Brushless electric motor rotor

A brushless motor and motor rotor technology, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/pattern/structure, etc. , to achieve the effect of reducing production costs and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

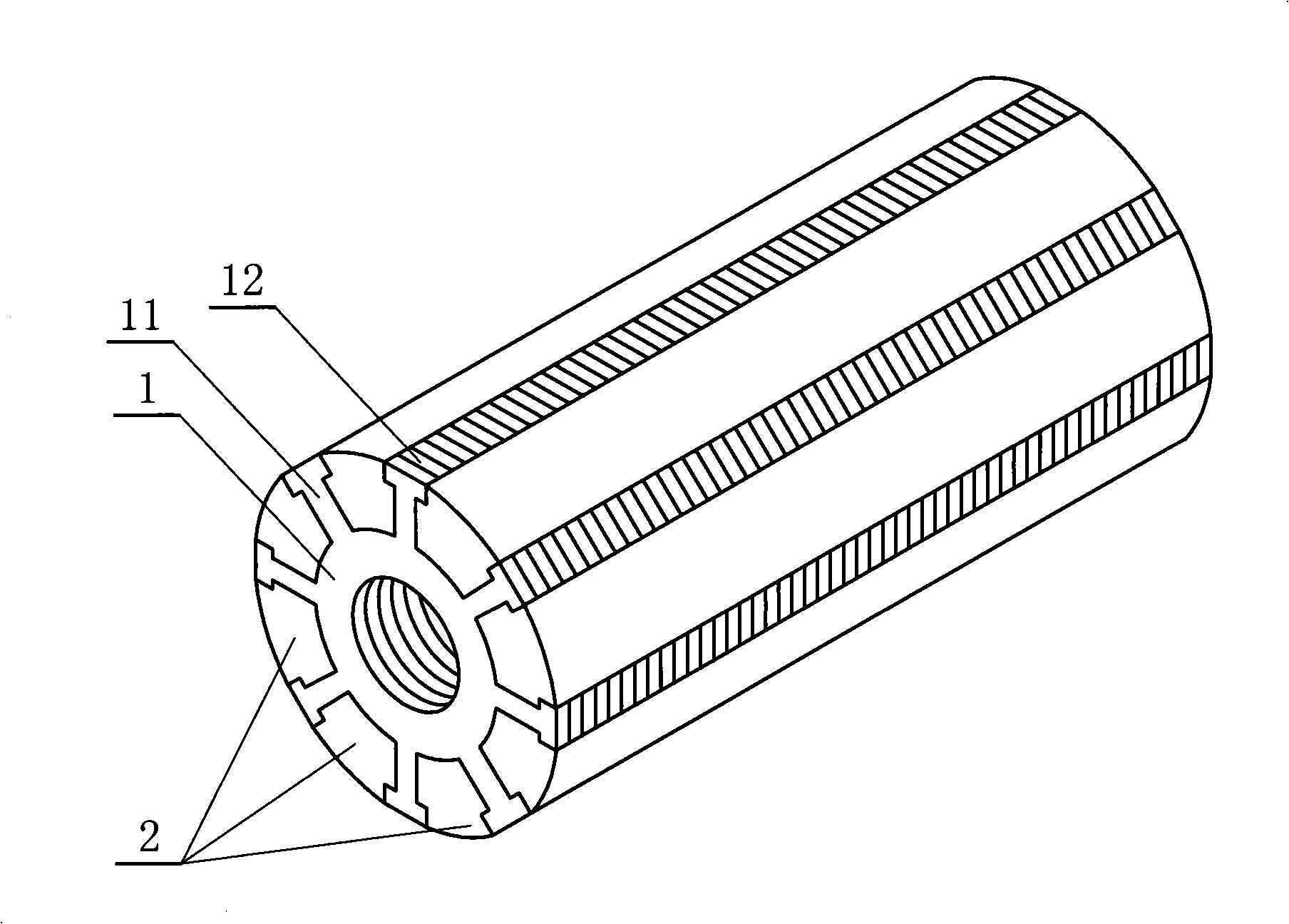

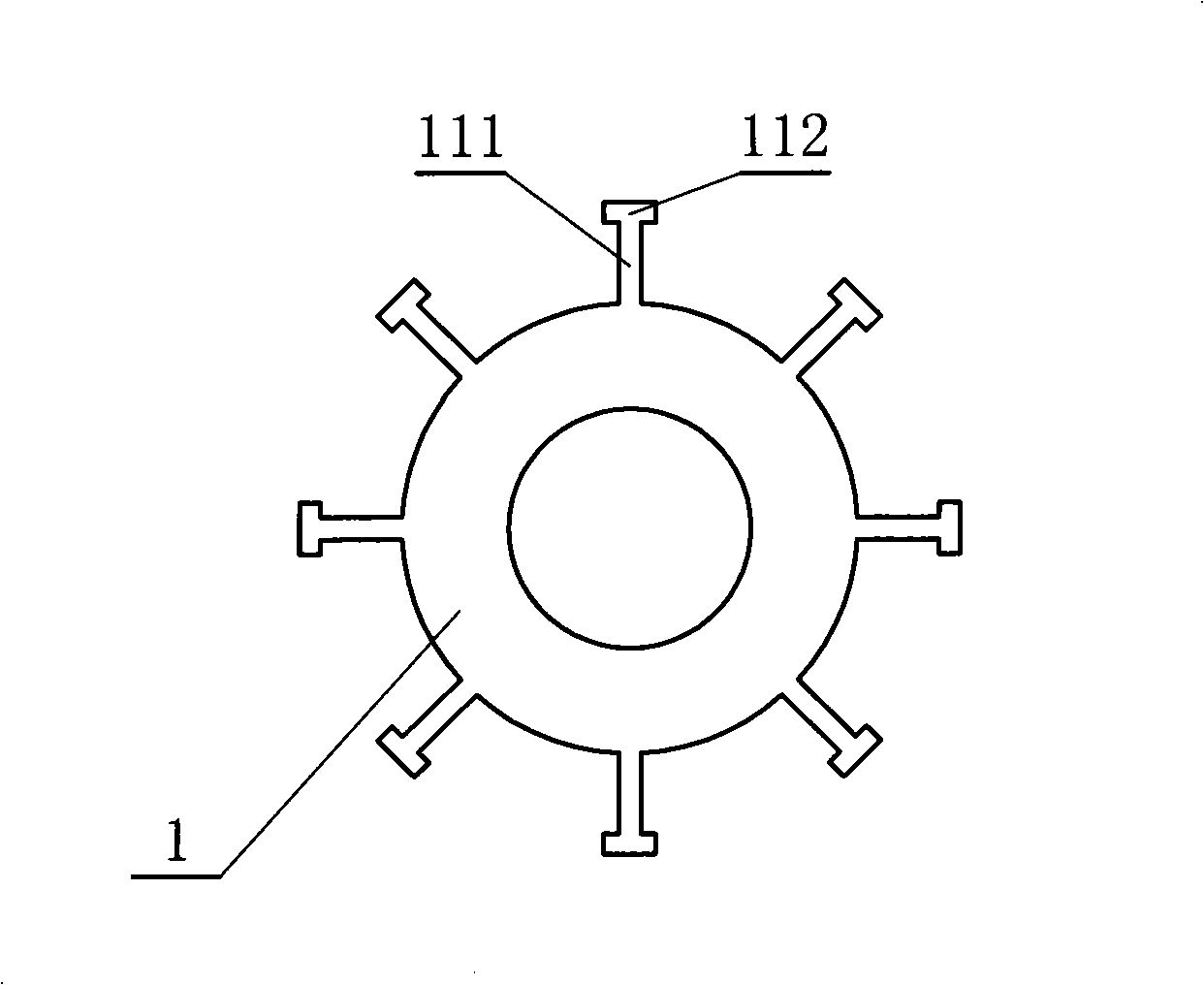

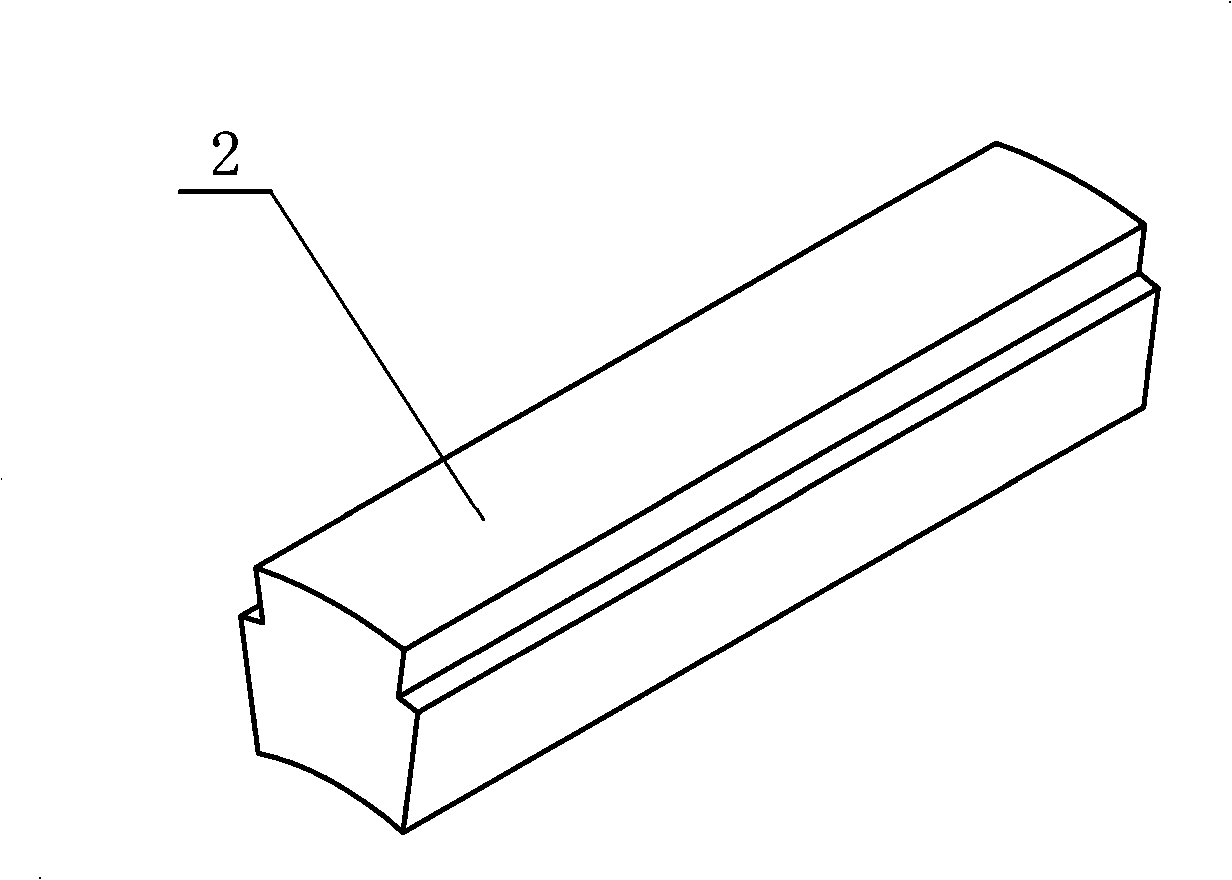

[0020] refer to Figure 1 to Figure 3 It is the first embodiment of a brushless motor rotor of the present invention, a brushless motor rotor, including a rotor core 1 and a magnetic steel 2, and eight motor rotor teeth 11 are arranged in the axial direction of the outer peripheral surface of the rotor core 1 , the motor rotor tooth 11 includes a connecting portion 111 and a limiting portion 112, the connecting portion 