Method for evaluating repetitive frequency laser damage resistance of optical thin film

A technology of repetition rate and laser damage, which is applied in the direction of scattering characteristic measurement, optical test defect/defect, scientific instruments, etc., can solve the problems of higher precision requirements of online detection equipment, cumbersome data processing methods, increased time cost, etc., to achieve test The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

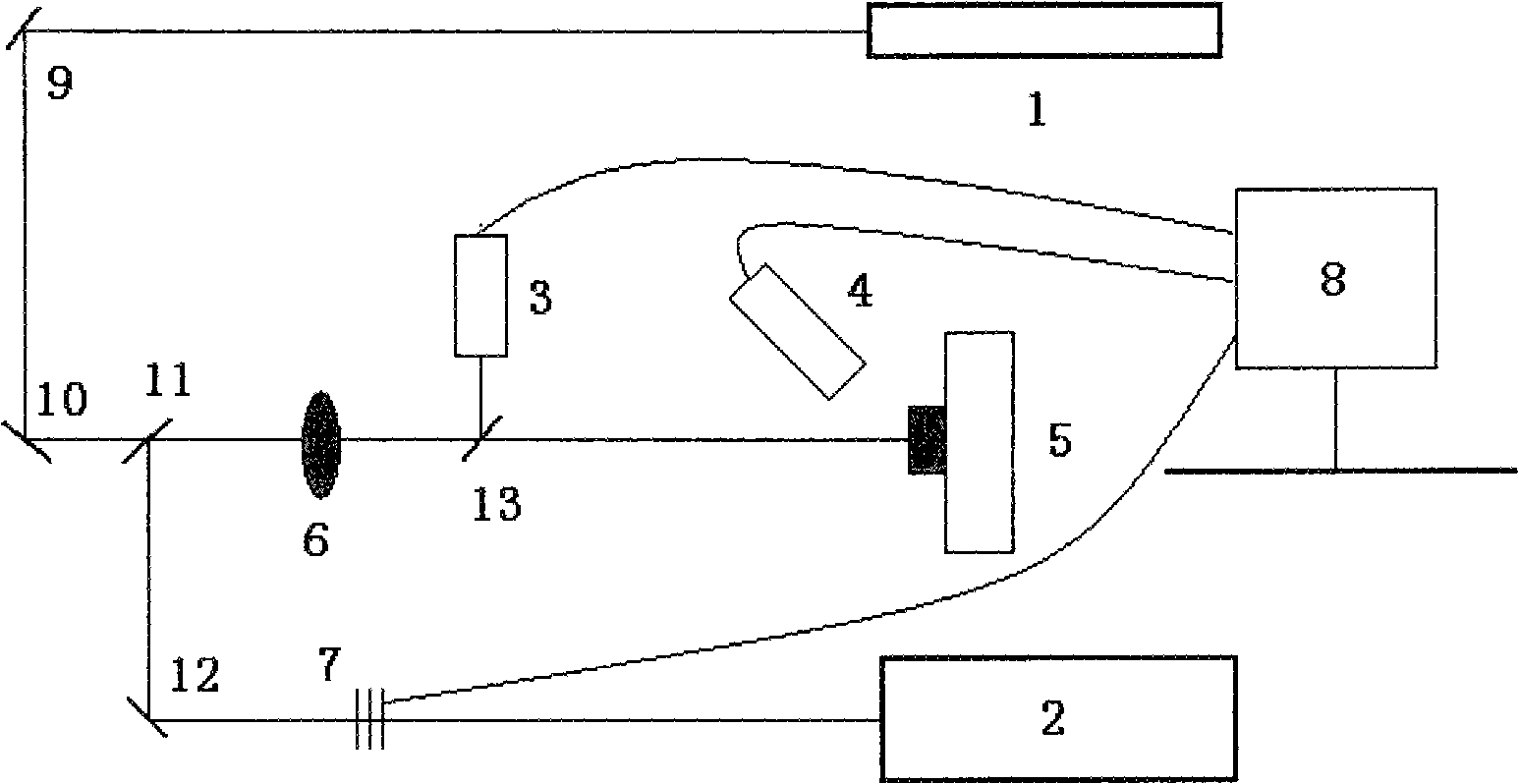

[0025] see first figure 1 , figure 1 It is the schematic diagram of the testing device of optical thin film anti-repetition frequency laser damage characteristic of the present invention, among the figure: 1 is He-Ne laser device, 2 is 1064nm repetition frequency solid pulse laser (repetition frequency is 5Hz), 3 is laser power meter, 4 is Microscopic detector, 5 is a two-dimensional moving sample stage, 6 is a focusing lens, 7 is a laser energy regulator, 8 is a control computer, 9 and 10 are 632.8nm mirrors, 11 is high-transparency@632.8nm / high-reflection@ 1064nm lens, 12 is 1064nm reflective mirror, 13 is 1064nm low reflective mirror. according to figure 1 A test device for the anti-repetition frequency laser damage characteristics of the optical thin film of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com