Expandable sand control screen pipe

A sand control screen and screen technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem of weak tensile and torsion resistance of expansion and screw joints, and difficulty in forming high permeability oil circulation Road, increase the difficulty and cost of operations, etc., to reduce construction costs and risks, reduce movement and migration of particles, and reduce sand impact and erosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with the accompanying drawings of the description.

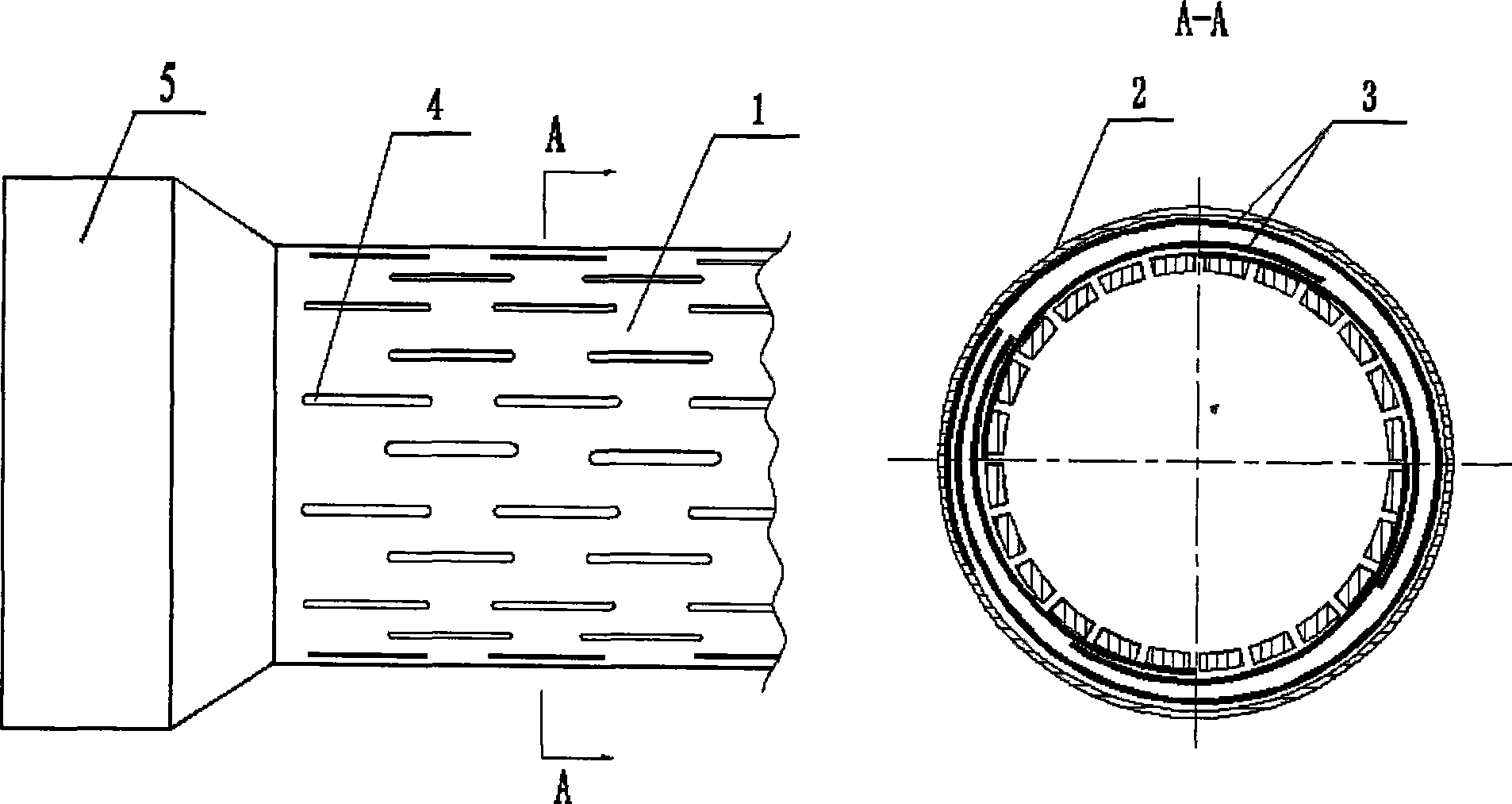

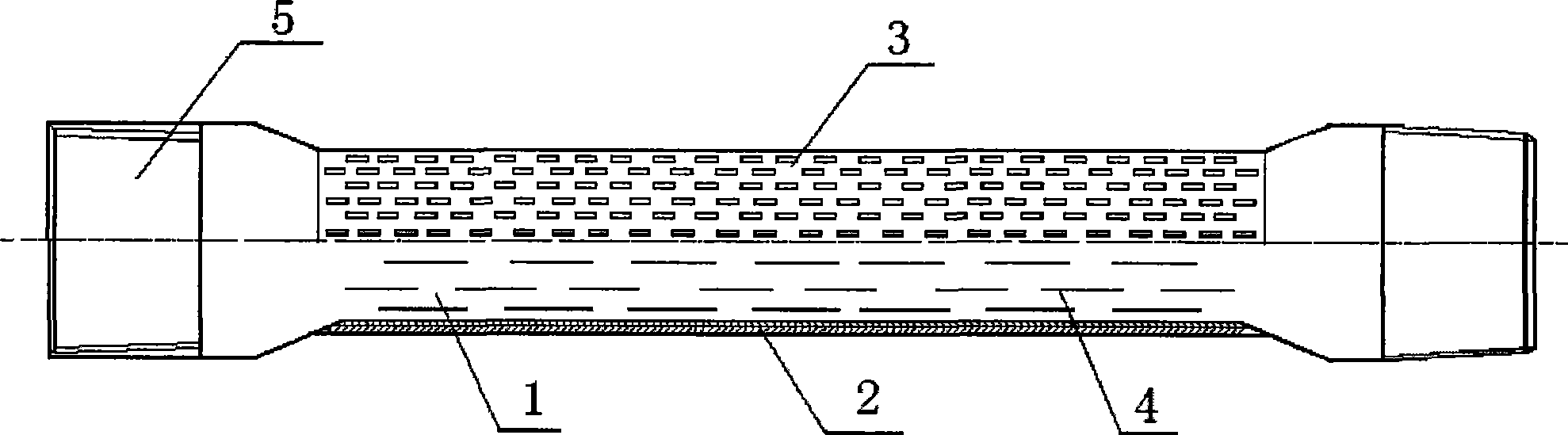

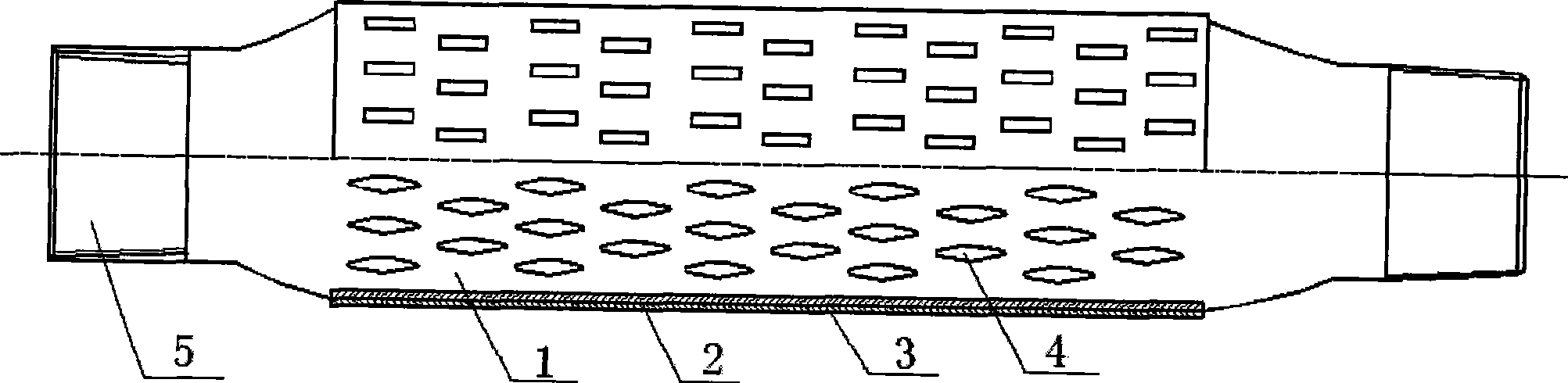

[0021] as attached figure 1 , figure 2 and image 3 As shown, the present invention is an expandable sand control screen, which is composed of a three-layer structure of an expansion base pipe 1, a filter medium 2 and a metal protection cover 3, and slots 4 are evenly cut in the axial direction of the expansion base pipe 1, and the slots 4 The fingers at both ends adopt circular arc transition structure, and the two ends of the expansion base pipe 1 are welded with expansion joints 5; One section of the sheet is fixed on the expansion base pipe 1, and the sheets are overlapped with each other, and the outer screen is fixed on the metal protective cover 3, adopting a self-lapping method, which is an integral structure; the filter medium 2 is covered with a metal protective cover 3. It is integrated with the expansion base pipe 1 by welding.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com