Microlens array

A microlens array and microlens technology, applied in the field of microlens arrays, can solve problems such as misalignment, failure of the microlens array mechanism, and decrease in uniformity of the surface to be illuminated 13, so as to prevent failure, improve light uniformity, and improve uniformity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described clearly and completely:

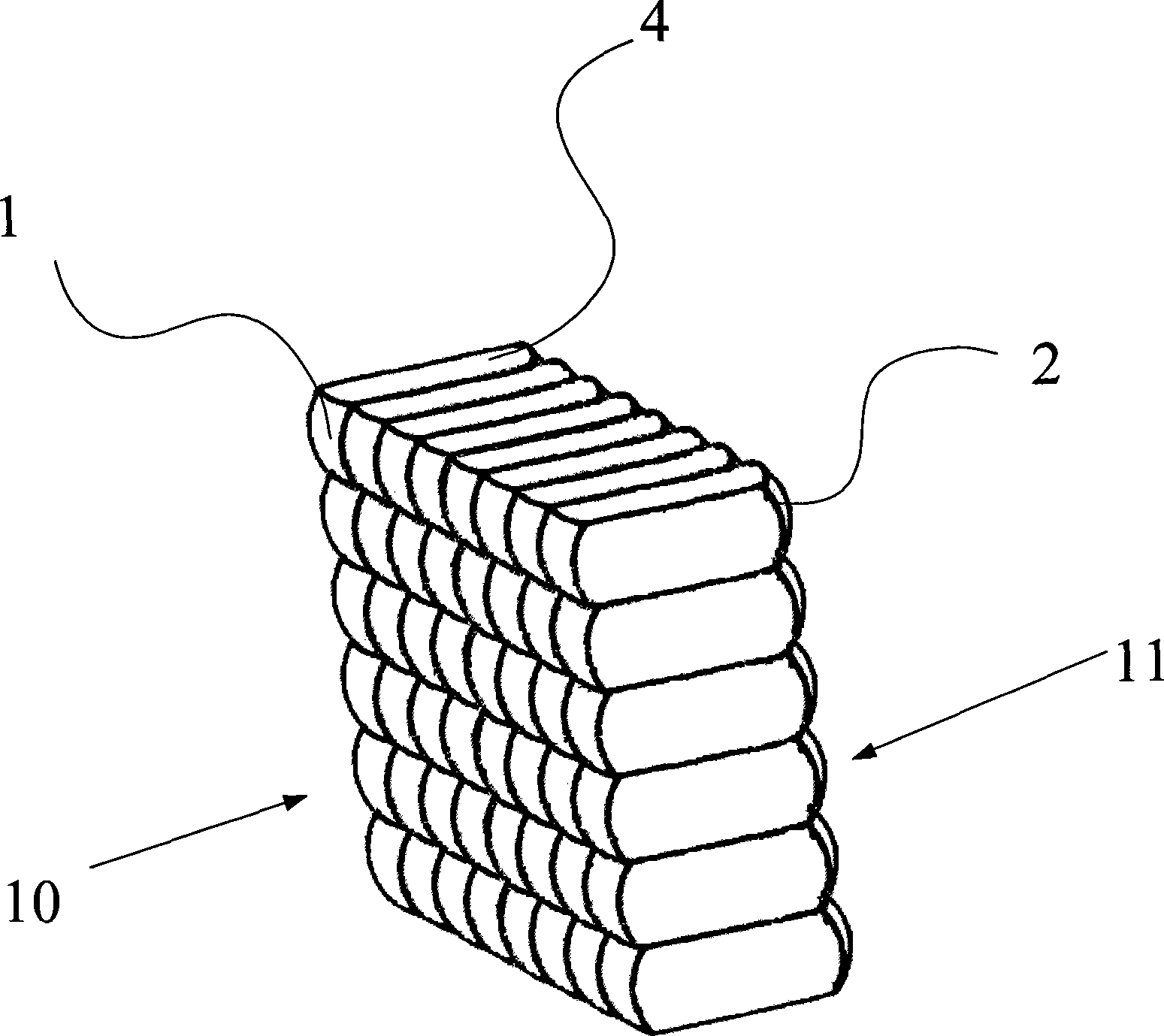

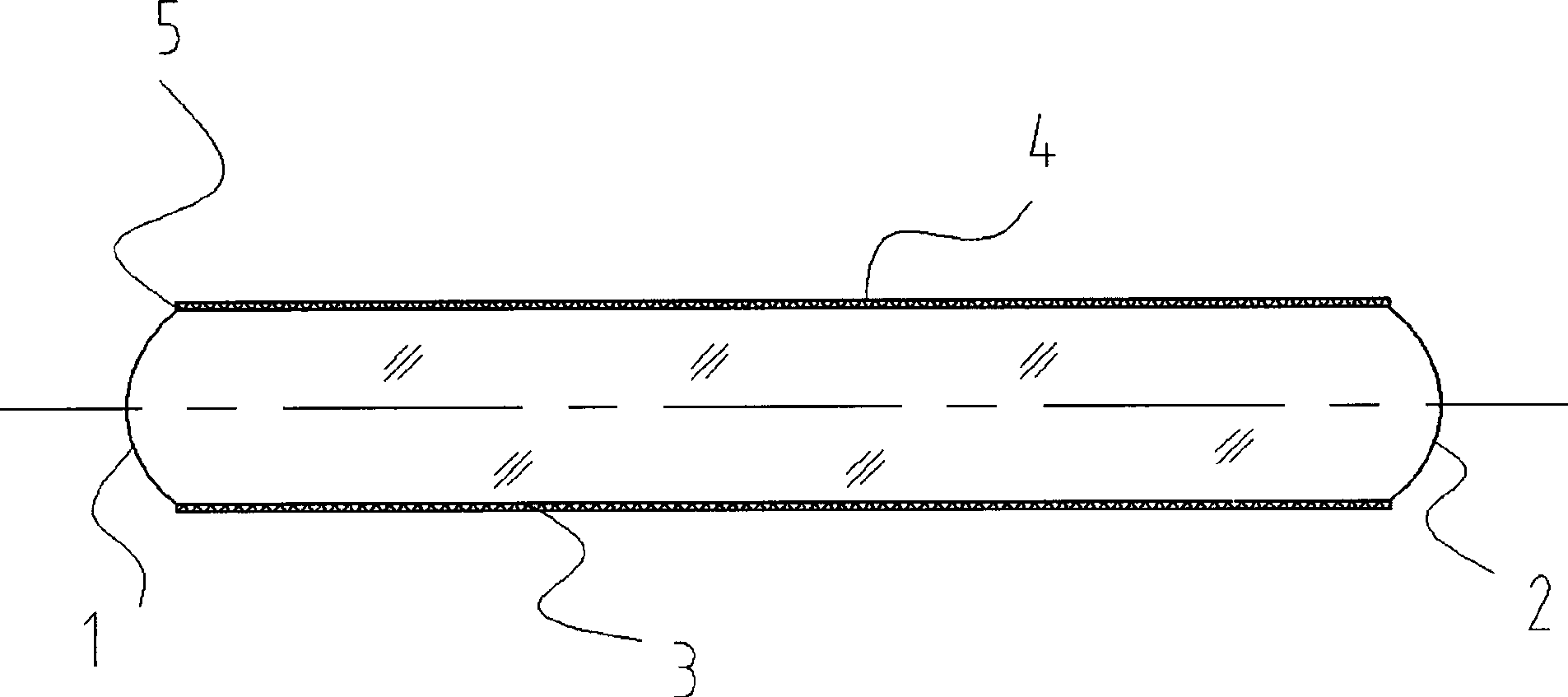

