Monte Carlo simulation based method for predicting pass percent of pull-in voltages of contactors

A technology of Monte Carlo simulation and pull-in voltage, which is applied to instruments, electrical digital data processing, special data processing applications, etc., can solve the problems of high design and test costs, long design cycle, etc., to reduce test costs and improve reliability The effect of shortening the trial production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

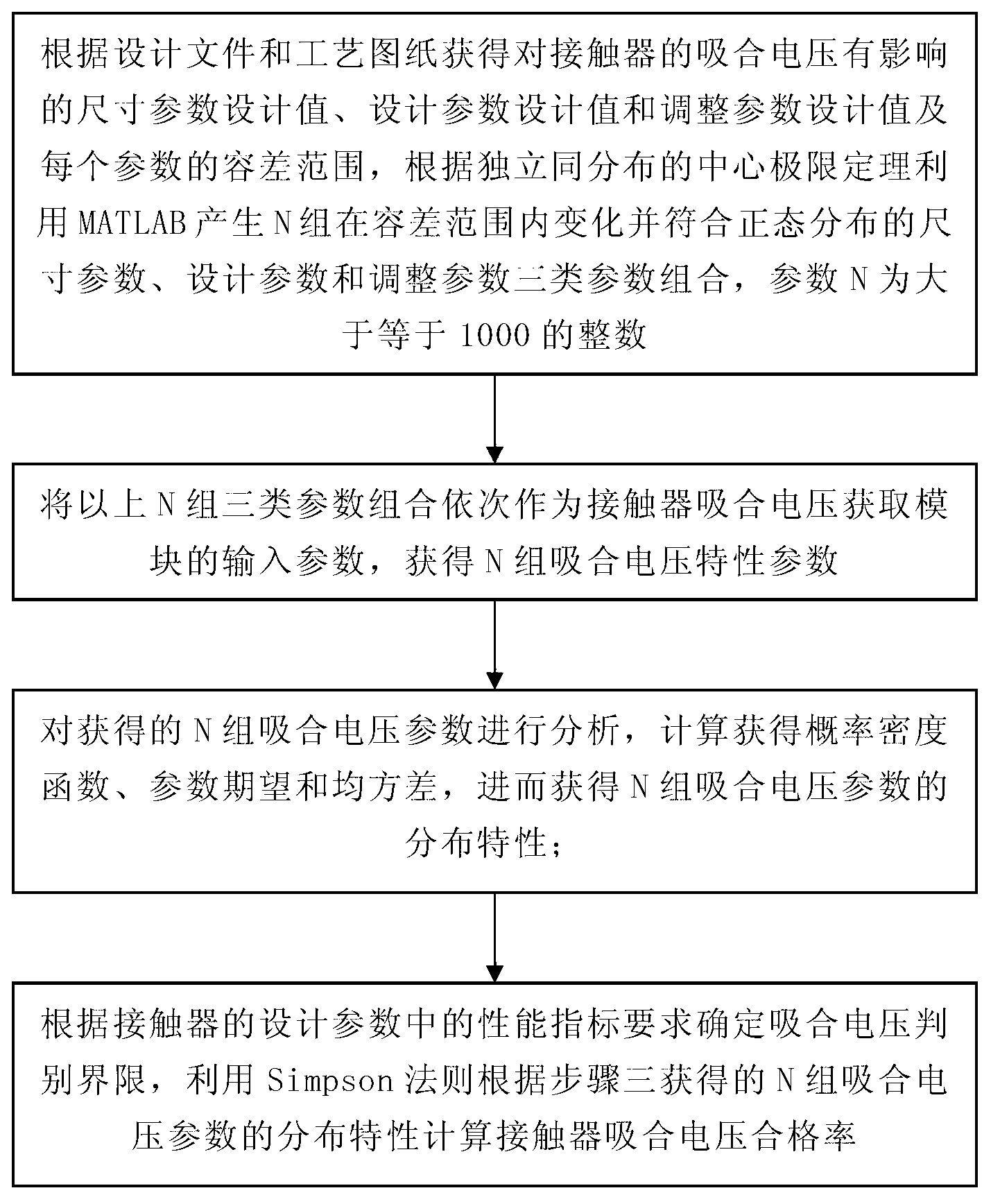

[0041] Specific implementation mode one, see figure 1 This embodiment will be described. A method for predicting the qualification rate of contactor pull-in voltage based on Monte Carlo simulation described in this embodiment, the method includes the following steps:

[0042] Step 1: According to the design documents and process drawings, obtain the design values of size parameters, design values of design parameters, design values of adjustment parameters and the tolerance range of each parameter that affect the pull-in voltage of the contactor. According to the central limit of independent and identical distribution Theorem uses MATLAB to generate N groups of three types of parameter combinations that vary within the tolerance range and conform to the normal distribution: size parameters, design parameters, and adjustment parameters. The parameter N is an integer greater than or equal to 1000;

[0043]Step 2: Use the above N groups of three types of parameter combinat...

