Method for preparing composite material of silicon carbide of biological appearance and molecular sieve

A composite material and molecular sieve technology, which is applied in the field of preparation of biomorphic porous silicon carbide and molecular sieve composite materials, to achieve the effect of facilitating the transmission of matter and energy, overcoming poor thermal conductivity, and uniform and stable load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 17ml of tetrapropylammonium hydroxide (TPAOH) to 20ml of water to dissolve, add 0.6g of sodium hydroxide to it, stir for 30 minutes to fully mix the two; then add sodium metaaluminate (NaAlO 2 , 0.246g) of 10ml of aqueous solution, continued to stir for 30min, then slowly added 22.4ml of tetraethyl orthosilicate (TEOS) dropwise, and stirred at room temperature for 6 hours to obtain a sol of ZSM-5 molecular sieve.

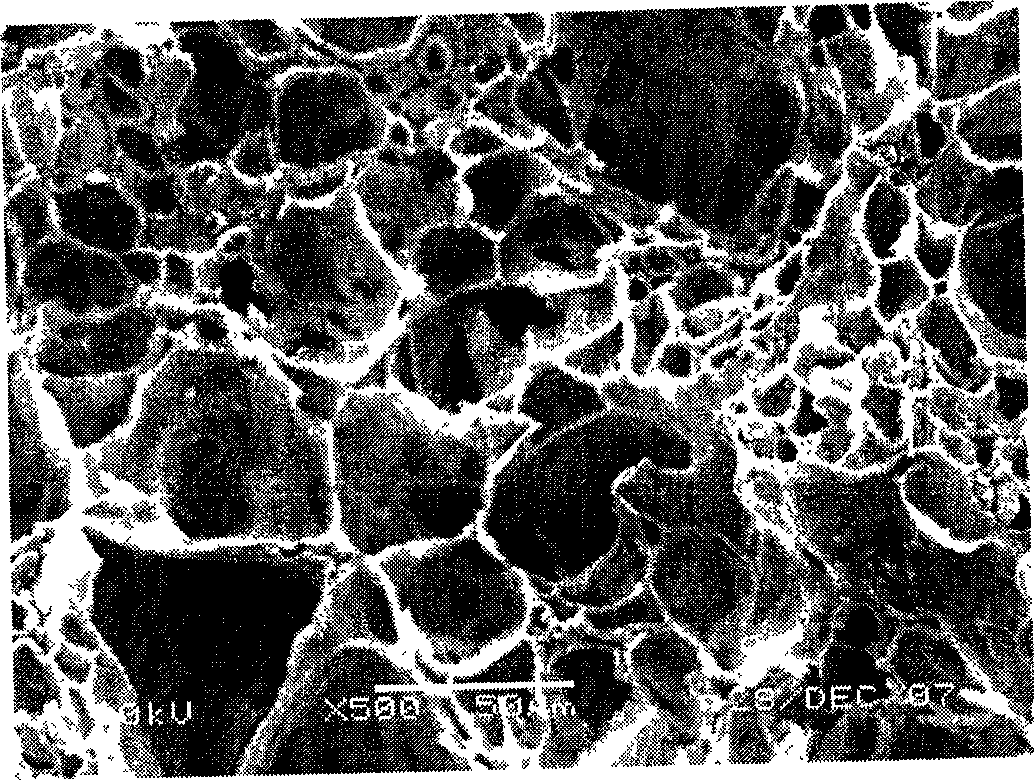

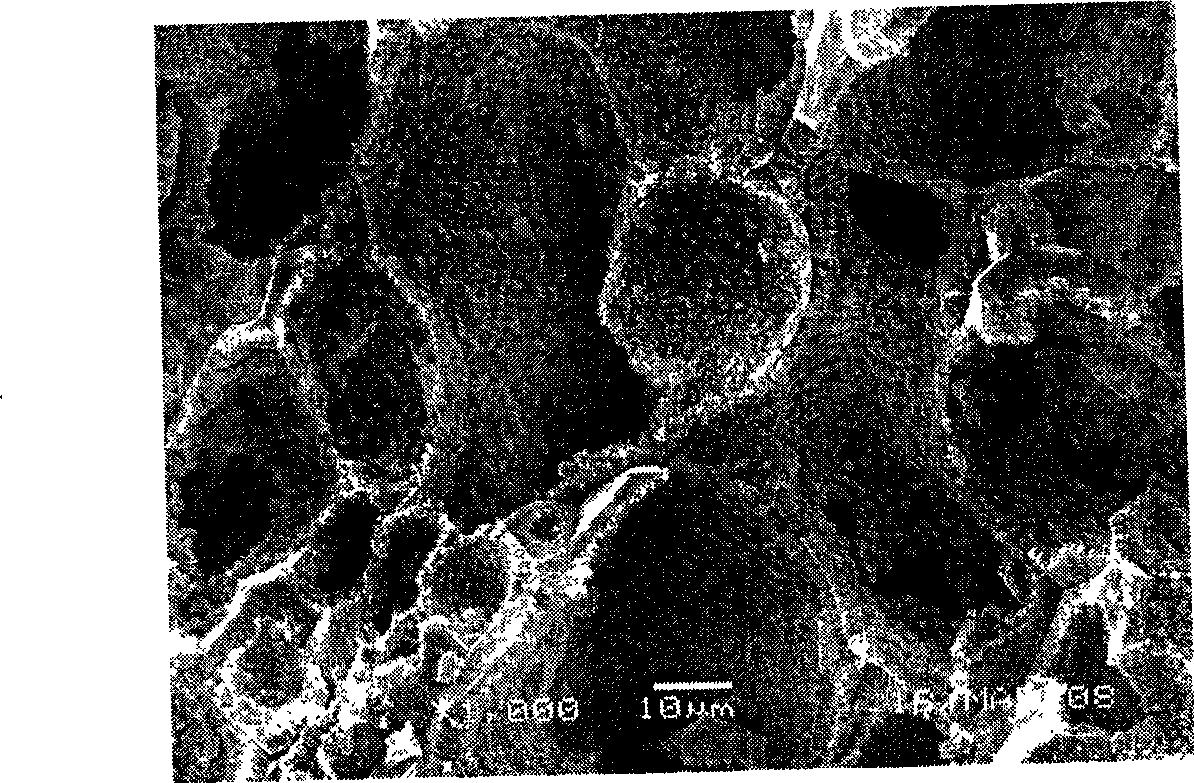

[0030] Put the dried sorghum into a tube furnace, and carbonize at 600°C for 5 hours under the protection of argon; take 28 grams of silicon powder and 12 grams of carbonized biomass, mix them thoroughly, and put them in a high-temperature furnace under the protection of argon. Keep the temperature at 1200°C for 5 hours. Then treat in air at 600°C for 4 hours to remove unreacted carbon, pickle with nitric acid and hydrofluoric acid (1:3) for 36 hours to remove unreacted silicon, and obtain spherical porous SiC.

