A ladder continuous tea-carding machine

A technology of strip sorting machine and ladder, applied in the field of continuous tea strip sorting machine, can solve the problems such as difficulty in guaranteeing the quality of tea strip sorting, poor sorting effect, setting different frequencies, etc., so as to achieve uniform strip shape, reasonable structure design and high quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

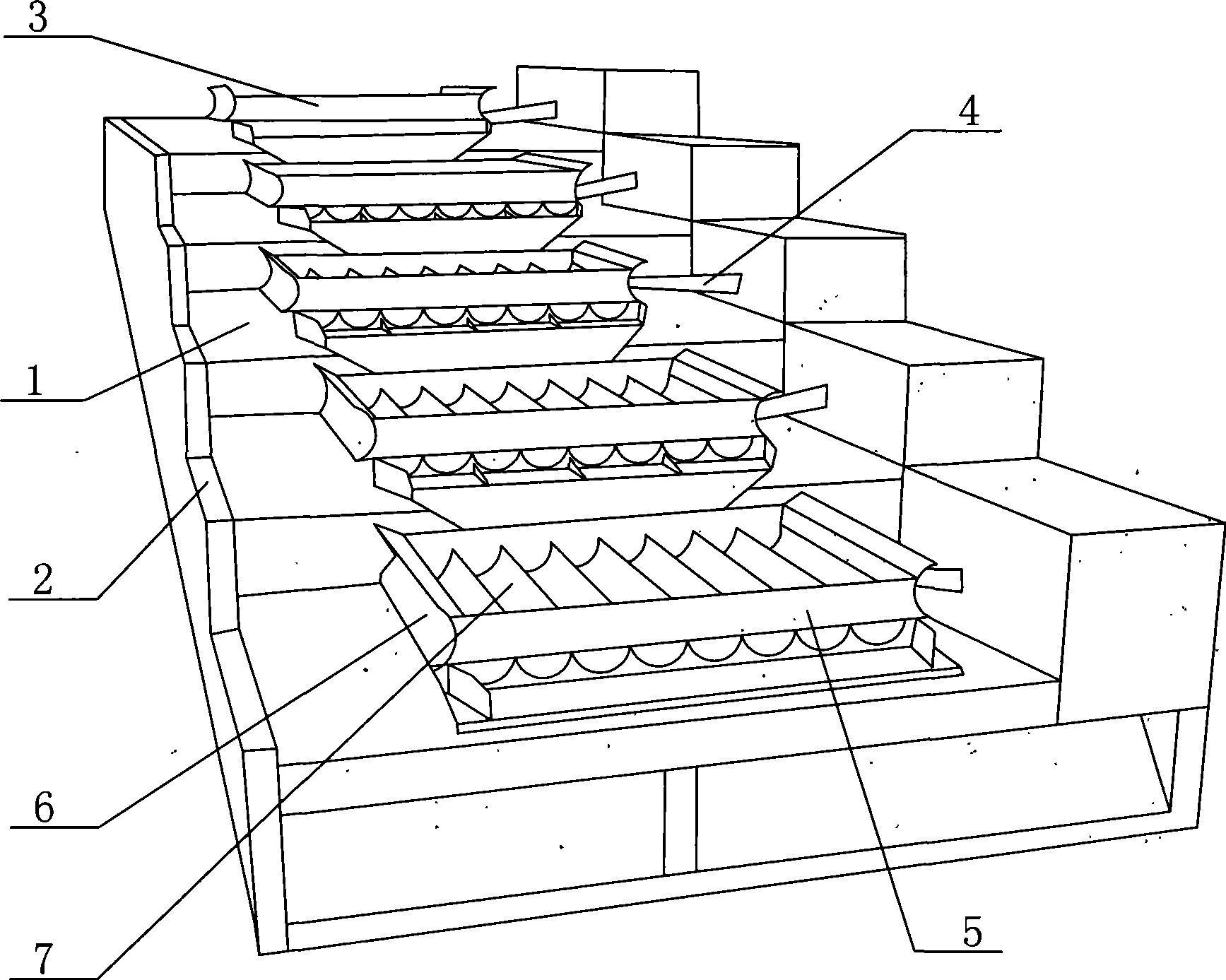

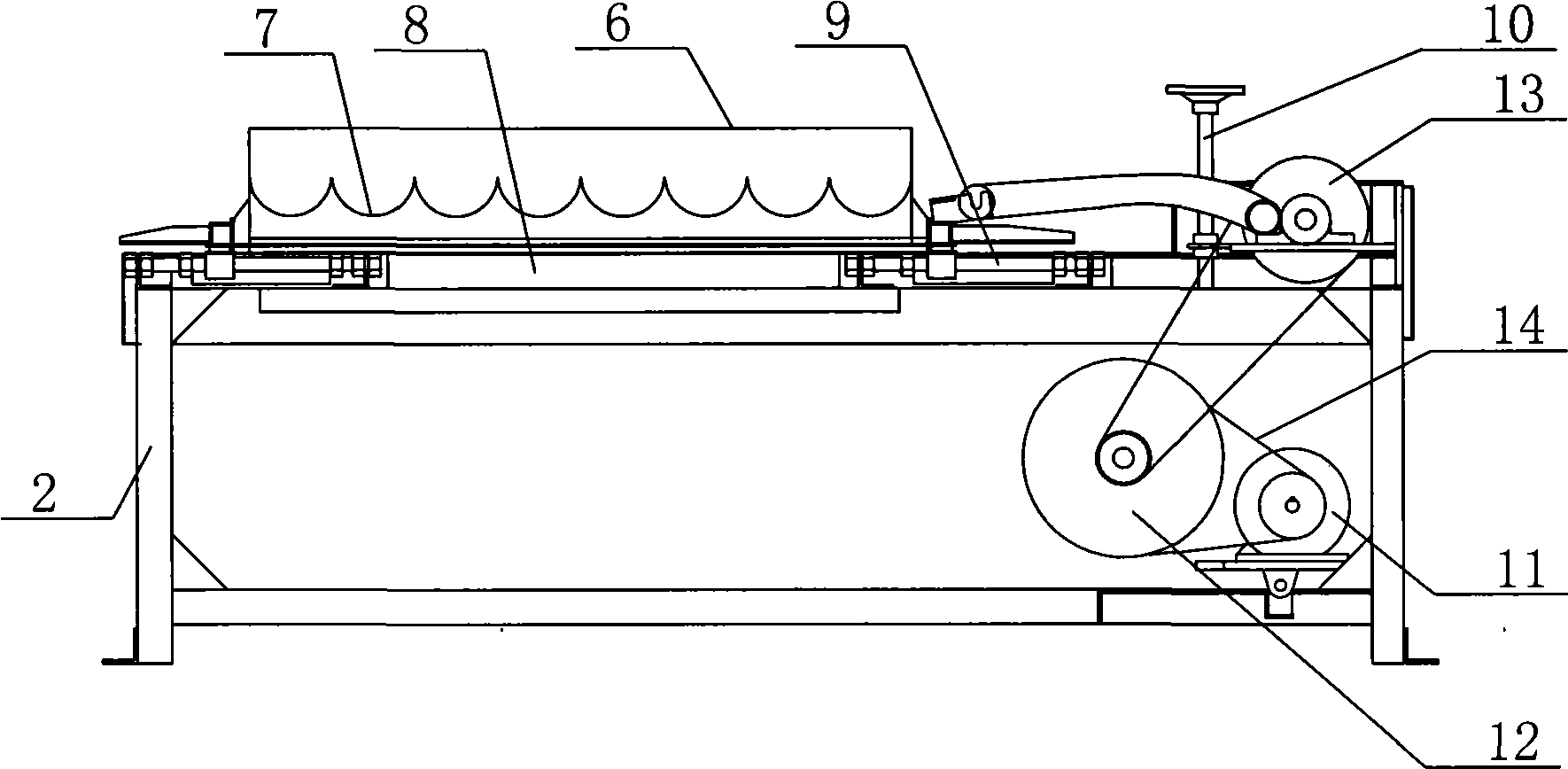

[0019] figure 1 , figure 2 Among them, a ladder continuous pruning machine includes a single pruning machine 1, and the single pruning machine 1 includes a frame 2, a driving mechanism, an electric heating device 8, and a pot support 6 that moves back and forth above the frame 2, and the pot support 6 is equipped with an open multi-slot pot 7, the cross-section of the multi-slot pot 7 is a U-shaped structure, and eight pots are arranged. Four of the single rafting machines 1 are arranged in steps to form a whole. An inclination angle adjustment screw rod is provided, which can be used to adjust the inclination angle of the multi-groove pot 7 of the monomer sliver machine 1 longitudinally. Usually, the longitudinal inclination angle of the multi-groove pot 7 of the single texturing machine 1 is 1 degree. The drive mechanism includes a motor 11, a large pulley 12, a middle pulley 13, and a transmission V-belt 14, etc. The motor 11 can drive the large pulley 12 and the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com