Rolling mill and method for controlling a rolling mill

A technology of rolling equipment and rolling stands, applied in metal rolling, tension/pressure control, braking/tightening devices, etc., to achieve the effect of improving the introduction of tension, uniform tension, and improving controllability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

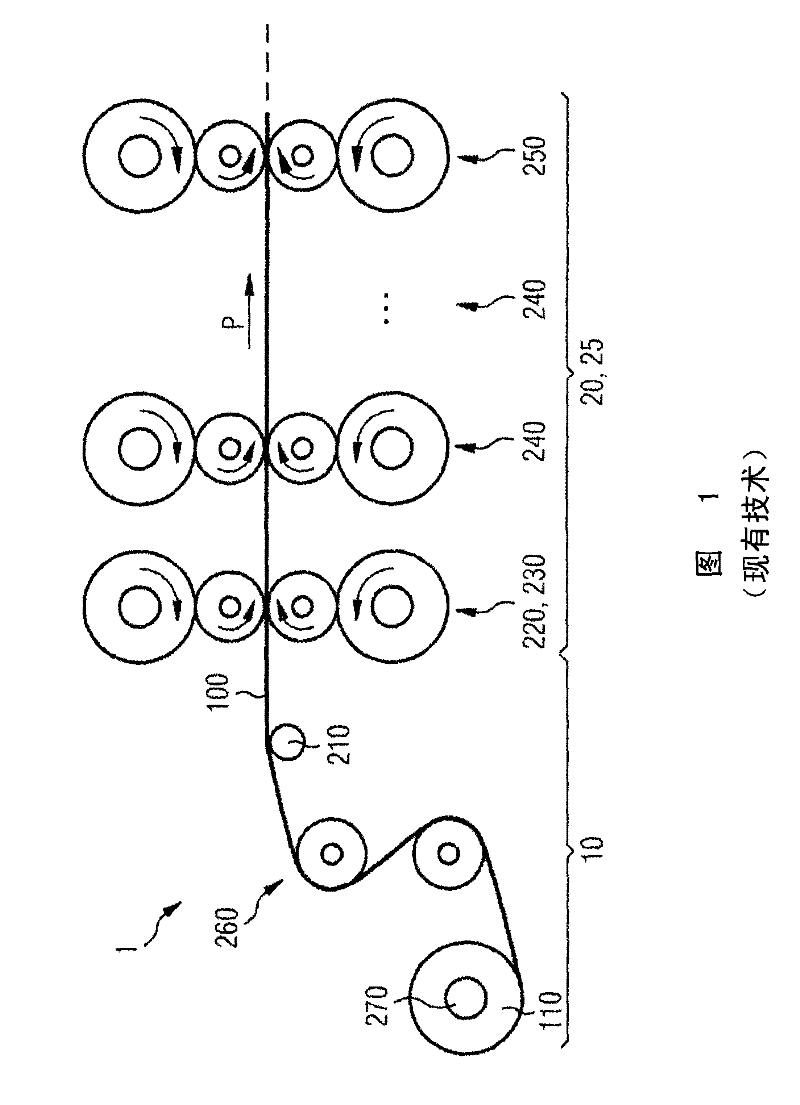

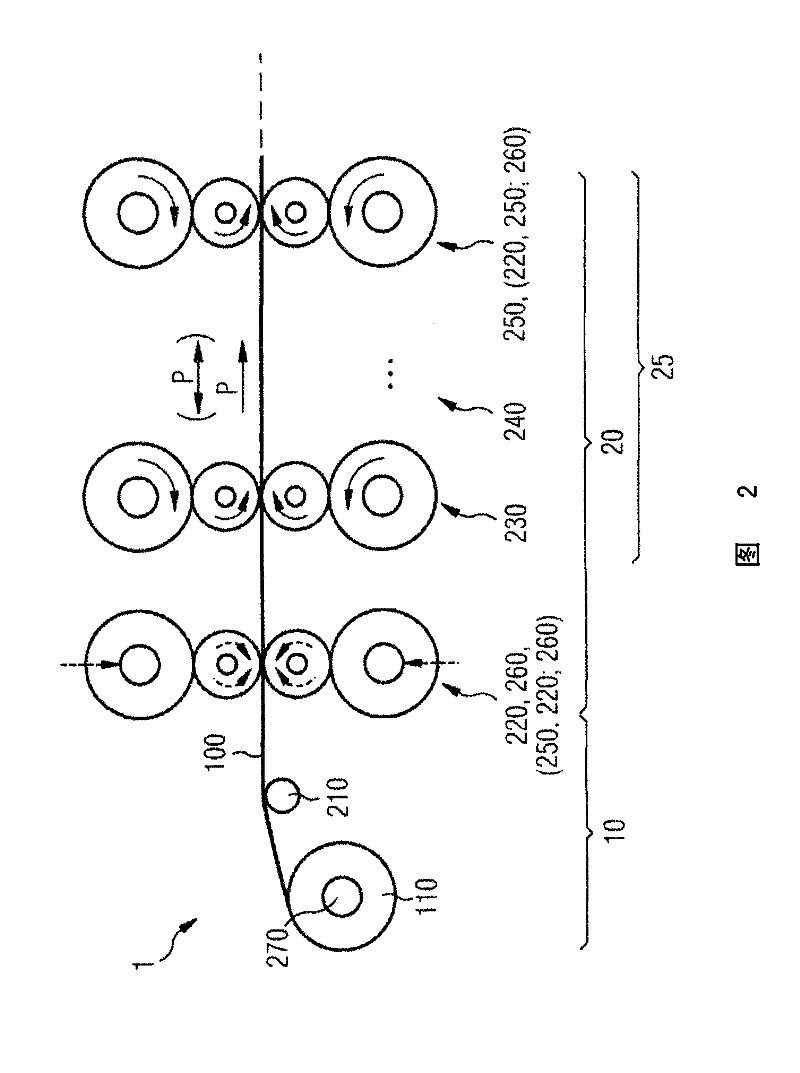

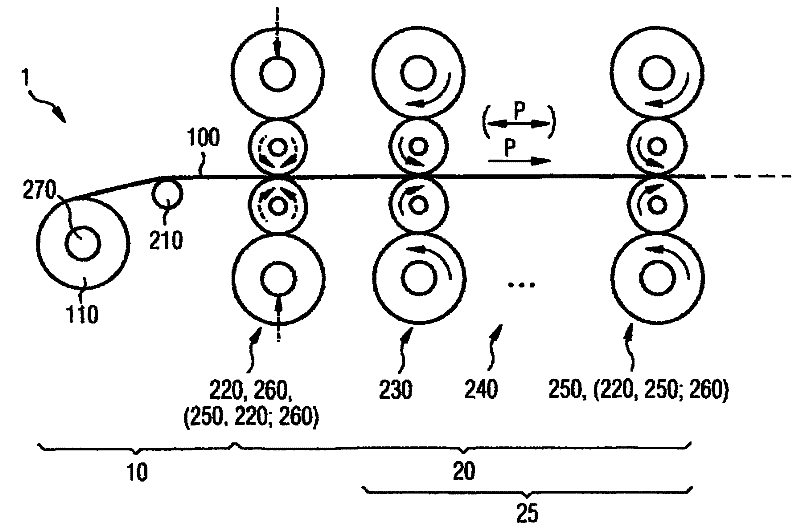

[0026] The following exemplary embodiment relates to a tandem cold strip rolling plant with a metal strip introduction section 10 constructed according to the invention and a tandem rolling train 20 constructed according to the invention. In particular, the tandem rolling train 20 is driven or controlled differently from the prior art, which affects the strip introduction section 10 of the tandem cold strip rolling installation 1 . That is, the package 260 ( FIG. 1 ) having the function of increasing the tension of the strip is not required inside the strip introduction section 10 . However, the invention is not restricted to a tandem cold strip rolling plant 1 , but rather relates to a tandem mill train 20 in general. The tandem rolling train 20 here is a rolling stand arrangement which consists of at least two rolling stands 220 , 230 , 240 , 250 connected in series, preferably directly in series, in the production direction P of the metal strip 100 . That is, the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com