Active substance composition on the basis of metallocene polyolefin waxes for producing stabilized, light-resistant plastic materials

A metallocene polyolefin and active material technology, applied in the field of active material composition and light stabilizer, can solve the problems of reduced mechanical properties, uneven distribution of components, low strand strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

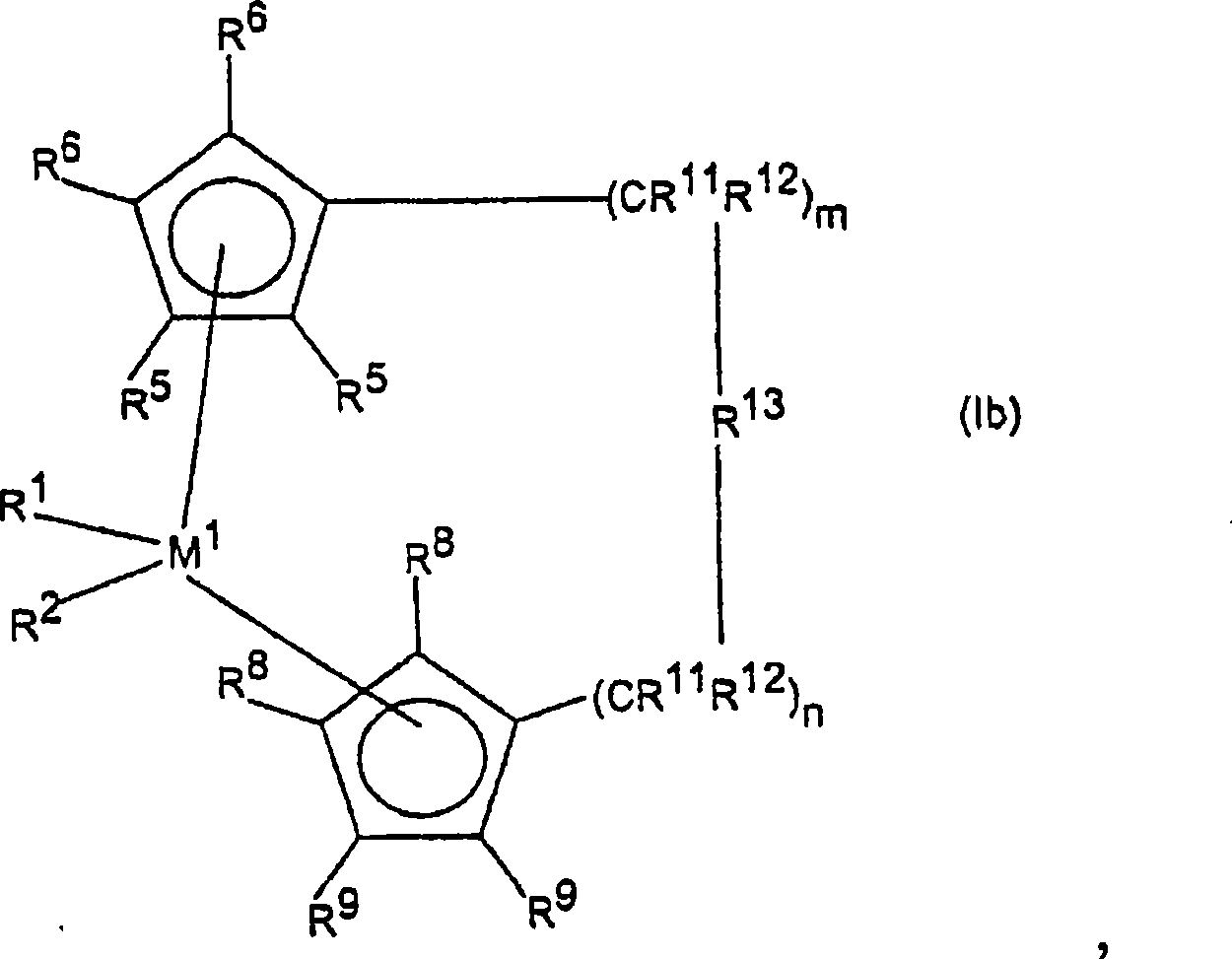

[0120] The metallocene waxes a to d listed in Table 1 used according to the invention were obtained by using the metallocene catalyst dimethylsilylbisindene according to the method given in EP A0 384 264 (General Procedure Examples 1-16) It is prepared by copolymerizing propylene and ethylene with zirconium dichloride. Different softening points and viscosities can be adjusted by changing ethylene feed and polymerization temperature.

[0121] Product properties were determined according to the following methods:

[0122] Dropping point ISO 2176 / / ASTM D 3954(℃)

[0123] Viscosity DIN 53018(mPa·s)

[0124] Density ISO 1183(g / cccm)

[0125] Molar mass determination by means of gel permeation chromatography (GPC)

[0126] Metallocene waxes used

[0127] Metallocene waxes a) Metallocene wax b) Metallocene wax c) Metallocene waxes d) Dropping point (℃) 92 93 102 140 Viscosity at 170°C

(mPa·s) 2900 7900 9800 65

[0128] Properties of no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com