Method for driving solenoid-operated fuel injector in diesel

A fuel injector, fuel injection technology, applied in the direction of fuel injection device, fuel injection control, internal combustion piston engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

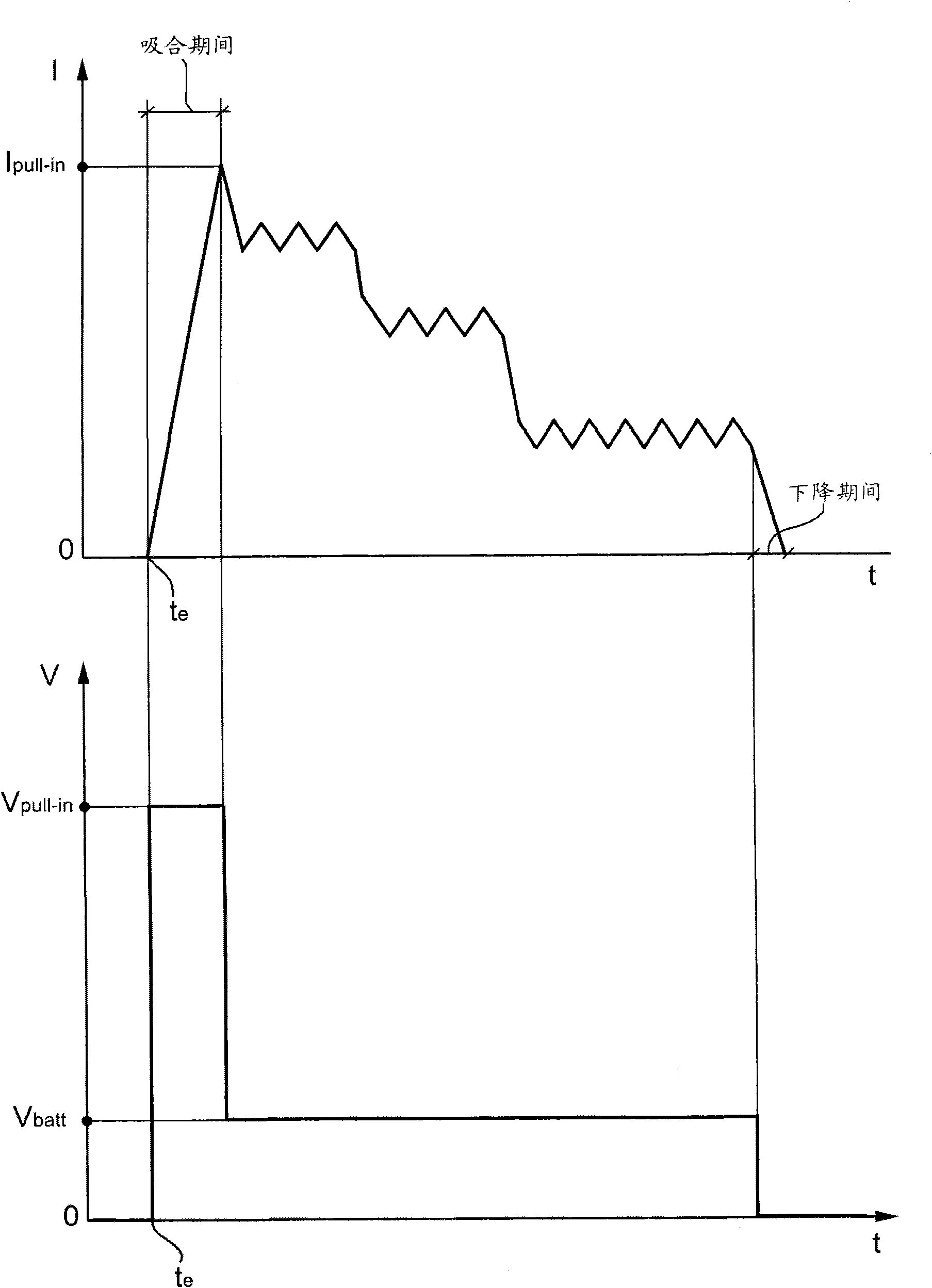

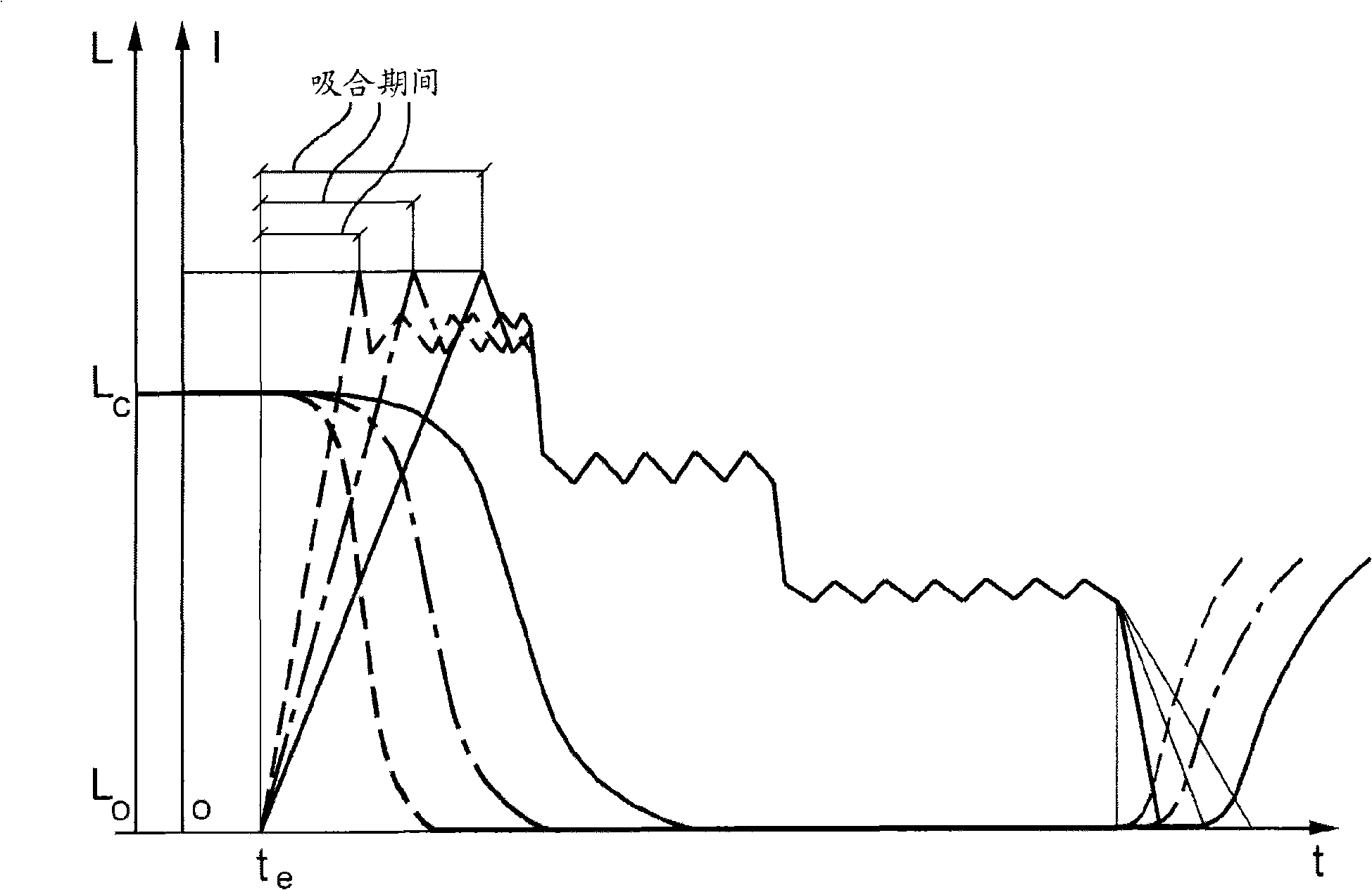

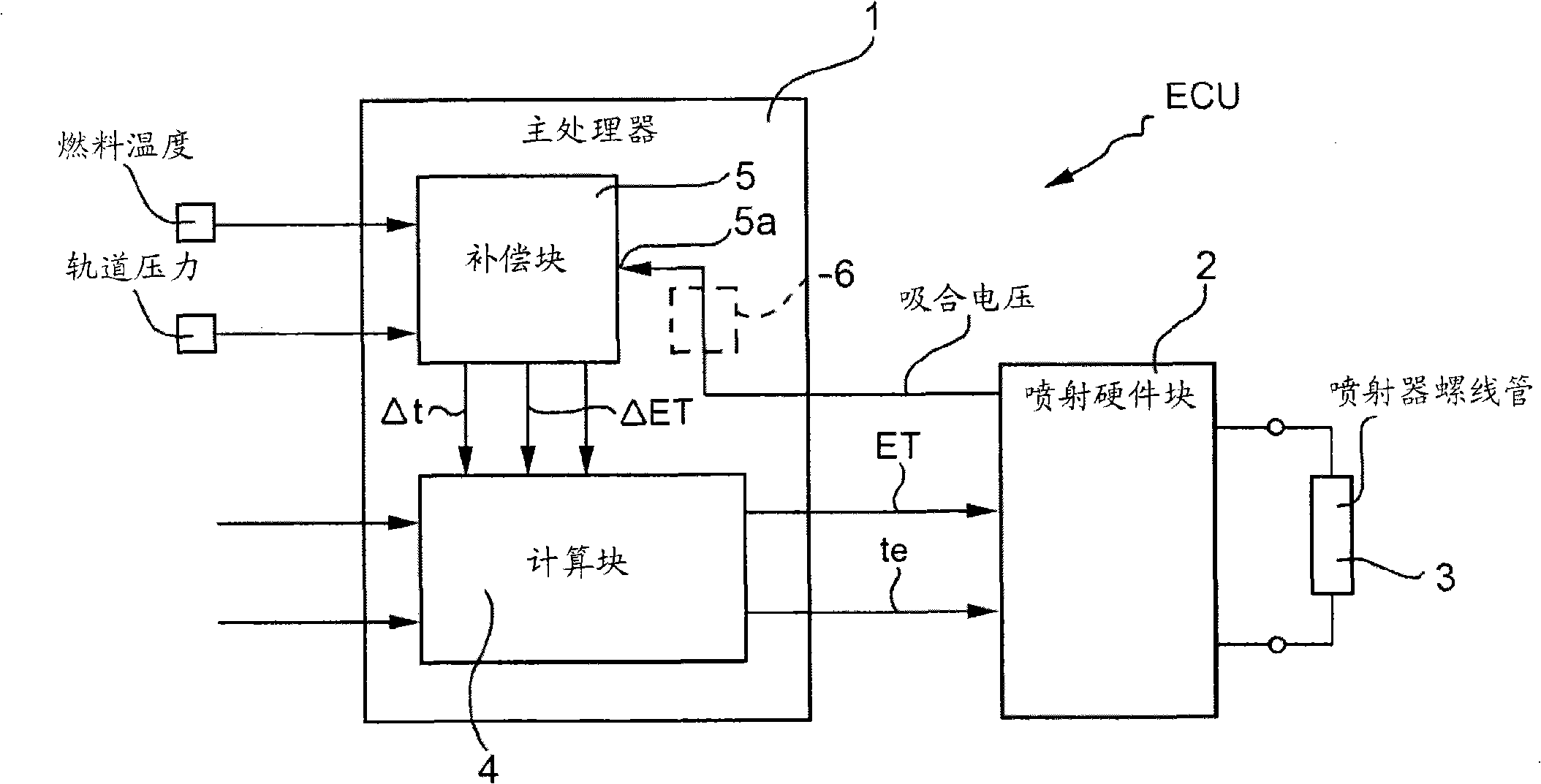

[0021] In a first embodiment, the method according to the invention is basically based on monitoring the actual value of the pull-in voltage: when said actual value of the voltage is lower than the expected value, i.e. lower than the predetermined nominal value, the injection start time and The solenoid energization time is modified to at least partially compensate for deviations in the actual value of the pull-in voltage from the nominal value. In particular, the injection start time (or corresponding crank angle value) is predicted relative to the nominal injection time by an amount substantially proportional to the decrease in the sensed pull-in voltage, and the solenoid energization time ET is increased relative to its nominal value Basically proportional to the amount of reduction in pull-in voltage.

[0022] In general, the functional relationship between the reduction of the pull-in voltage, the corresponding advance of the injection start time and the increase of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com