Method and device for detecting material lack of ice cream machine

An ice cream machine and detection method technology, which is applied to measurement devices, frozen desserts, speed/acceleration/impact measurement, etc., can solve problems such as increased production costs, increased labor costs, and difficulty in ensuring reliability, and achieves fewer failure points. , Simple control principle, low cost and low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

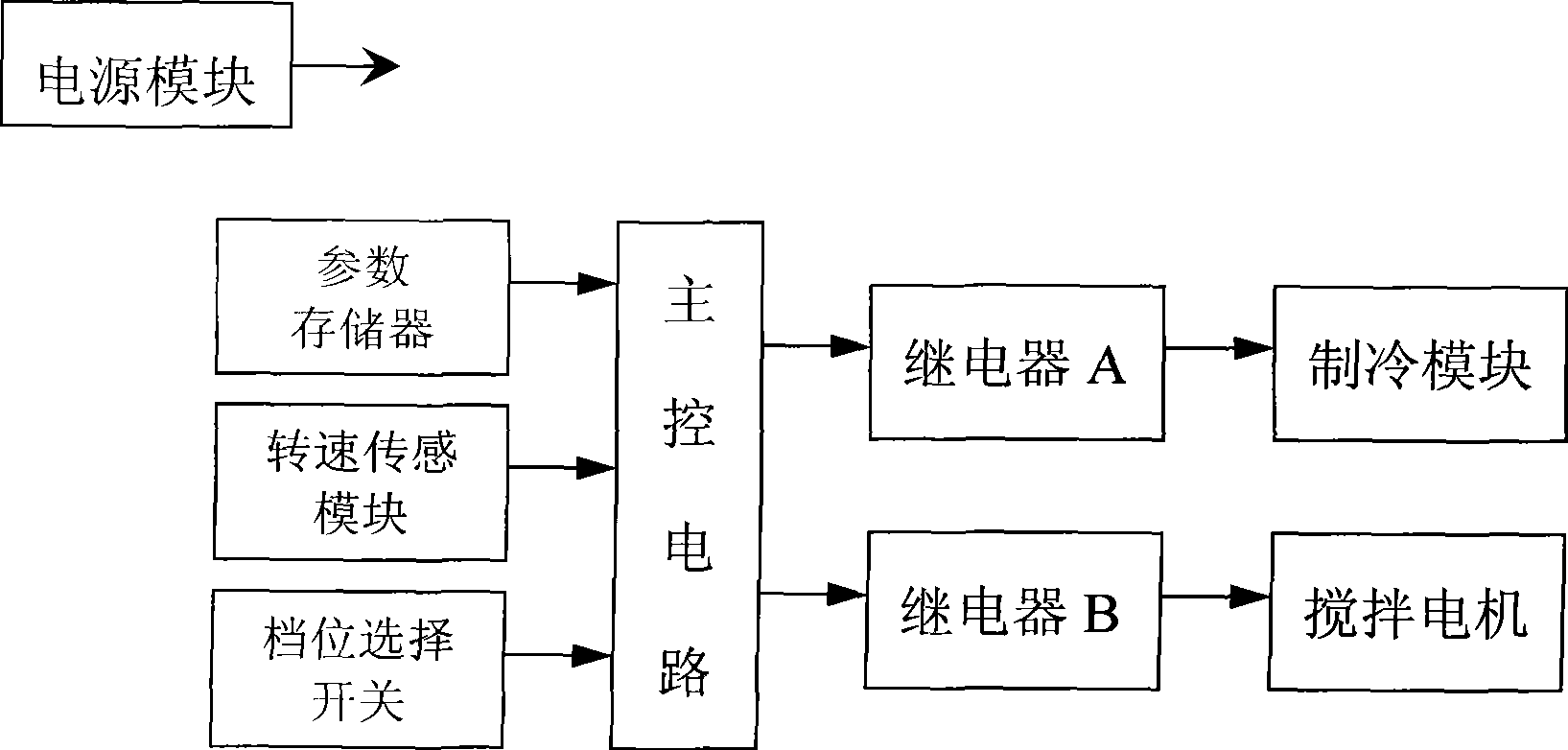

Image

Examples

Embodiment Construction

[0022] The method for detecting material shortage of an ice cream machine provided by the present invention firstly detects the rotation speed of the material cylinder of the ice cream machine through a rotation speed sensor, and when it is detected that the rotation speed of the material cylinder remains below the alarm threshold for a certain period of time, a material shortage alarm signal is issued and the alarm state is maintained for a certain period of time; If the speed of the material cylinder rises above the alarm threshold after the alarm signal is sent, the alarm state will be released; if the speed of the material cylinder remains below the alarm threshold for a certain period of time after the alarm signal is sent, it will be forced to stop and the alarm signal will be sent again.

[0023] In the above-mentioned detection method, the fixed time maintained before the alarm is set to 90 seconds, the fixed time maintained after the alarm is set to 30 seconds, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com