Brushless hand-held tool

A technology for tools and brush hands, which is applied in the field of brushless hand-held tools, can solve the problems of loose and cracked control lines, easy failures, poor contact, etc., and achieve the effect of meeting the requirements of rapid cooling, ensuring normal use, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

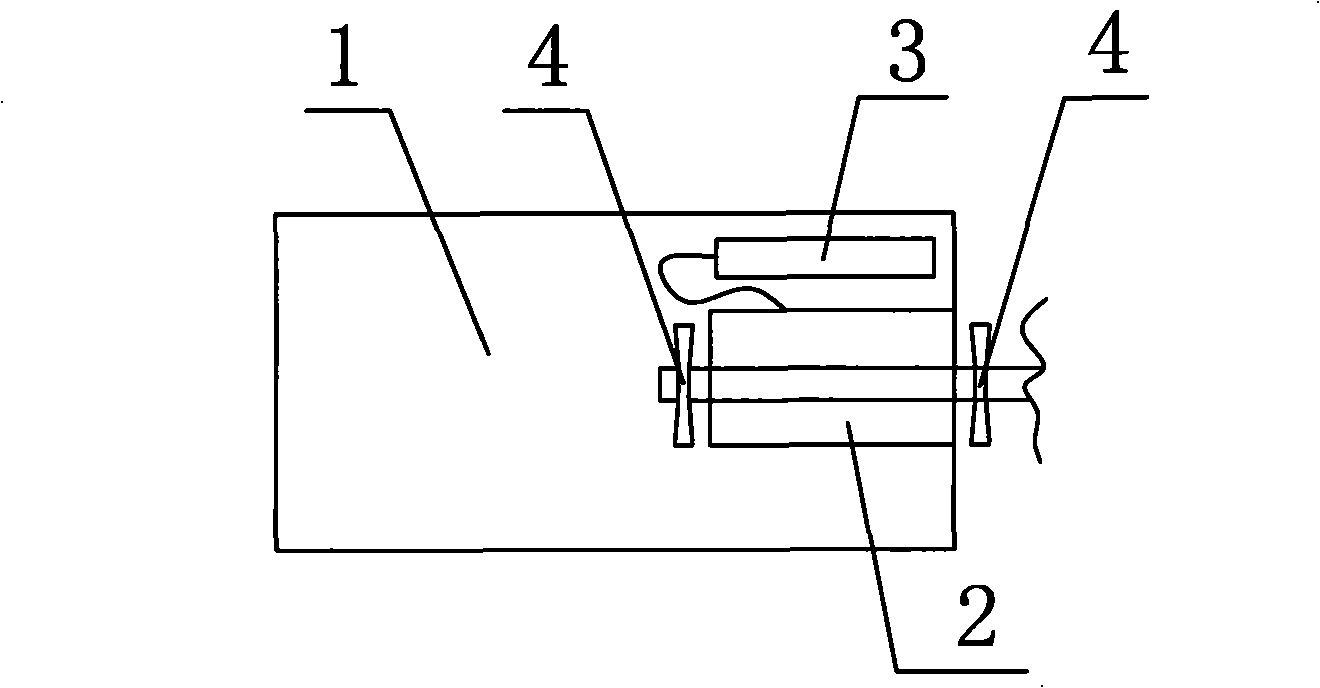

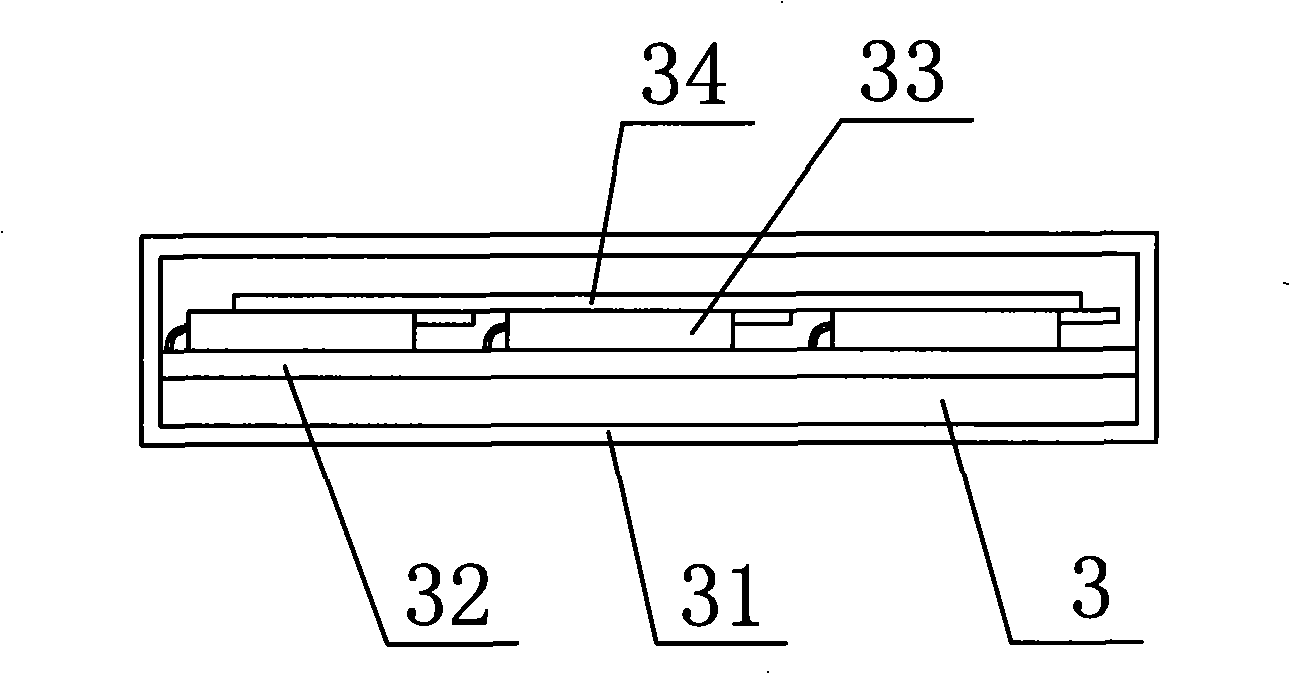

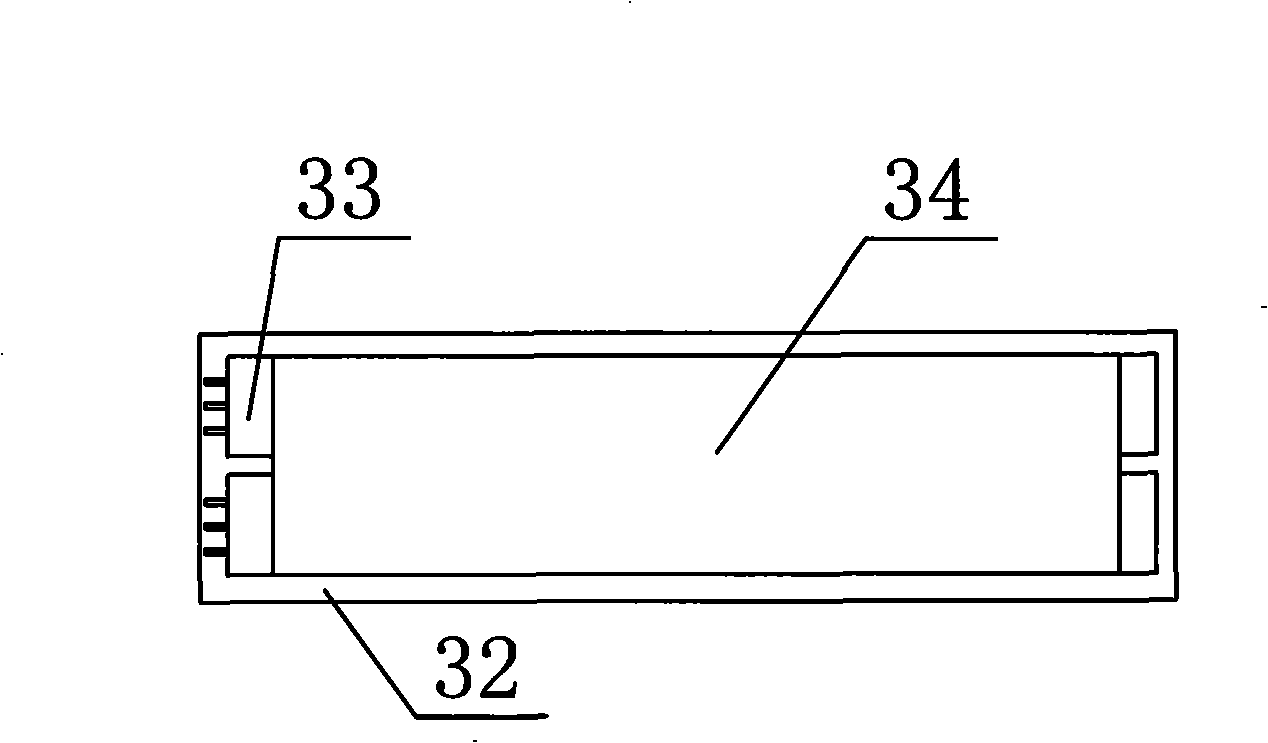

[0017] Such as Figure 1 to Figure 4 , a brushless hand-held tool, including a tool body 1, a brushless motor 2 installed in the tool body 1, a driver 3 connected to the brushless motor 2, and the driver 3 is arranged inside the tool body 1. The driver 3 includes a driver body 31 and a circuit board 32 disposed in the driver body 31 . The circuit board 32 is provided with a plurality of horizontally placed MOS tubes 33 , and a cooling fin 34 is stacked on the MOS tubes 33 . The horizontal setting of the MOS tube 33 reduces the volume of the circuit board 32, and correspondingly reduces the volume of the driver 3, so that the driver 3 can be directly arranged in the tool body 1, preventing the control line between the driver 3 and the brushless motor 2. Poor contact due to loosening and cracking caused by external pulling. The circuit board 32 includes a control chip 321 and a driving unit 322, and the driving unit 322 uses an integrated circuit to drive the chip. The integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com