Full-automatic polypeptide synthetic instrument

A fully automatic technology for peptide synthesis, applied in the fields of peptides, peptide preparation methods, chemical instruments and methods, etc., can solve the problems of operator injury, incomplete synthesis, affecting synthesis quality, etc., to reduce the generation of waste liquid , shorten the trial production cycle, the effect of reasonable interface design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

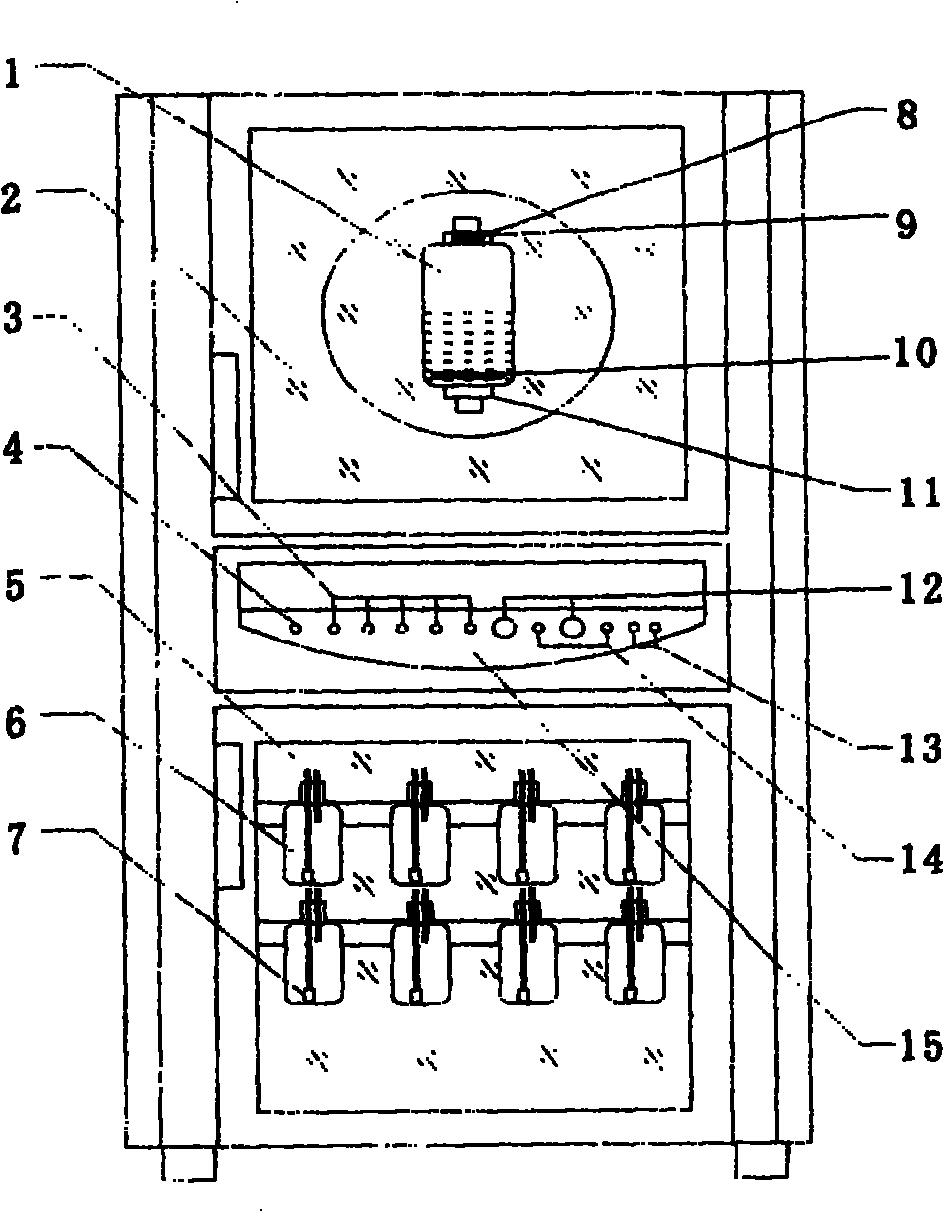