111 is rectangular, one end is provided on the outer peripheral surface of the rotor core 1, and the other end is provided with a limiting portion 112, and the limiting portion 112 is also It is rectangular, and the left and right ends are respectively 0.2-1 mm wider than the connection part 111. The rotor core 1 is made of silicon steel sheets or silicon steel sheets 12 with a thickness of 0.2-2 mm; the cross-section of the magnetic steel 2 is Sector shape, the shape of the two side planes is adapted to the shape of the rotor teeth 11 of the motor.

[0021] Wh...

Embodiment 2

[0023] refer to Figure 4 , Figure 5 It is the second embodiment of a brushless motor rotor of the present invention. A brushless motor rotor includes a rotor core 1 and a magnetic steel 2. Eight motor rotor teeth 11 are arranged in the axial direction of the outer peripheral surface of the rotor core 1. The motor rotor teeth 11 have an inverted trapezoidal cross-section, and the shorter end is arranged on the outer peripheral surface of the rotor core 1. The rotor core 1 is formed by superimposing silicon steel sheets or silicon steel sheets 12 with a thickness of 0.2 mm. The cross section of the magnetic steel 2 is fan-shaped, and the shape of the two sides matches the shape of the motor rotor teeth 11 .

[0024] When in use, a magnet 2 is inserted between two adjacent motor rotor teeth 11 of the rotor core 1, the two adjacent magnets 2 are N poles, and the two adjacent magnets are S poles With such an alternate arrangement, eight magnets 2 and several rotor cores 1 form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com