Extrusion device of conical twin-screw extruder special for polyolefine

A conical twin-screw and conical-screw technology, which is applied in the field of extrusion devices of conical twin-screw extruders, can solve the problems of inability to plasticize and knead polyolefin materials, achieve increased pressure, low energy consumption, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

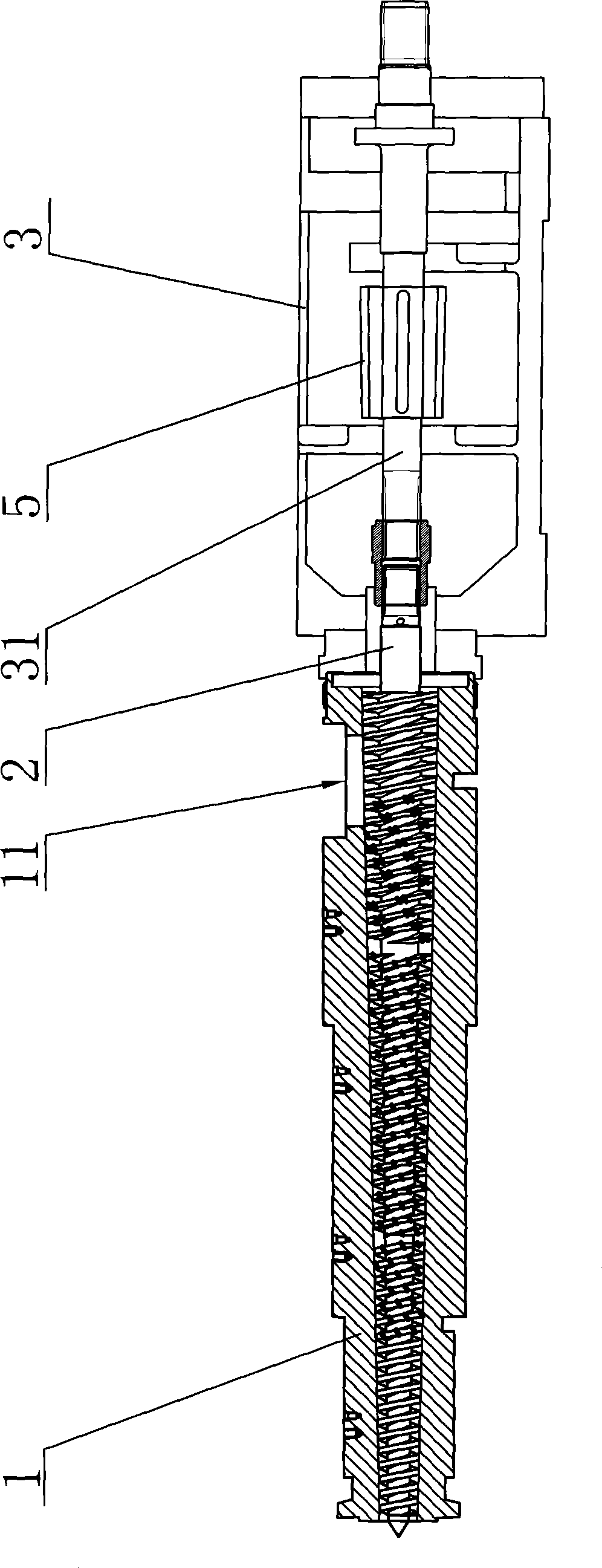

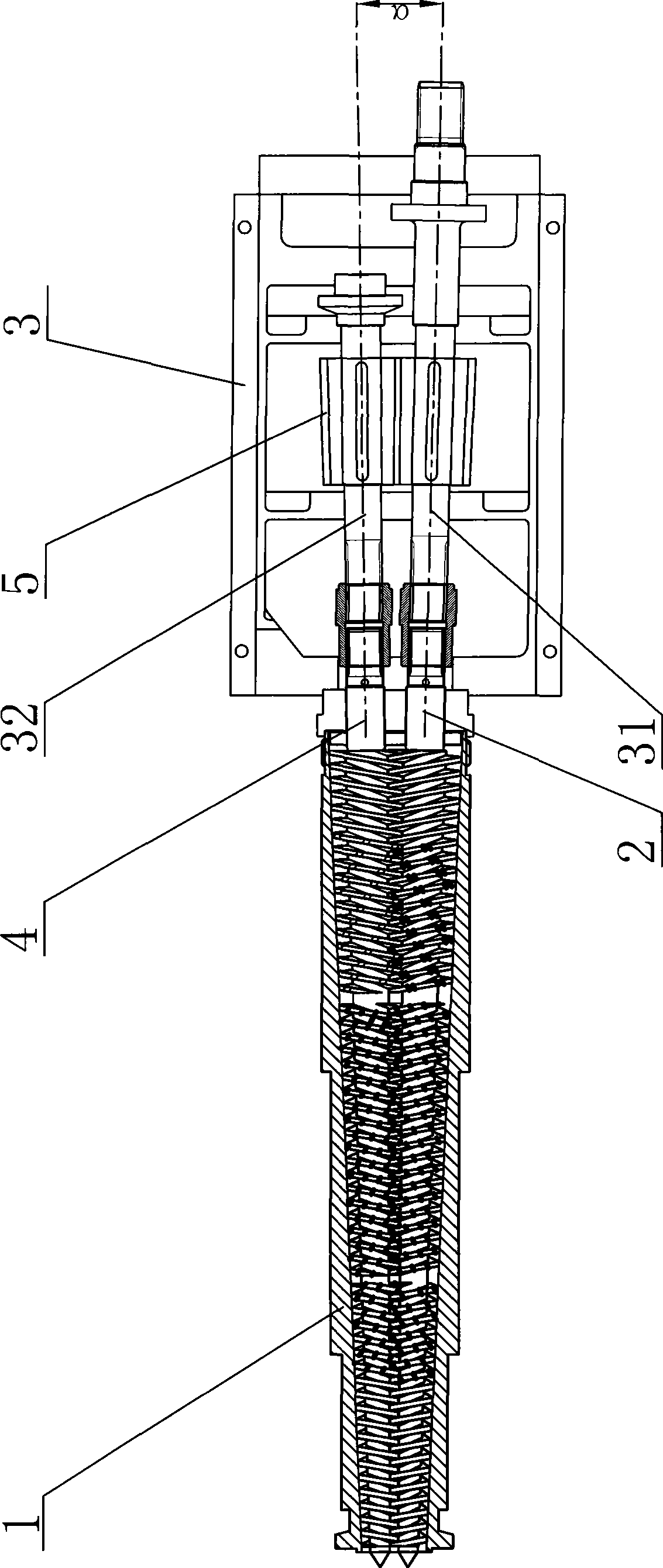

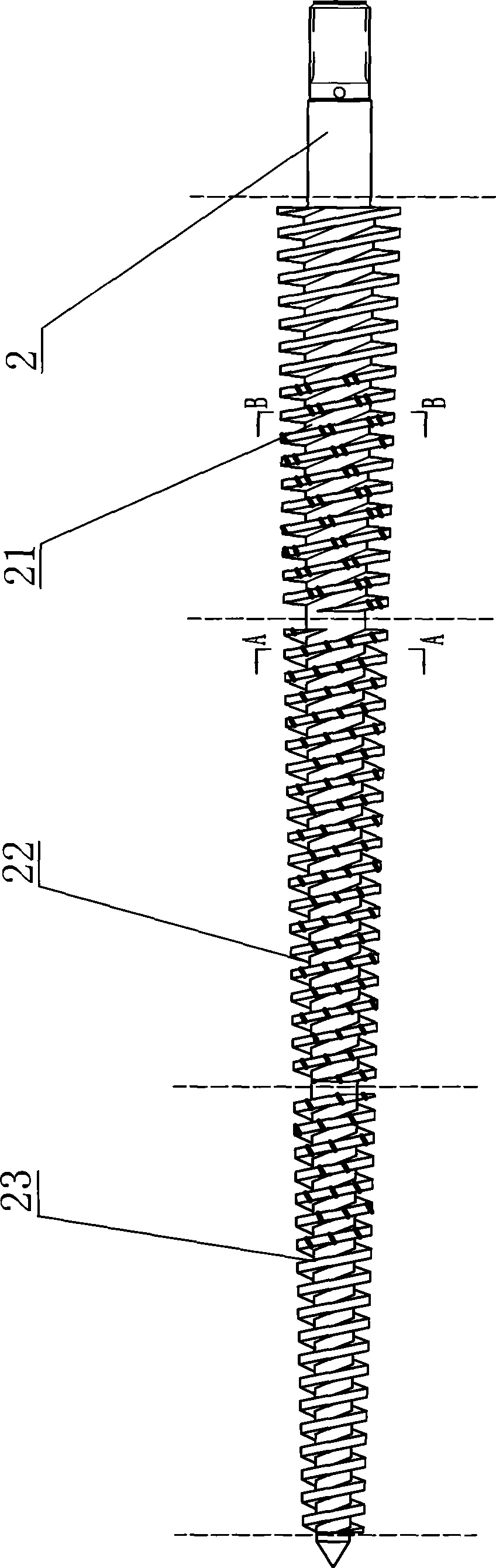

[0015] Such as figure 1 As shown, the extrusion device of the special conical twin-screw extruder for polyolefin includes: a barrel 1, a pair of conical screws are arranged in the barrel 1, and a feed inlet 11 is arranged on the barrel 1. Such as image 3 As shown, each conical screw is provided with a feed section 21, a compression section 22 and a plasticizing and homogenizing section 23 with a total of three sections of flight, and the lead of the compression section 22 flight is 40 to 58 mm. . Such as figure 1 , figure 2 As shown, the position of the feed port 11 corresponds to the feed section 21 on the conical screw 2, wherein the flight length of the compression section 22 is 35% to 45% of the total length of all flight flights on the conical screw, and in the whole The flight of the compression section 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com