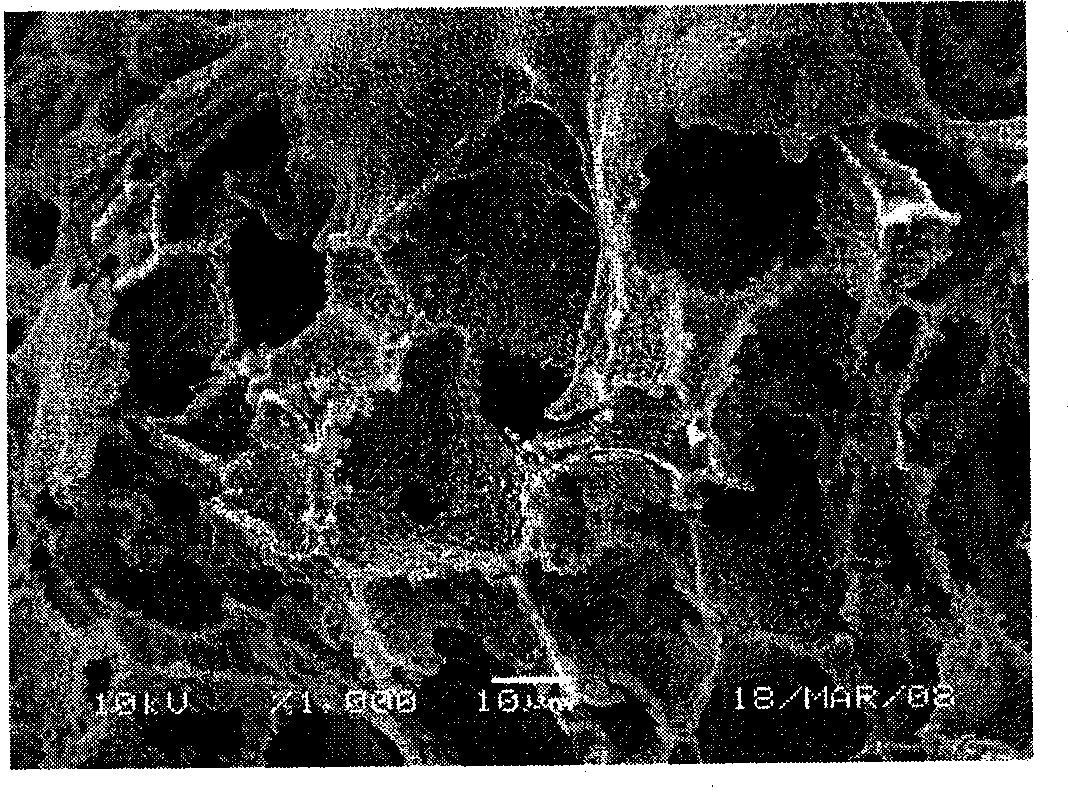

[0031]Take 0.4 g of the above-mentioned b...

Embodiment 2

[0033] 25.5ml of tetrapropylammonium hydroxide (TPAOH) was added into 30ml of water to dissolve, 0.6g of sodium hydroxide was added thereto, stirred for 30 minutes to fully mix the two; then aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 (2, 2g) aqueous solution 15ml, continue to stir for 30min and then slowly add 22.4ml tetraethyl orthosilicate (TEOS) dropwise, and stir at normal temperature for 10 hours to obtain the sol of ZSM-5 molecular sieve.

[0034] Put the dried millet into a tube furnace, and carbonize at 800°C for 3 hours under the protection of argon; take 34 grams of silicon powder and 6 grams of carbonized biomass, mix them thoroughly, and put them in a high-temperature furnace under the protection of argon. Inner 1300 ℃ constant temperature for 3 hours. Then treat in air at 400°C for 6 hours to remove unreacted carbon, pickle with nitric acid and hydrofluoric acid (1:6) for 24 hours, remove unreacted silicon, and obtain spherical porous SiC.

[0035] Take 0.6 g of t...

Embodiment 3

[0037] Add 2.6ml of n-butylamine (NAB) into 20ml of water to dissolve, add 0.3g of sodium hydroxide to it, stir for 30 minutes to make the two fully mixed; then add aluminum nitrate (Al(NO 3 ) 3 9H 2 (2.496g) of aqueous solution 10ml, continue to stir for 30min and slowly add 16.8ml of water glass (sodium silicate aqueous solution) dropwise, and stir at normal temperature for 6 hours to obtain the sol of ZSM-5 molecular sieve.

[0038] Put the dried sorghum into a tube furnace, and carbonize at 700°C for 10 hours under the protection of argon; take 16 grams of silicon powder and 5 grams of carbonized biomass, mix them thoroughly, and put them in a high-temperature furnace under the protection of argon. Inner 1350 ℃ constant temperature for 4 hours. Then treat in air at 500°C for 5 hours to remove unreacted carbon, pickle with nitric acid and hydrofluoric acid (1:4) for 72 hours to remove unreacted silicon, and obtain spherical porous SiC.

[0039] Take 0.3 g of the above-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com