Improved hose

A hose, tubular technology, used in the field of hoses for low temperature applications, can solve problems such as no solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

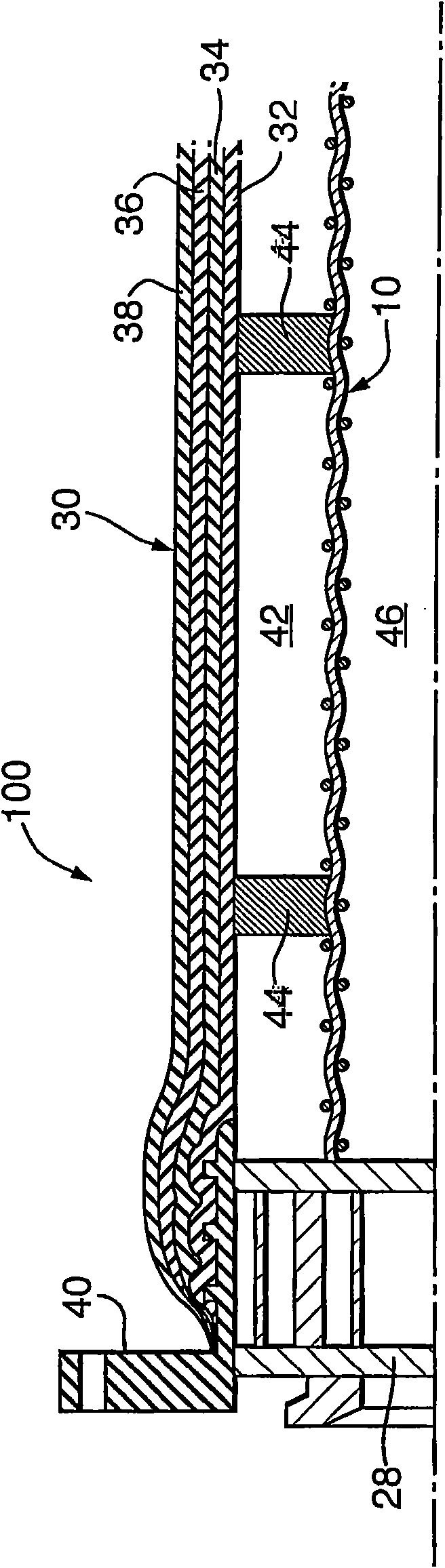

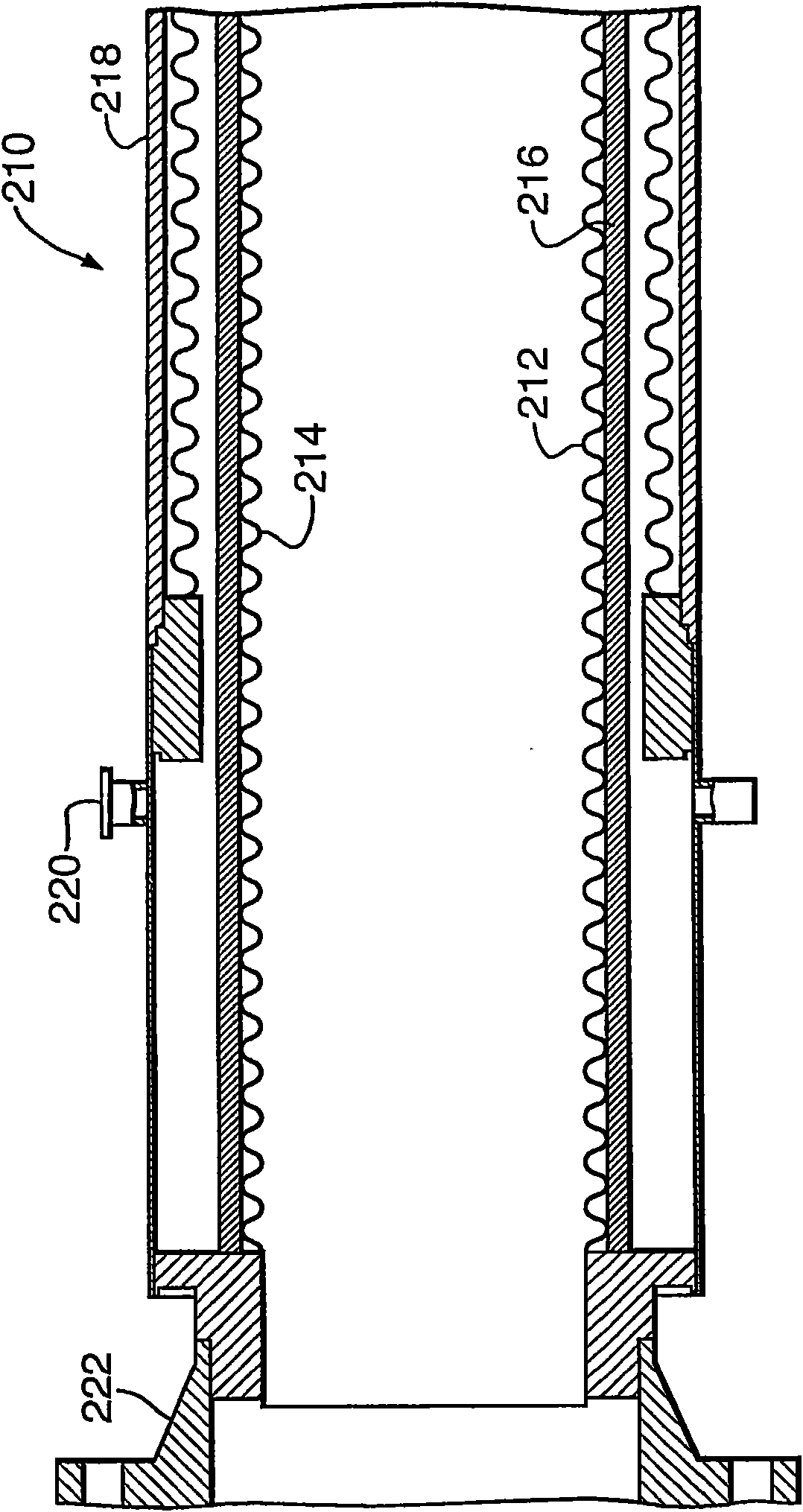

[0131] see first figure 1 and 2 , a hose according to the invention is indicated generally at 100 . The hose comprises an inner tubular structure 10 and an outer tube 30 .

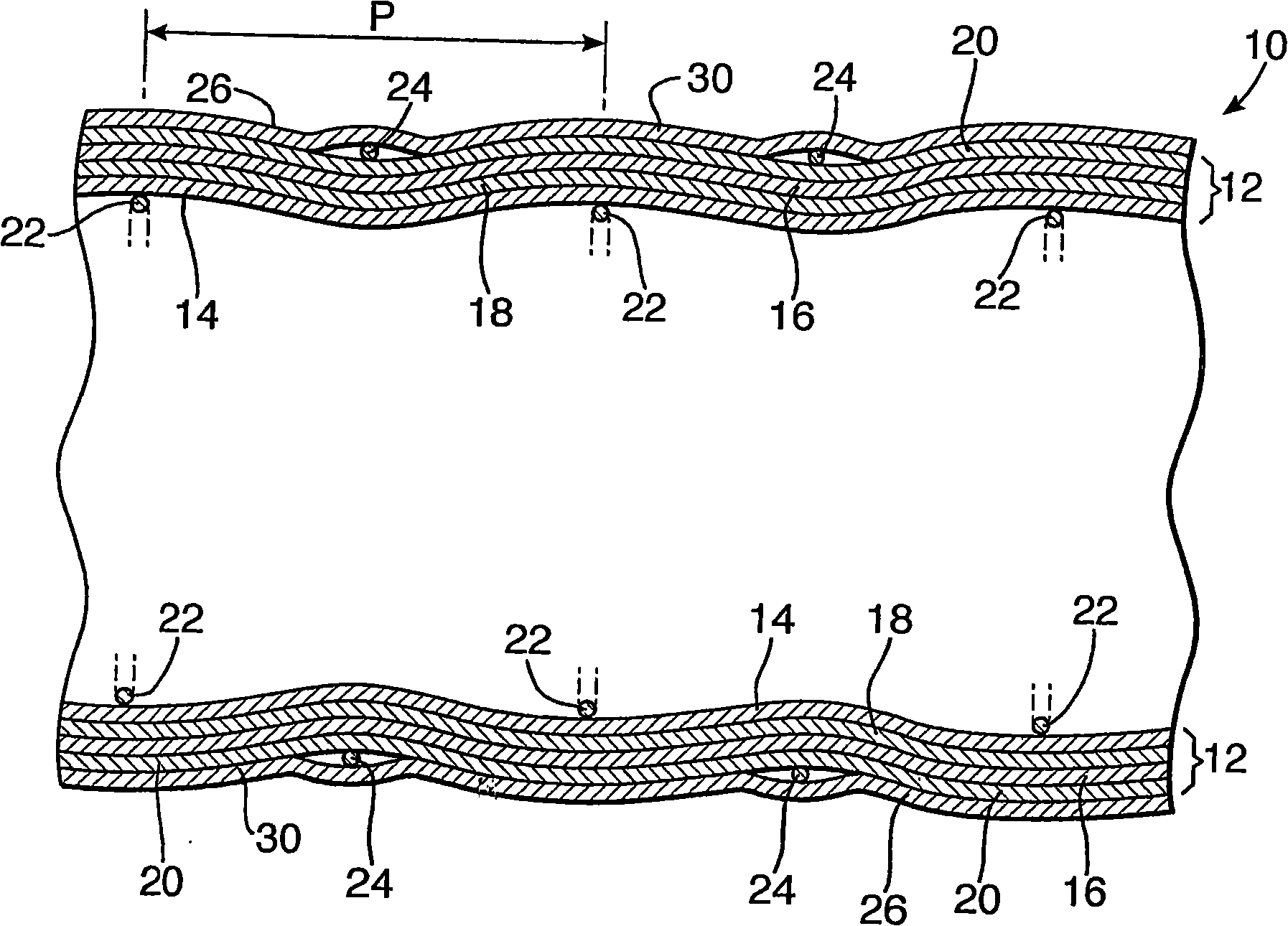

[0132] The inner tubular structure 10 comprises a tubular body 12 comprising an inner reinforcement layer 14 , an outer reinforcement layer 16 , and a sealing layer 18 sandwiched between layers 14 and 16 . A generally tubular sheath 20 in the form of webbing for providing axial reinforcement is arranged around the outer surface of the outer reinforcement layer 16 .

[0133] The tubular body 12 and the tubular sheath 20 are located between clamping members in the form of an inner helical coil wire 22 and an outer helical coil wire 24 . The inner and outer wires 22 and 24 are arranged such that they are offset from each other by a distance corresponding to half the pitch length of the coil.

[0134] An insulating layer 26 is disposed around the outer wire 24 . The insulating layer 26 may be, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com