Fiber composite power cable

A power cable and optical fiber composite technology, which is applied in the direction of power cables, insulated cables, communication cables, etc., can solve problems such as optical transmission loss, and achieve the effect of preventing optical transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

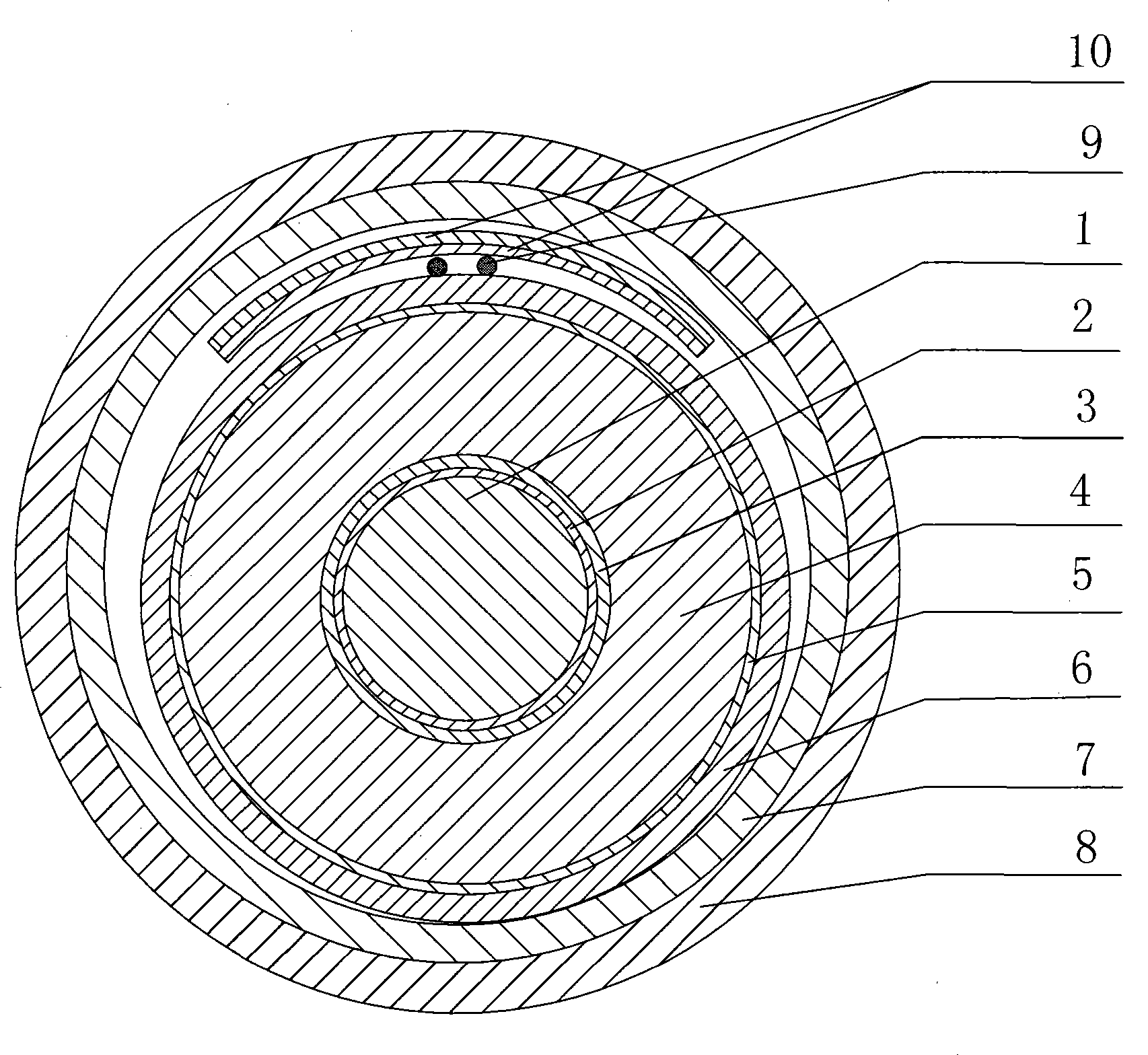

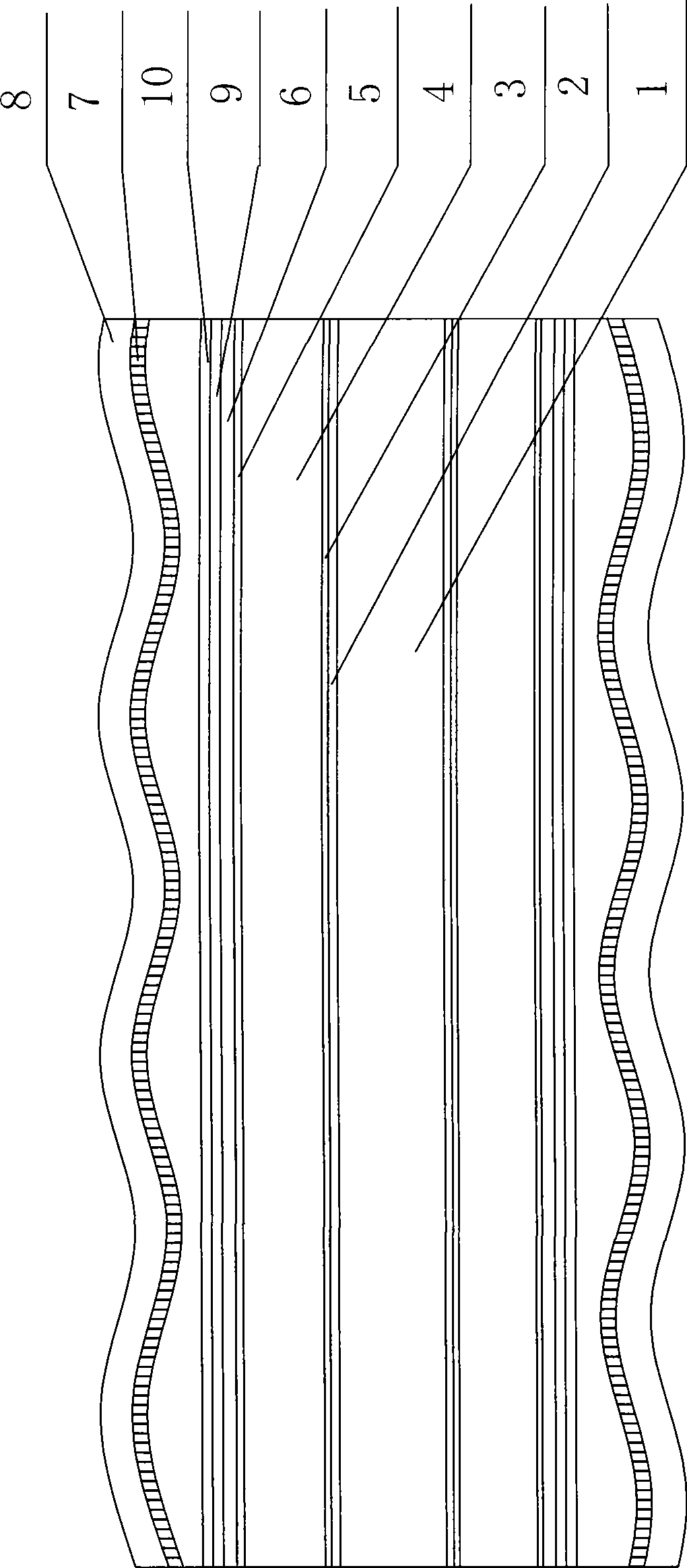

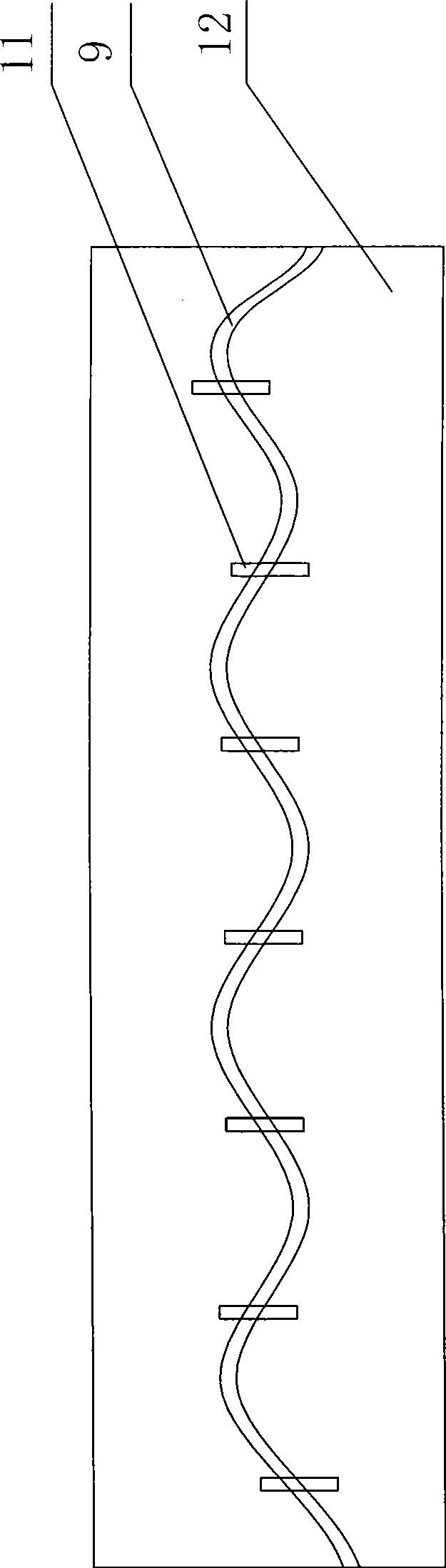

[0048] like Figure 1-Figure 3 As shown, in the optical fiber composite power cable of the present invention, the optical fiber is located between the cable core 12 and the sheath, and the optical fiber is placed on the cable core 12 in a serpentine shape along the length of the cable. The sheath includes a plastic sheath and a metal sheath, and a metal sheath formed in a spiral shape using aluminum or steel will be described below. The metal cable core 12 includes a cable conductor 1, a conductor semiconductive tape 2 covering the periphery of the cable conductor 1, an extruded semiconductive shielding layer 3 covering the periphery of the conductor semiconductive tape 2, and an extruded semiconductive shield covering the outer periphery of the conductor. XLPE (cross-linked polyethylene) insulating layer 4 on the periphery of layer 3, extruded insulating shielding layer 5 covering the periphery of XLPE (cross-linked polyethylene) insulating layer 4, and longitudinal water-blo...

Embodiment 2

[0072] The difference from Example 1 is:

[0073] like Figure 7 As shown, the shape of the metal sheath 7 in this embodiment can also be corrugated.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap