Integrally adjustable automatic water elevator unit

A water lifter and unit technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of being limited, reducing energy consumption, and not being easy to install, so as to reduce the effect of gravity, reduce mechanical losses, and facilitate water Available effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

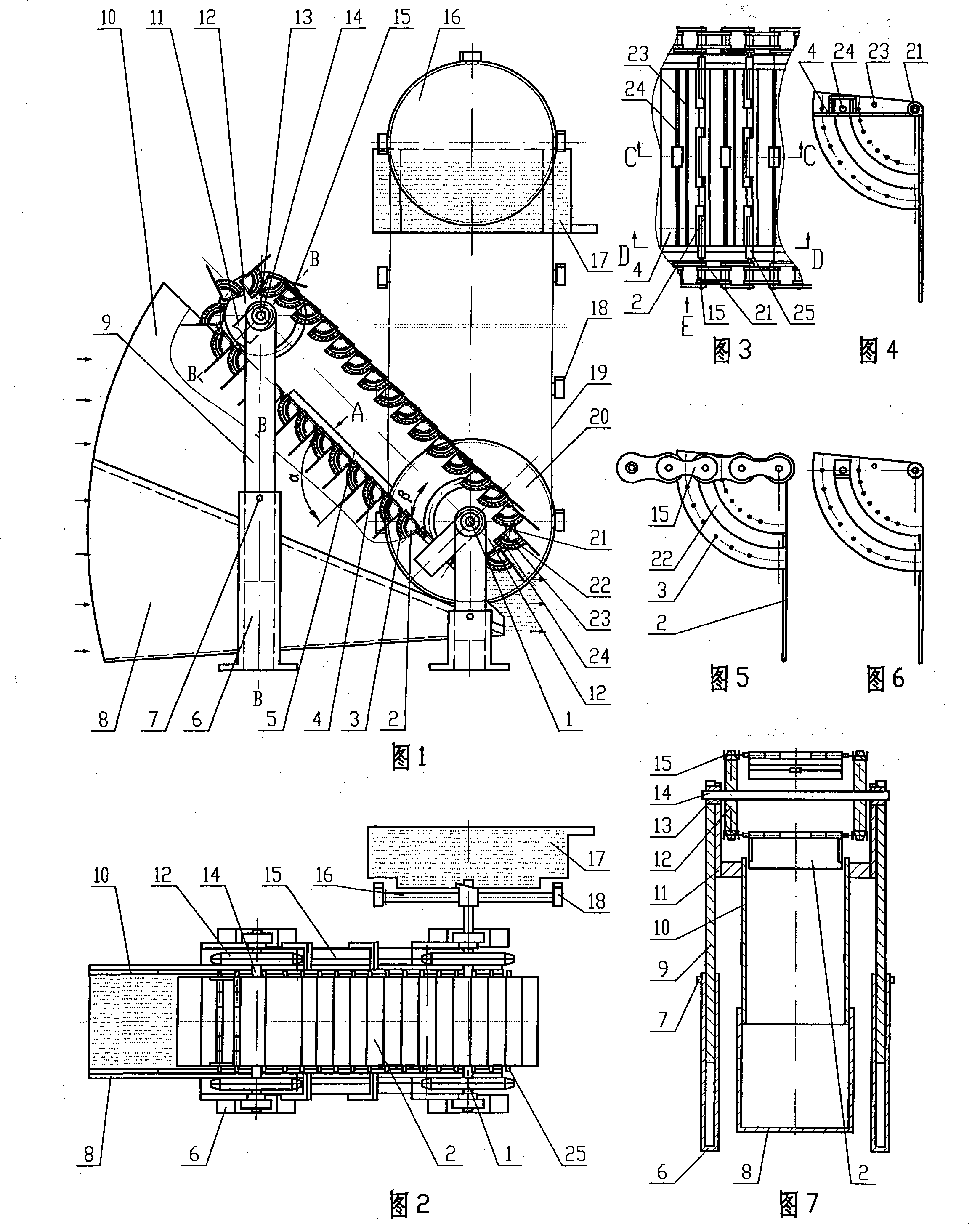

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, the present invention includes a water machine and a water lifter driven coaxially by the water machine, the driving sprocket shaft 1 and the driven sprocket shaft 14 of the water machine are installed on the lifting legs 9, and the chain belt plate 4 is coaxial The suit is equipped with an adjustable movable leaf bucket-shaped hydraulic plate 2, and the water energy machine also includes a U-shaped bottom groove 8 and baffles 10 on both sides, which form a pressure-type cone volume chamber with the chain belt plate 4; the water lifter is a single chain Type water lifter, the water lift sprocket 20 is installed on the driving sprocket shaft 1 of the water energy machine, and the closed single chain around the water lift sprocket 20 and the unloading sprocket 16 is hung with a movable leaf plastic cover 31 and The...

Embodiment 2

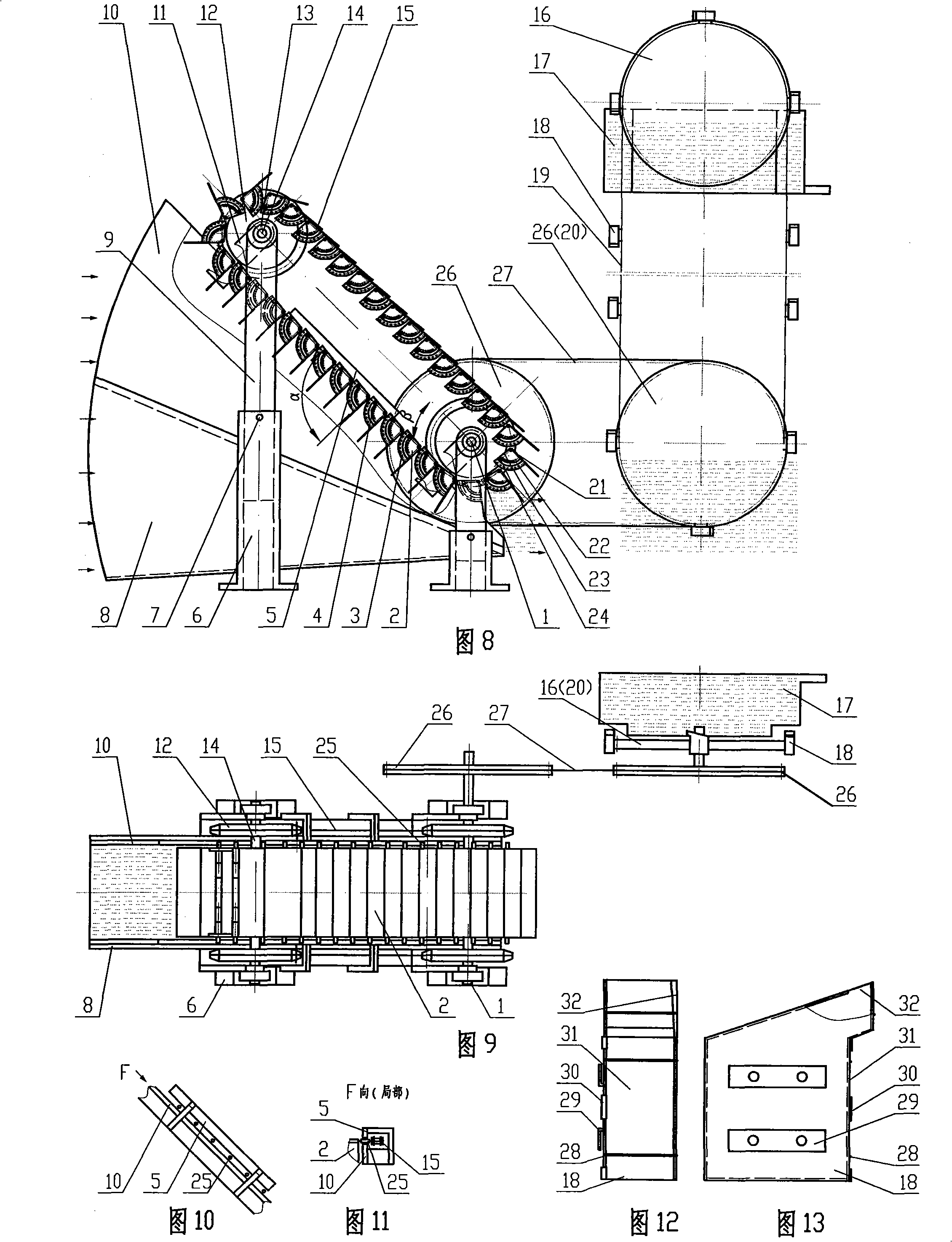

[0047] Such as Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, the present invention includes a water energy machine and a water lift driven by a different shaft of the water energy machine, and two drive sprockets 26, one coaxial with the drive sprocket shaft 1 of the water energy machine, and one with the water lift sprocket 20 coaxial, transmission chain 27 is arranged between two transmission sprockets 26, and water energy machine rotates, drives transmission sprocket 26 to rotate, and transmission sprocket 26 drives water lifting machine operation. All the other are the same as embodiment one.

Embodiment 3

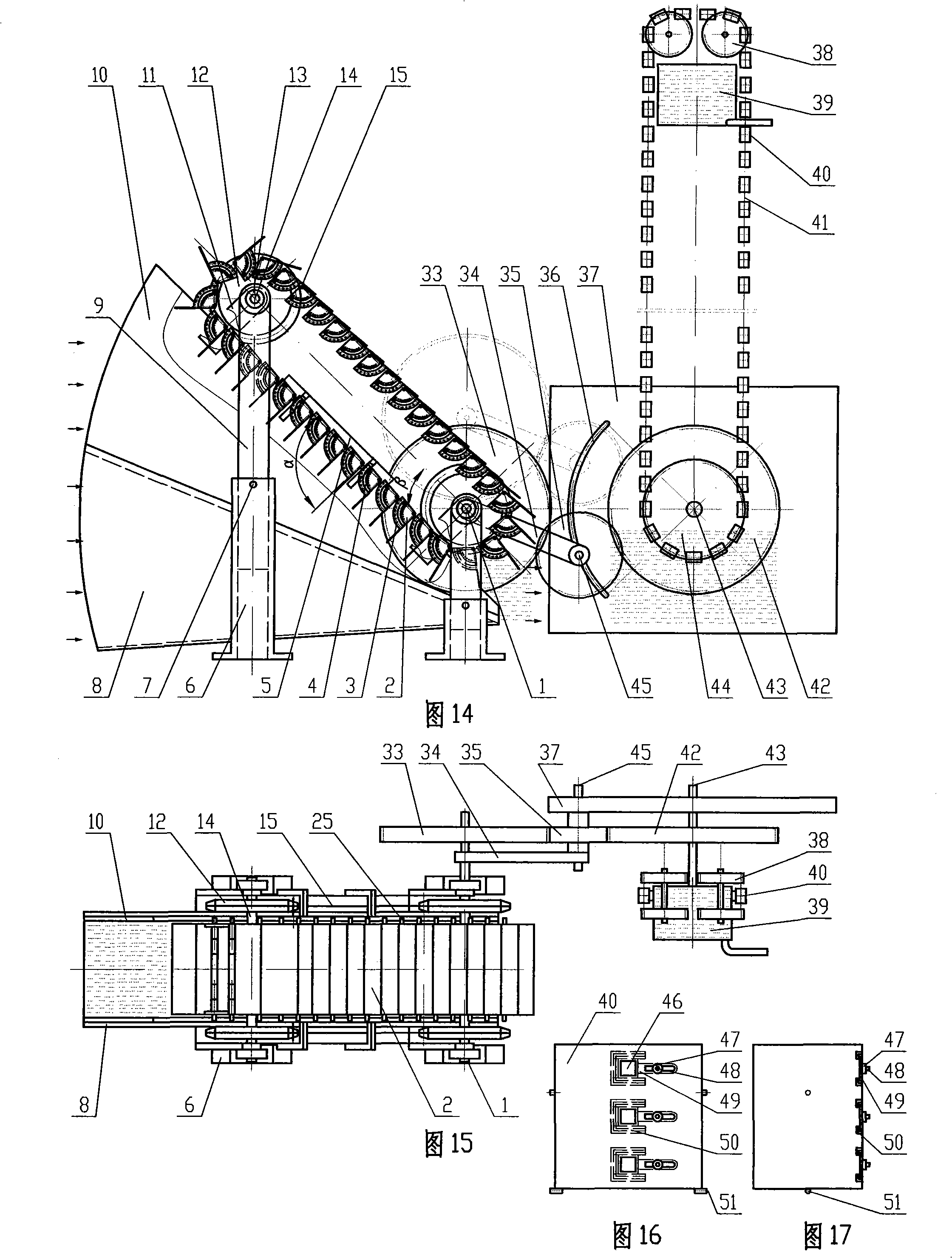

[0049] Such as Figure 14 , Figure 15 , Figure 16 , Figure 17 Shown, the present invention comprises water energy machine and double chain type water lifter and power transmission device, double chain type water lifter comprises two water lifting sprockets 44, four unloading sprockets 38, water collection tank 39, frame And have the frame plate 37 of arc groove 36, driven drive shaft 43 is installed on the frame plate 37 of band arc groove 36 coaxial with water-lifting sprocket wheel shaft, around water-lifting sprocket wheel 44 and unloading sprocket wheel 38 circles The water-lifting cylinder 40 with the push-pull plate water outlet 46 is hung on the closed double chain of the row; The clutch gear 35 on the clutch transmission shaft 45, the driven gear 42 coaxial with the water-lifting sprocket 44, the clutch connecting plate 34 is installed on the driving sprocket shaft 1 of the water energy machine, and the other end is installed on the clutch transmission shaft 45 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com