Electrostatic discharge protecting device of high-voltage cushion

An electrostatic discharge protection and electrostatic discharge technology, which is applied in the field of ESD protection devices, can solve the problems that the power supply voltage cannot have PMOS components, and the ESD protection capability of high-voltage I/O pads is difficult to improve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

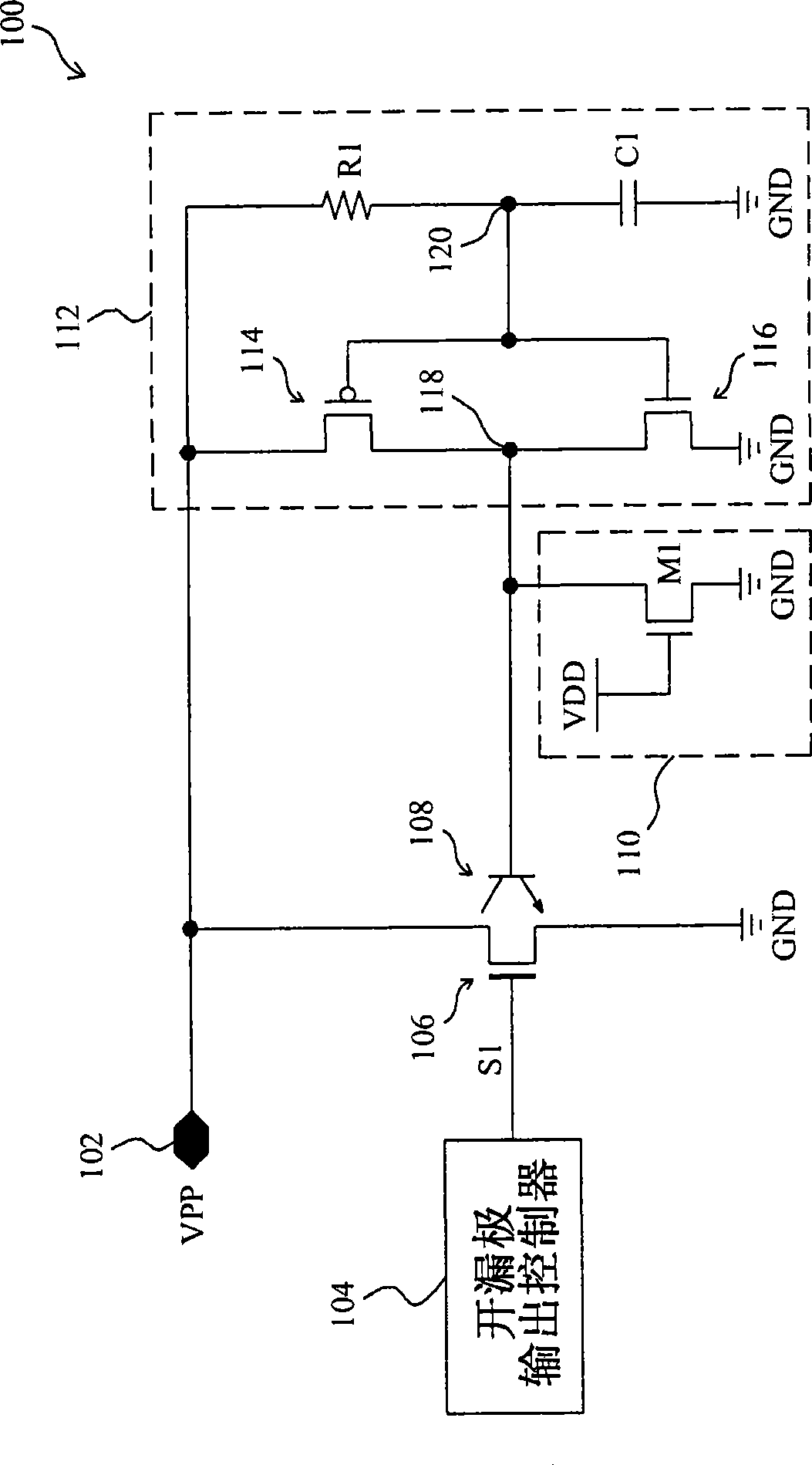

[0041] figure 1 It is the first embodiment of the present invention. In the ESD protection device 100, the high-voltage NMOS transistor 106 is connected between the high-voltage pad 102 and the ground terminal GND. The high-voltage NMOS transistor 106 has a parasitic NPN BJT element 108, an inverting flip-flop The output of 112 is connected to the base of the BJT element 108, and the inverting flip-flop 112 turns on the BJT element 108 when the voltage VPP on the high voltage pad 102 is higher than a critical value so that the energy of the ESD on the high voltage pad is released to the ground terminal GND, thereby achieving ESD protection. Inverting flip-flop 112 includes PMOS transistor 114 connected between high voltage pad 102 and node 118, NMOS transistor 116 connected between node 118 and ground terminal GND, node 118 connected to the base of BJT element 108, resistor R1 connected to high voltage pad Between the node 102 and the node 120, the capacitor C1 is connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com