Trichlorosilane producing apparatus

A technology of trichlorosilane and a manufacturing device, which is applied in the directions of halogenated silanes, silicon compounds, halogenated silicon compounds, etc., can solve problems such as low conversion efficiency, and achieve the effects of improving conversion rate, high-efficiency heating, and high-efficiency conversion reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

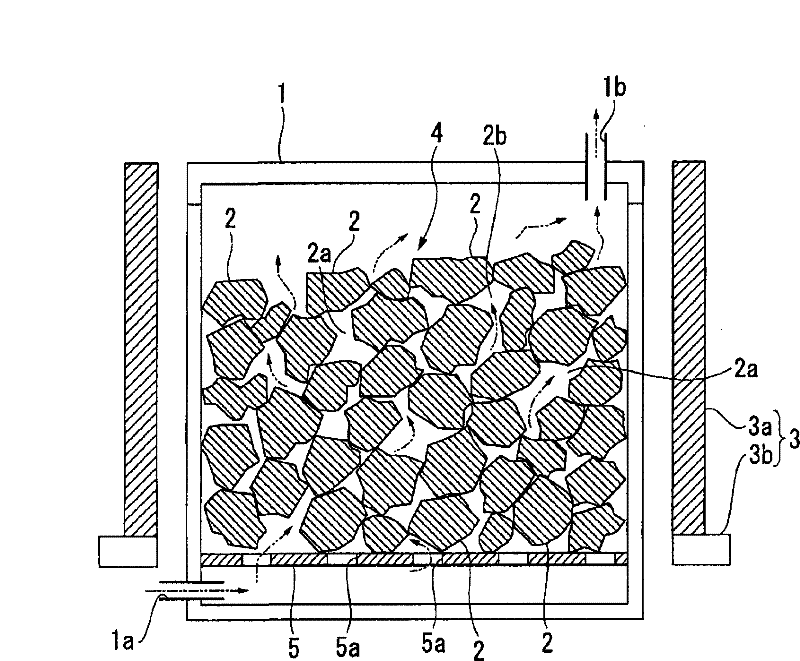

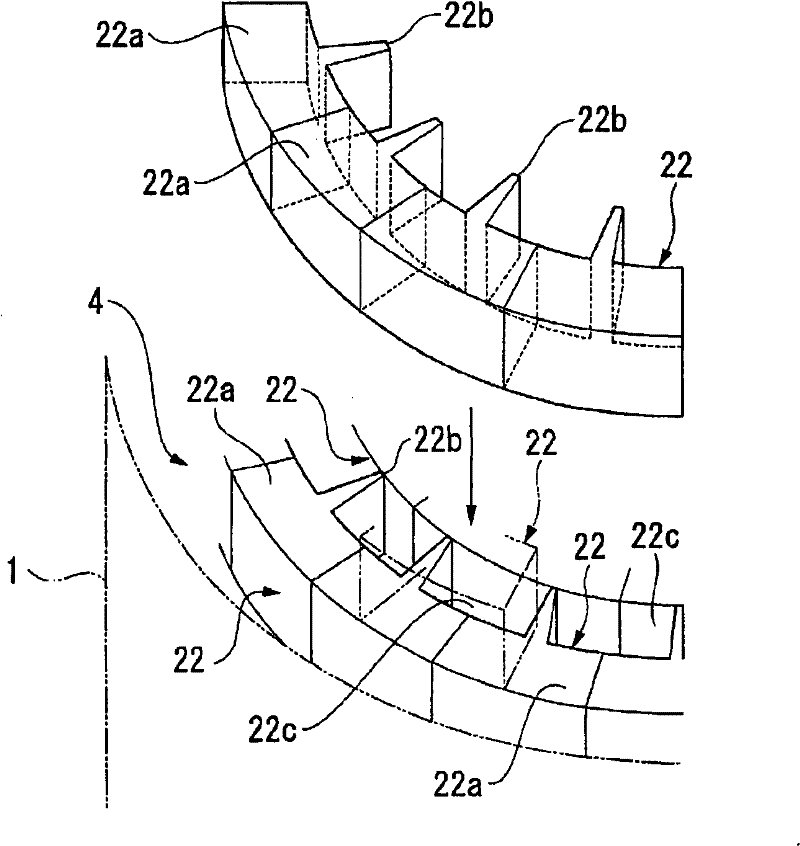

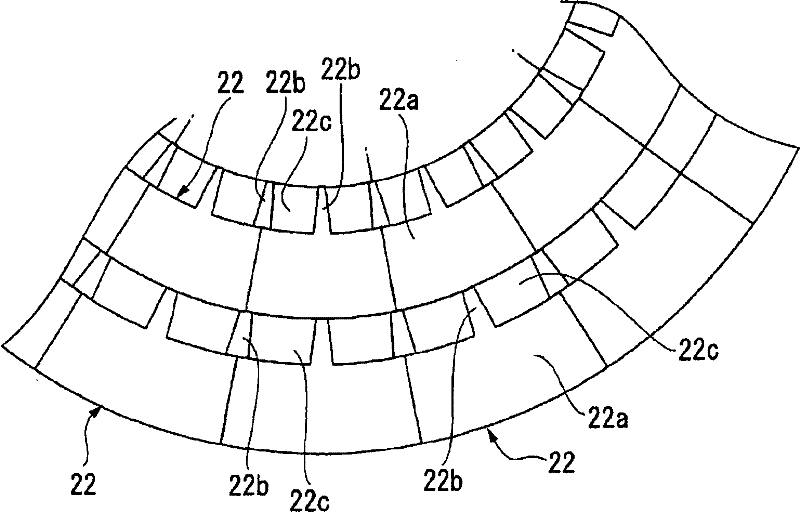

[0041] Embodiments of the trichlorosilane production apparatus of the present invention will be described below with reference to the drawings. First refer to figure 1 The first embodiment will be described.

[0042] Such as figure 1 As shown, the trichlorosilane production apparatus of the present embodiment includes: a reaction vessel 1 into which a supply gas containing silicon tetrachloride and hydrogen is supplied to generate a reaction product gas containing trichlorosilane and hydrogen chloride; a plurality of pellets 2 of a heating body filled in the reaction vessel 1, heated by radiant heat and heat conduction and having a melting point exceeding at least 1400° C.; and a heating mechanism 3 arranged around the reaction vessel 1 and utilizing radiant heat and heat conduction The heat conduction heats the pellets 2 in the reaction vessel 1 described above.

[0043] The reaction container 1 includes a gas supply port 1 a for introducing a supply gas inside, a gas outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com