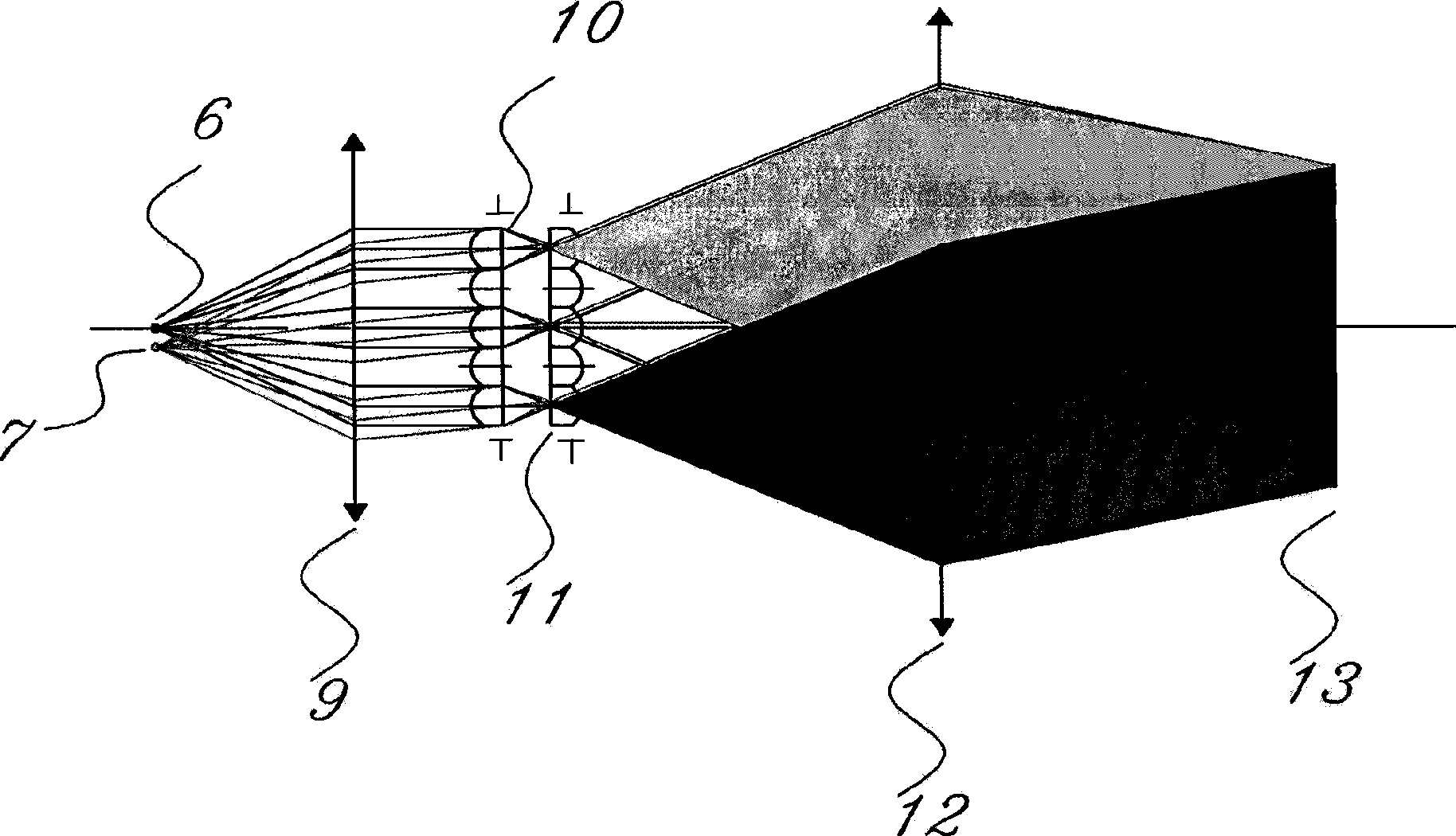

[0024] see figure 1 with figure 2 : figure 1 It is an external view of the microlens array of the present invention. figure 2 It is a sectional view of a microlens unit in the microlens array of the present invention. The microlens array includes at least two microlens units arranged in contact, and the microlens units are surrounded by a front working end surface 1, a rear working end surface 2 and side surfaces. In this embodiment, a microlens array with 6 rows and 8 columns is composed of 48 microlens units. see image 3 , the front working end surface 1 forms a first-level microlens array 10 , and the rear working end surface 2 forms a second-level microlens array 11 . The microlens unit is a rod. The cross-section of the rod-shaped body (that is, the aperture of the microlens unit) is polygonal or circular. In this embodiment, the cross section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com