Hydroformylation process

A hydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, organic chemistry, carbon monoxide reaction preparation, etc., can solve problems such as adverse economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of diphosphine ligand

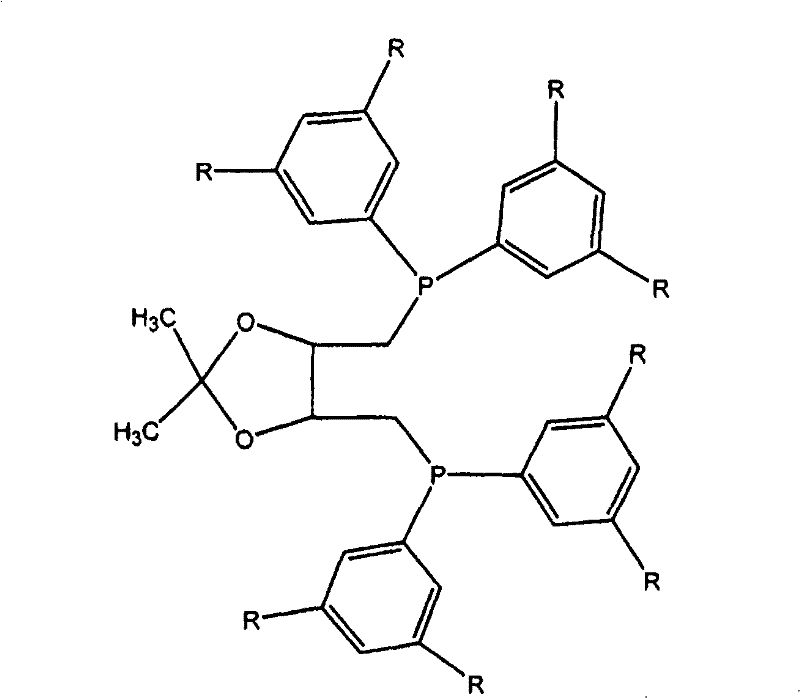

[0026] Diphosphine ligands of the general formula below were prepared as described below.

[0027]

[0028] A solution of 2,2-dimethyl-4,5-bis[(tosyloxymethyl)methyl]-1,3-dioxolane in dry / degassed THF under argon (1 equivalent, 1.73g, 3.7×10 -3A molar amount of dioxolane in 50 mL THF) was added dropwise to a solution of an appropriate amount of lithium diarylphosphine (see formula above) in dry / degassed THF (2.3 equivalents in 100 mL THF). The mixture was heated at reflux for 2 hours, then cooled, and the solvent was removed under reduced pressure. The remaining solid was redissolved in dichloromethane, filtered through a bed of silica, and the solvent was removed under reduced pressure to give 2,3-O-isopropylidene-2,3-dihydroxy-1,4- Bis(diarylphosphino)butane.

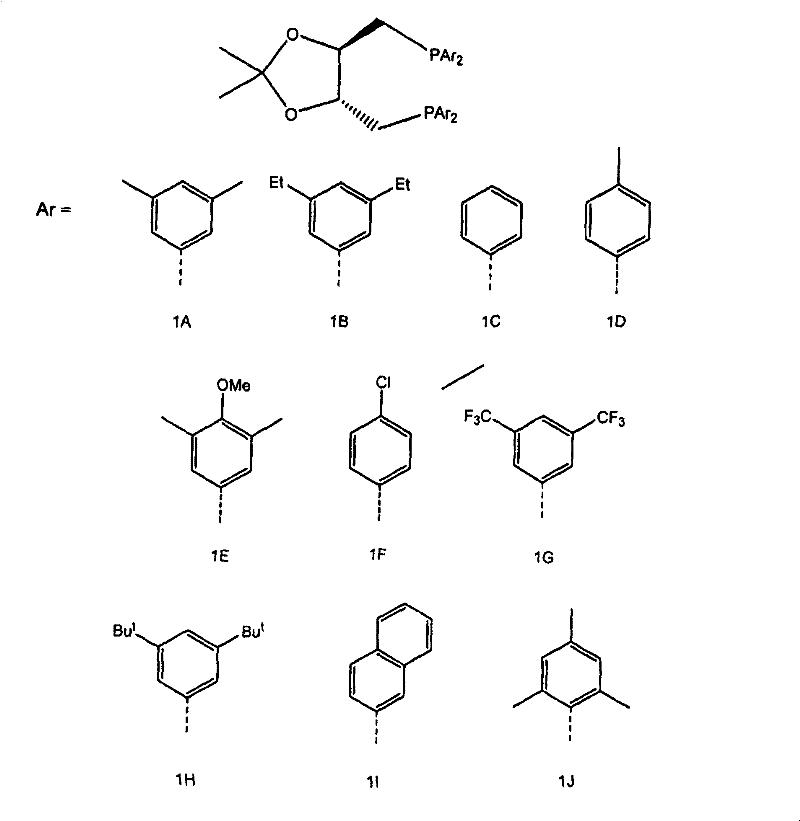

[0029] Diphosphine 1A: 2,3-O-isopropylidene-2,3-dihydroxy-1,4-bis[bis(3,5-dimethylphenyl)phosphino]butane.

[0030] Diphosphine 1B: 2,3-O-isopropylidene...

Embodiment 2

[0039] Example 2: Hydroformylation using a diphosphine ligand

[0040] Diphosphine ligands 1A-1J were used to hydroformylate allyl alcohol according to the following procedure:

[0041] The desired diphosphine (2 equivalents or 8.6×10 -5 mol) in dry degassed toluene (15 g) was added to [Rh(CO) in a 100 mL Parr autoclave 2 (acac)] (1 equivalent or 4.3×10 -5 Moore). Use 1:1 CO / H 2 The solution was rinsed three times with the CO / H 2 The mixture was pressurized to 180 psig. The autoclave was then heated to 65 °C with stirring, allyl alcohol (3.5 mL) was injected, and the CO / H 2 Mixture The autoclave was pressurized to 200 psig. The autoclave was maintained at a constant pressure of 200 psig and the reaction was monitored for gas uptake. When there was no further gas uptake, the autoclave was cooled and depressurized. The resulting solution was analyzed by gas chromatography to determine the product of the reaction. This reaction produces HBA, HMPA and C 3 Products (n-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com