Radiating component and radiating method

A technology for heat-dissipating components and heat-generating components, applied in electrical components, electric solid-state devices, semiconductor devices, etc., can solve problems such as high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

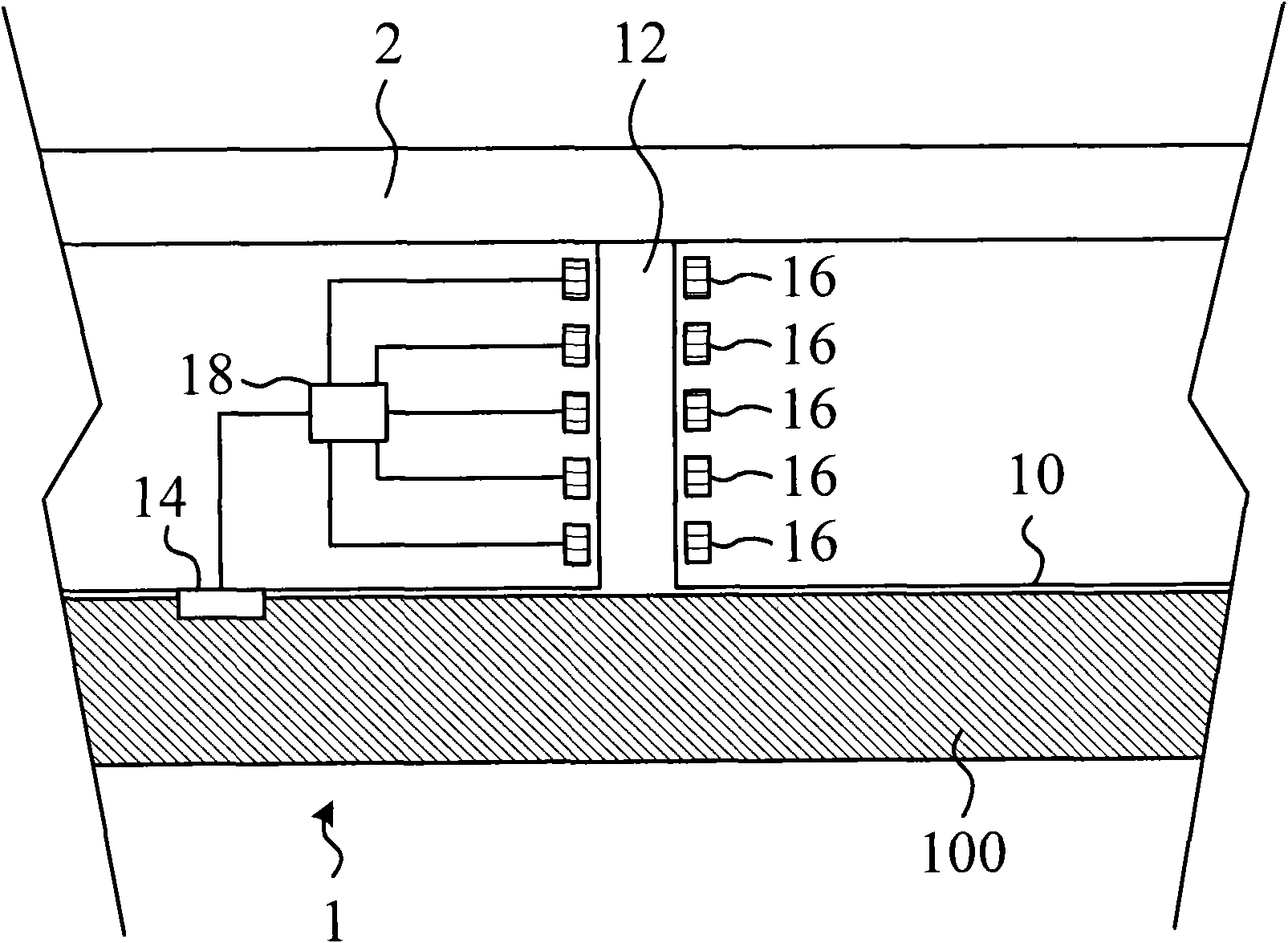

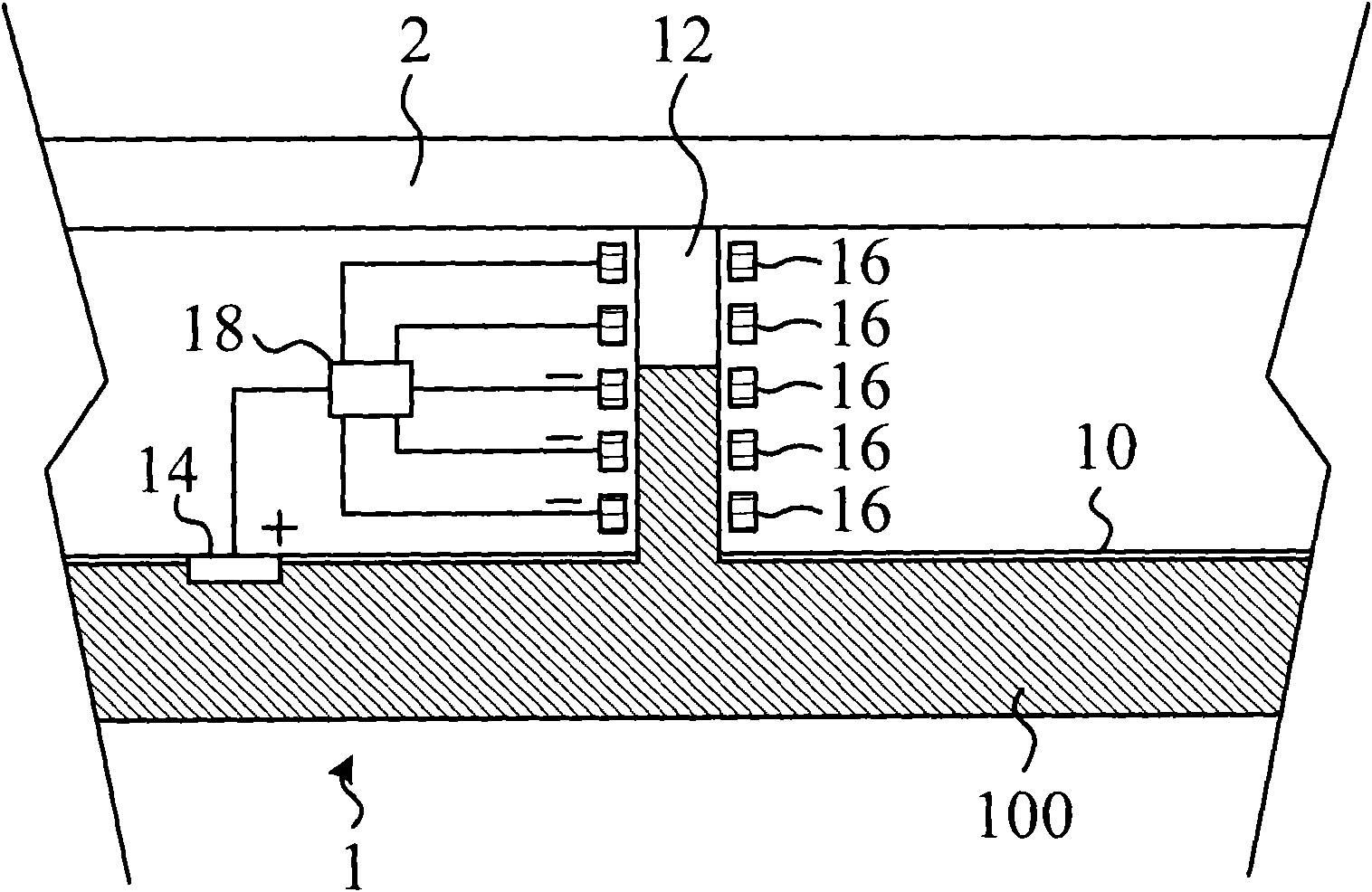

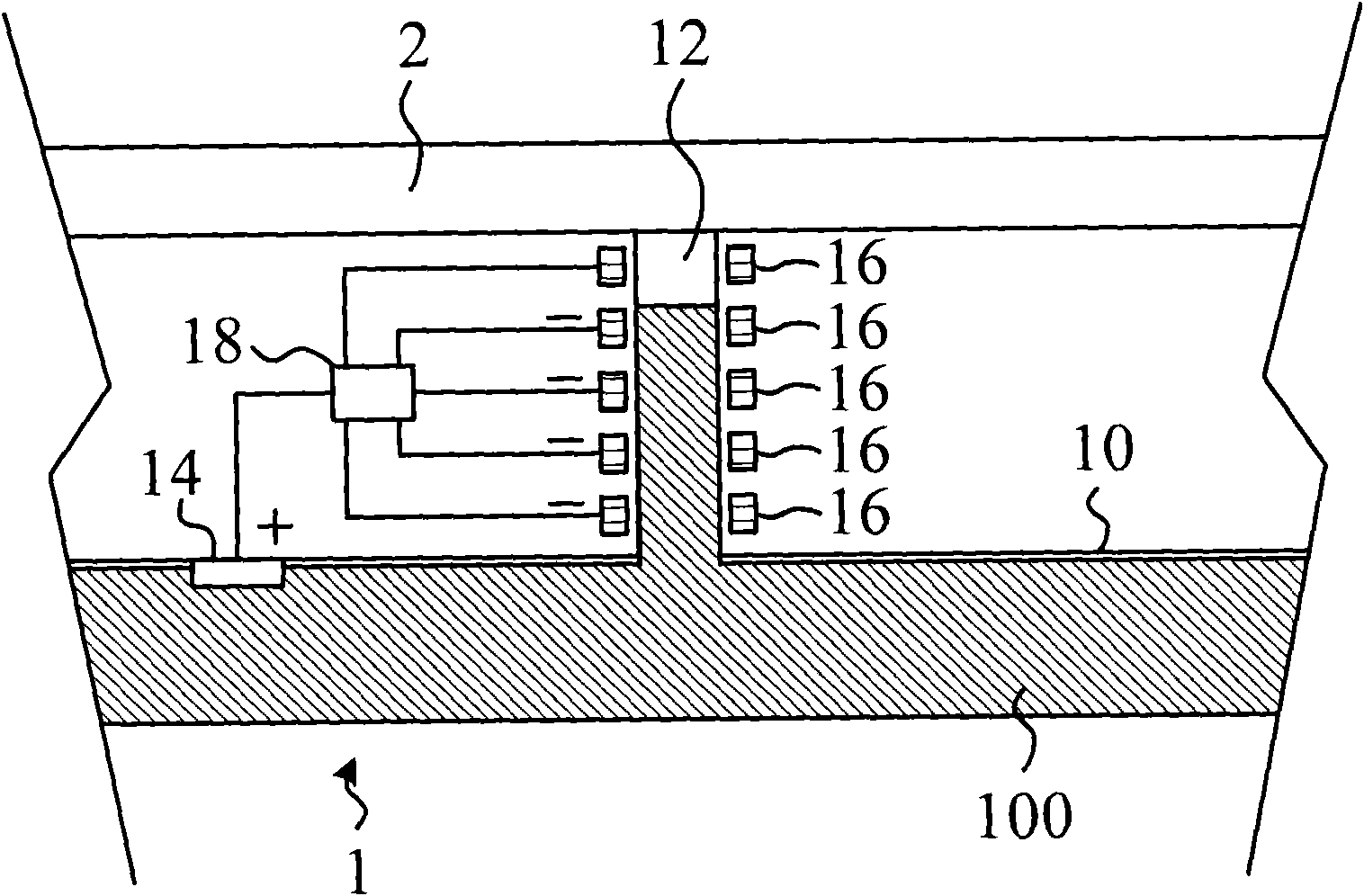

[0041] refer to Figure 1A , Figure 1B as well as Figure 1C , Figure 1A A cross-sectional view of a heat dissipation assembly 1 according to a specific embodiment of the present invention is described; Figure 1B as well as Figure 1C Described Figure 1A A schematic diagram of the first electrode 14 and the second electrode 16 being energized. Such as Figure 1A As shown, the heat dissipation component 1 includes a fluid cavity 10 , a micro-channel 12 , a first electrode 14 and a second electrode 16 . The fluid cavity 10 is used for containing a fluid 100 . The microchannel 12 branches and extends from the fluid chamber 10 , and the other end of the microchannel 12 is close to the heat generating component 2 . Please note that the micro-channel 12 directly contacts the heating component 2 in this specific embodiment, but in practical applications, the heating component (such as a chip) is generally arranged on one side of the circuit board, so the micro-channel can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com