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

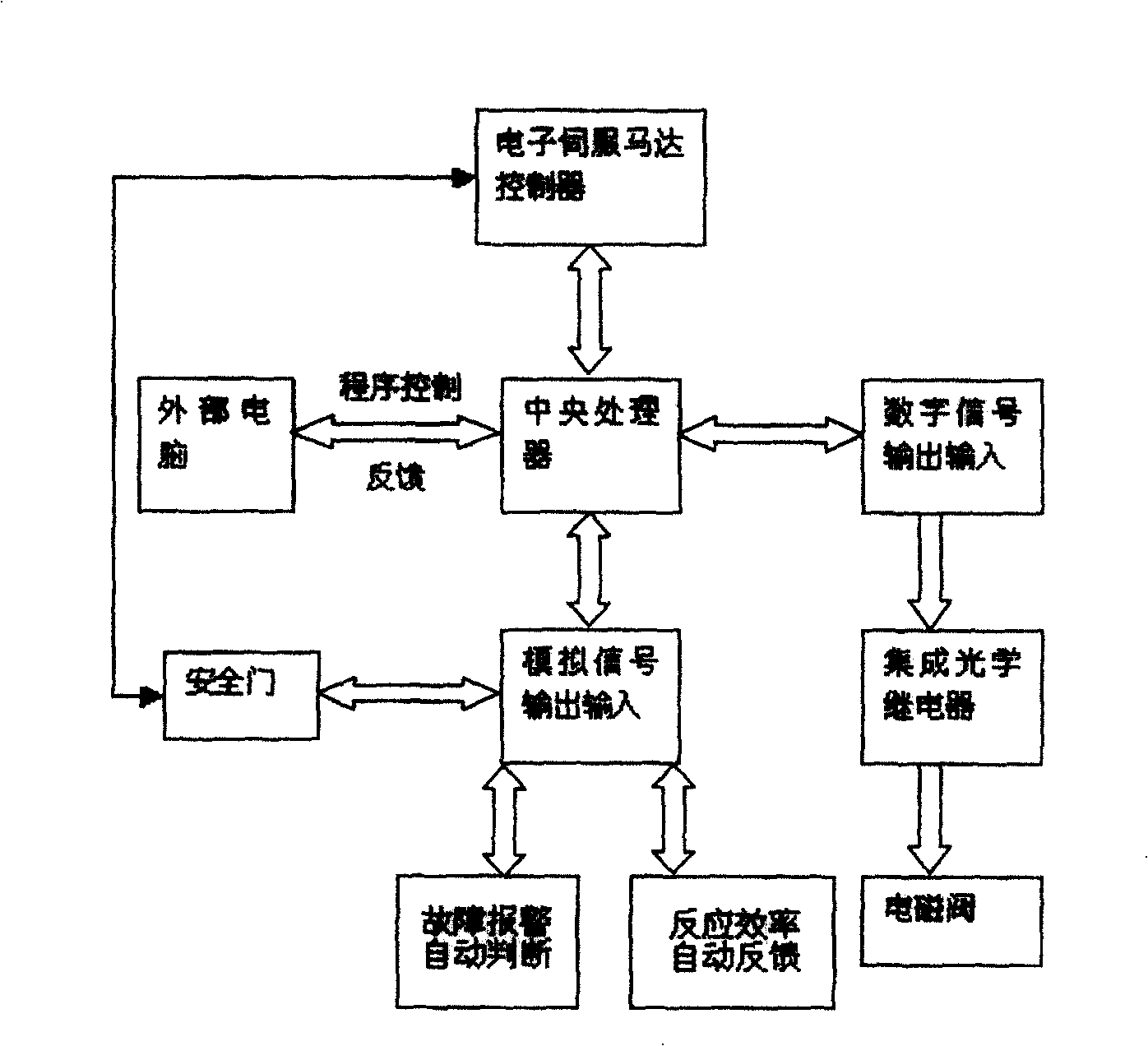

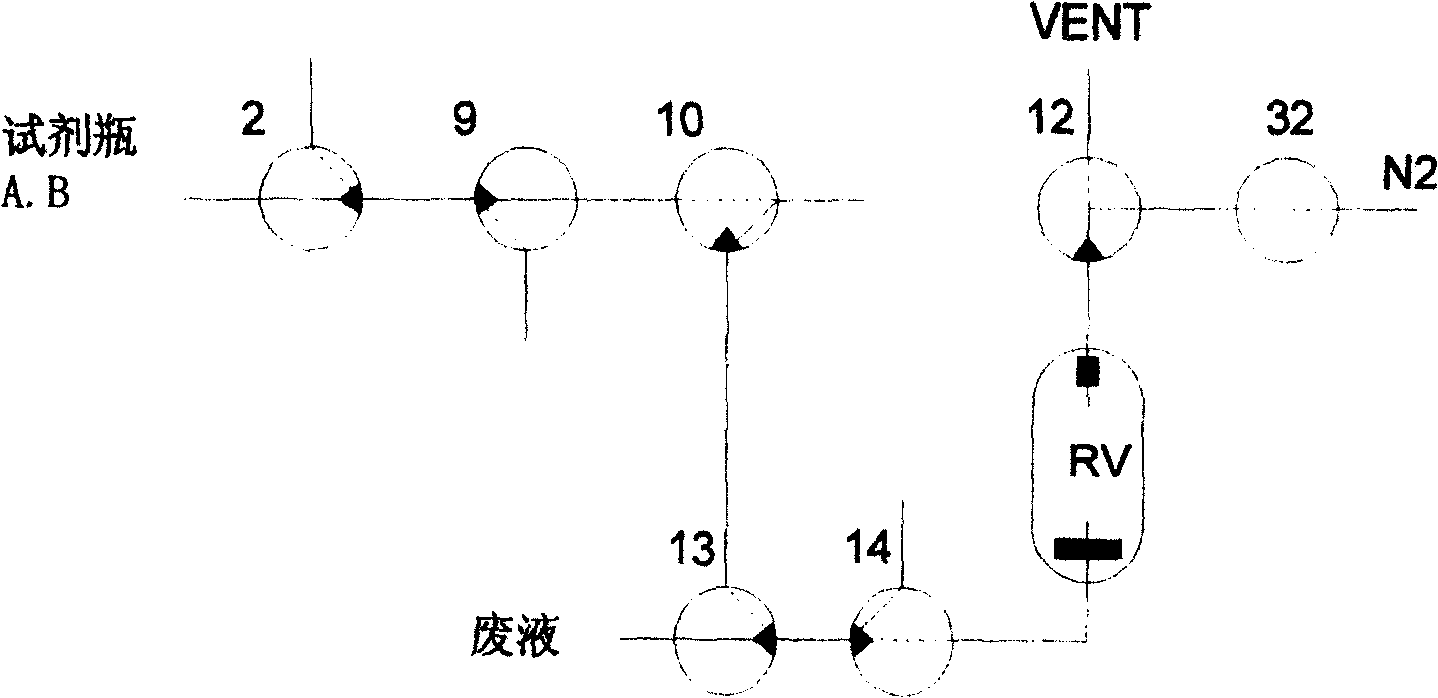

[0028] Depend on image 3 , Figure 4 It can be seen that the present invention includes: a central processing unit system 18, a GMP software operating system, a liquid control system, a gas control system, a raw material input system, a reactor system, a stepless speed regulation stirring system, and a personal safety guarantee system. system, a reaction efficiency automatic feedback system, a fault alarm system, and a solution circulation system;

[0029] Described central processor system 18 comprises: central processor, digital signal input / output circuit, analog signal input / output circuit, electronic servo motor controller 22 and external computer; Described central processor controls digital signal input / output respectively Output circuit, analog signal input / output circuit, electronic servo motor controller 22, and accept the instructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com