill holes and bury the bottom support 3 of the side wall reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com