Air generating mechanism for pre-network devices for polyamide composite filaments

A polyester-nylon compounding and pre-network technology, which is applied in the direction of pumping device, filament generation, filament/thread forming, etc., can solve the problems of high energy consumption, waste, and unfavorable saving of electric energy in the gas production mechanism, and achieve the goal of reducing equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

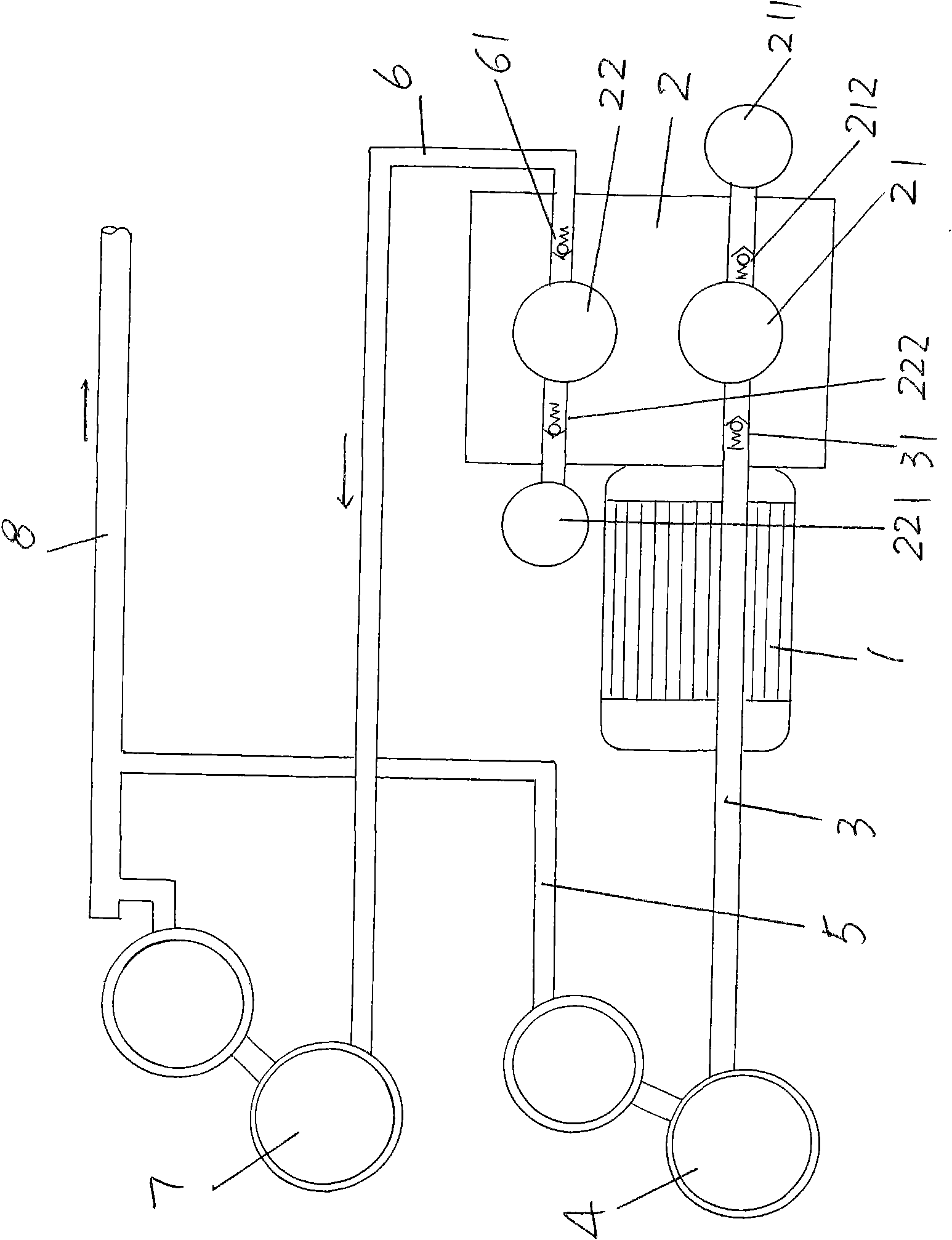

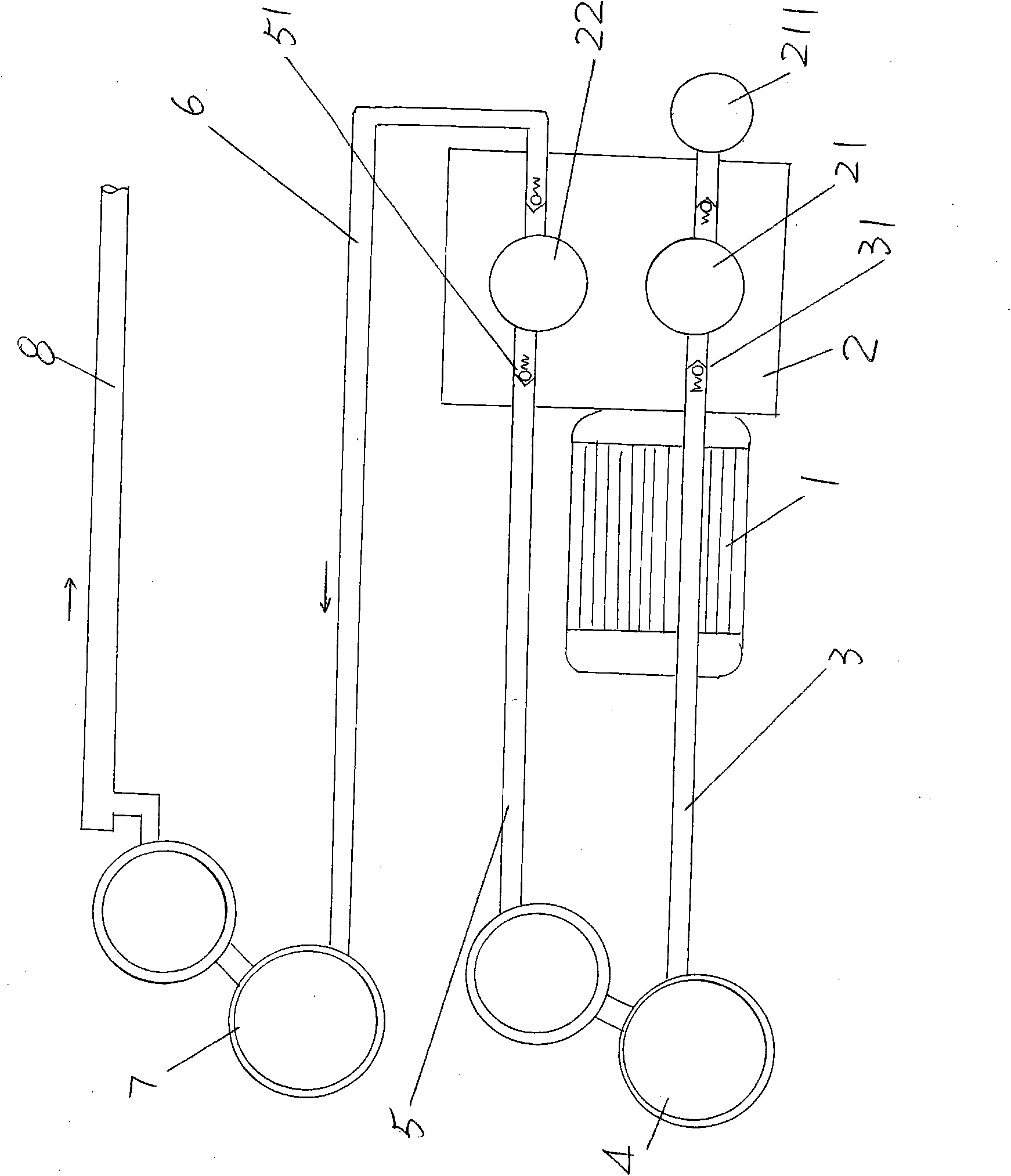

[0010] please see figure 1 , the gas generating mechanism given is essentially a piston air compressor, the motor 1 is matched with the piston compressor 2, the piston compressor 2 has first and second cylinders 21, 22, and the first cylinder 21 is A first air filter element 211 is provided on the air port, and a first intake valve 212 is provided on the channel of the intake port of the first cylinder 21, and the first intake valve 212 is a one-way valve. A second air filter element 221 is provided on the intake port of the second cylinder 22, and a second intake valve 222 is provided on the passage of the intake port of the second cylinder 22, and the second intake valve 222 is a one-way valve. . One end of the first air outlet pipe 3 is connected to the piston compressor 2 and communicated with the first cylinder 21, the passage of the first air outlet pipe 3 is provided with a first air outlet valve 31, the first air outlet pipe 3 The other end is connected to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com