specific Embodiment approach 2

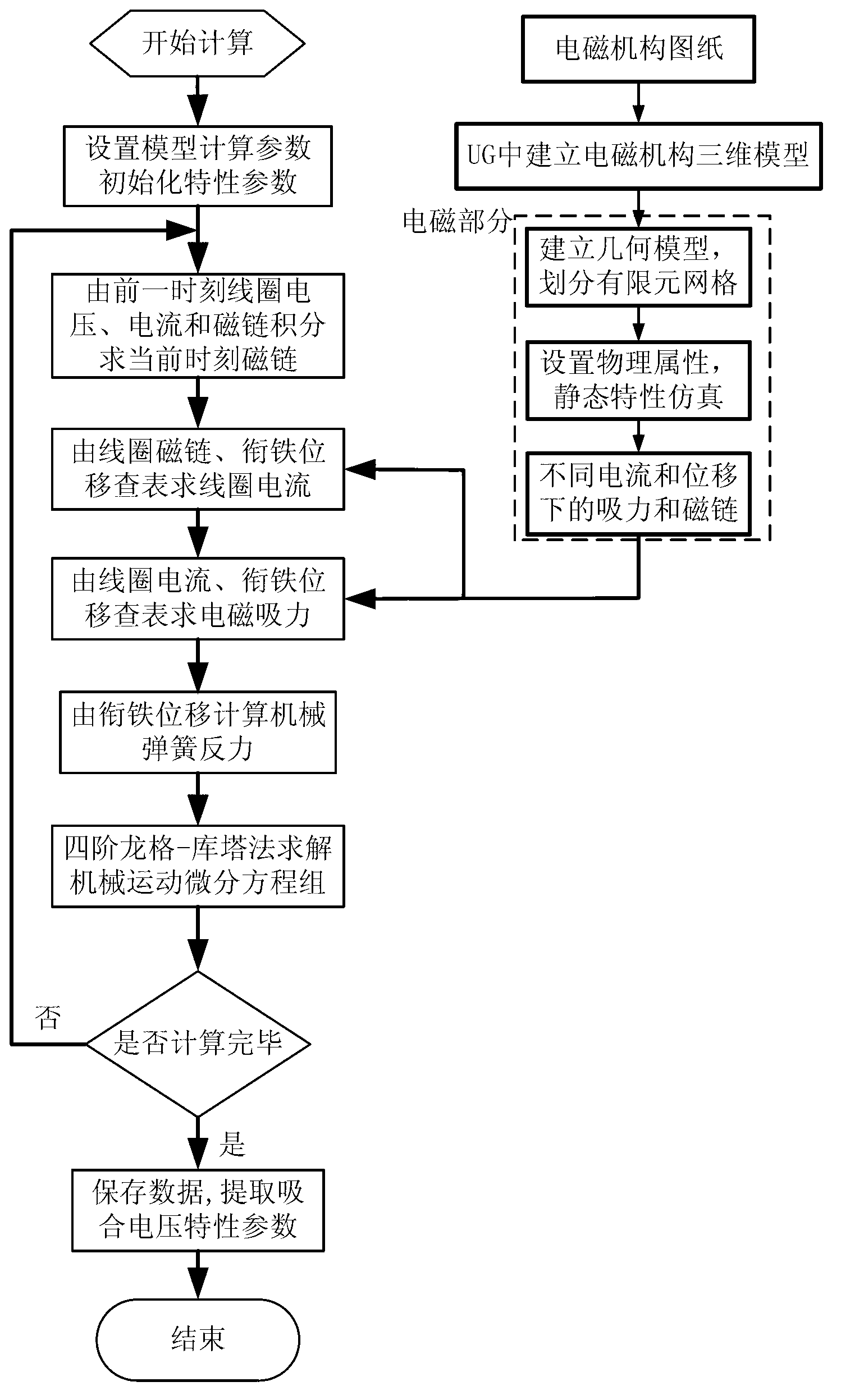

[0048] Specific implementation mode two, see figure 2 This embodiment will be described. The difference between this embodiment and the Monte Carlo simulation-based contactor pull-in voltage qualification rate prediction method described in the first embodiment is that the contactor pull-in voltage acquisition module is implemented by software technology, and the work of this module The process includes the following steps:

[0049] Step A, setting the calculation parameters of the contactor model and initializing the characteristic parameters;

[0050] Step B, calculating the flux linkage at the current moment from the integral of the coil voltage, current and flux linkage at the previous moment;

[0051] Step C, obtaining the coil current from the coil flux linkage and armature displacement look-up table;

[0052] Step D, the coil current and armature displacement obtained in step C are checked in the comparison table to obtain the electromagnetic attraction force;

[0...

specific Embodiment approach 3

[0064] Specific Embodiment 3. The difference between this embodiment and the Monte Carlo simulation-based method for predicting the qualified rate of contactor pull-in voltage described in Embodiment 2 is that the comparison table is the coil flux linkage of the contactor with respect to the coil A two-dimensional table of current and armature displacement, which is obtained by the following steps:

[0065] Step H, establish a three-dimensional model of the electromagnetic mechanism in the UG software according to the design drawing of the electromagnetic mechanism of the contactor;

[0066] Step 1, through the software finite element software FLUX, according to the three-dimensional model of the electromagnetic mechanism, calculate the coil current, armature displacement, electromagnetic attraction force and flux linkage of multiple groups of contactors;

[0067] Step J, according to step I, obtain the coil current, armature displacement, electromagnetic attraction force and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com