Material gathering unit

A technology for collecting devices and materials, which is applied in the direction of packaging and binding machine parts, etc., can solve the problems of high manufacturing cost of sprockets and chains, complex structure of material shifting devices, and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

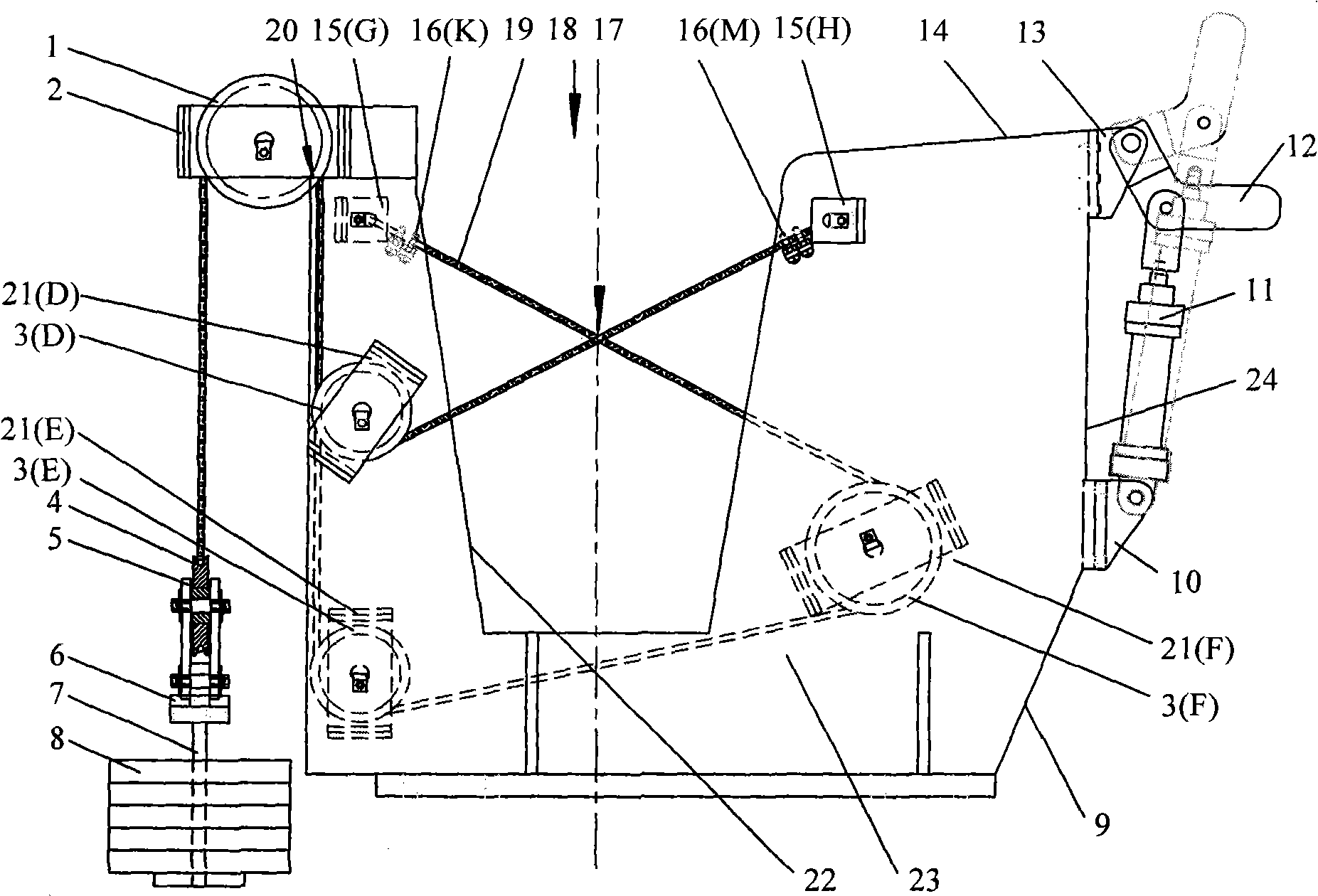

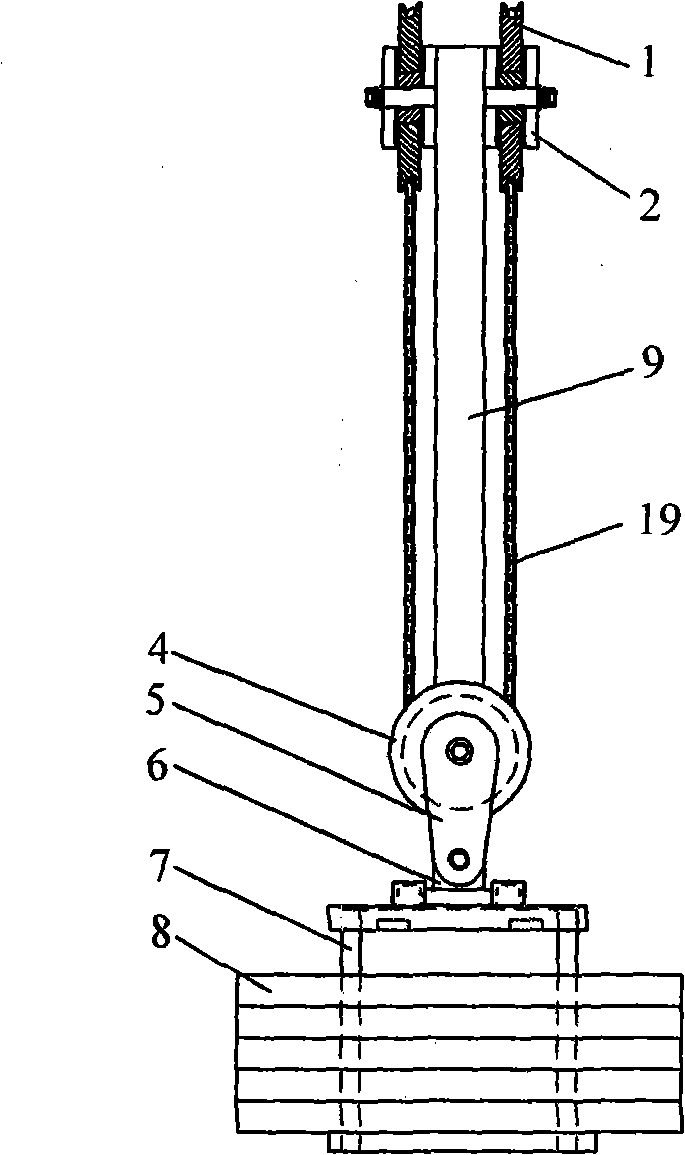

[0024] The specific implementation of the material collection device of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Depend on figure 1 As shown, the material collection device of the present invention includes a material basket 9, a material shifting device and a blanking buffer device arranged on the material basket 9, and a lifting mechanism for controlling the blanking buffer device. in:

[0026] There are one or more material baskets 9, and each material basket 9 has an inverted conical collection opening 18 that runs through the two sides of the entire material basket 9, and the end platform of one wing in the two wings of the collection opening is designed as a collection opening inclined toward the center of the collection opening. Material ramp 14.

[0027] The material shifting device includes an "L"-shaped support arm 12 and a hydraulic cylinder 11, as well as a bracket fixedly installed on the wing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com