Sealing arrangement of a piezoactuator for a fuel injection valve of an internal combustion engine

A piezoelectric actuator and fuel injection valve technology, which can be applied to fuel injection devices, special fuel injection devices, machines/engines, etc. problem, to achieve the effect of improving long-term stability and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

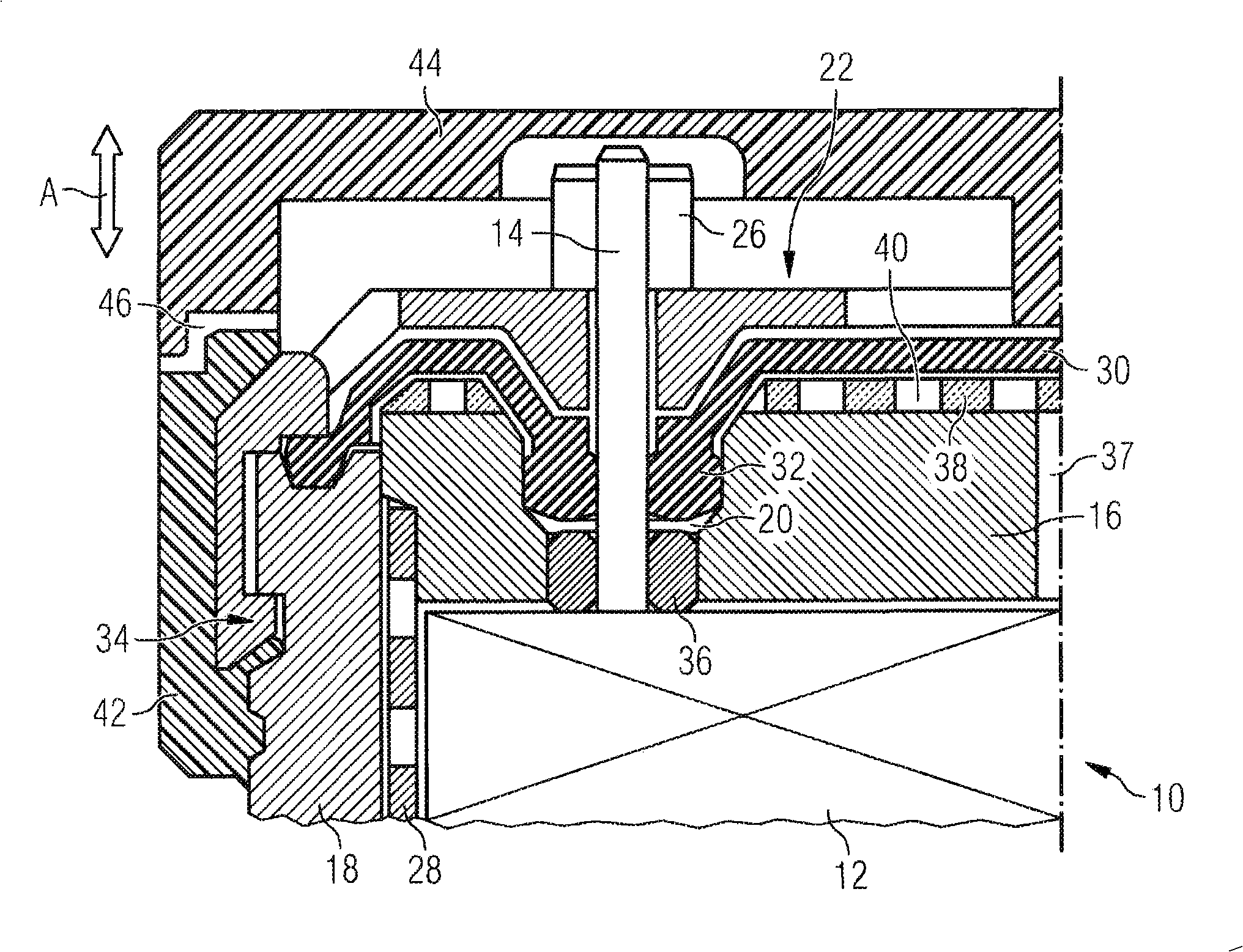

[0032] figure 1 One embodiment of a seal for a piezoelectric actuator 12 within a piezoelectric driver, generally designated 10, is shown.

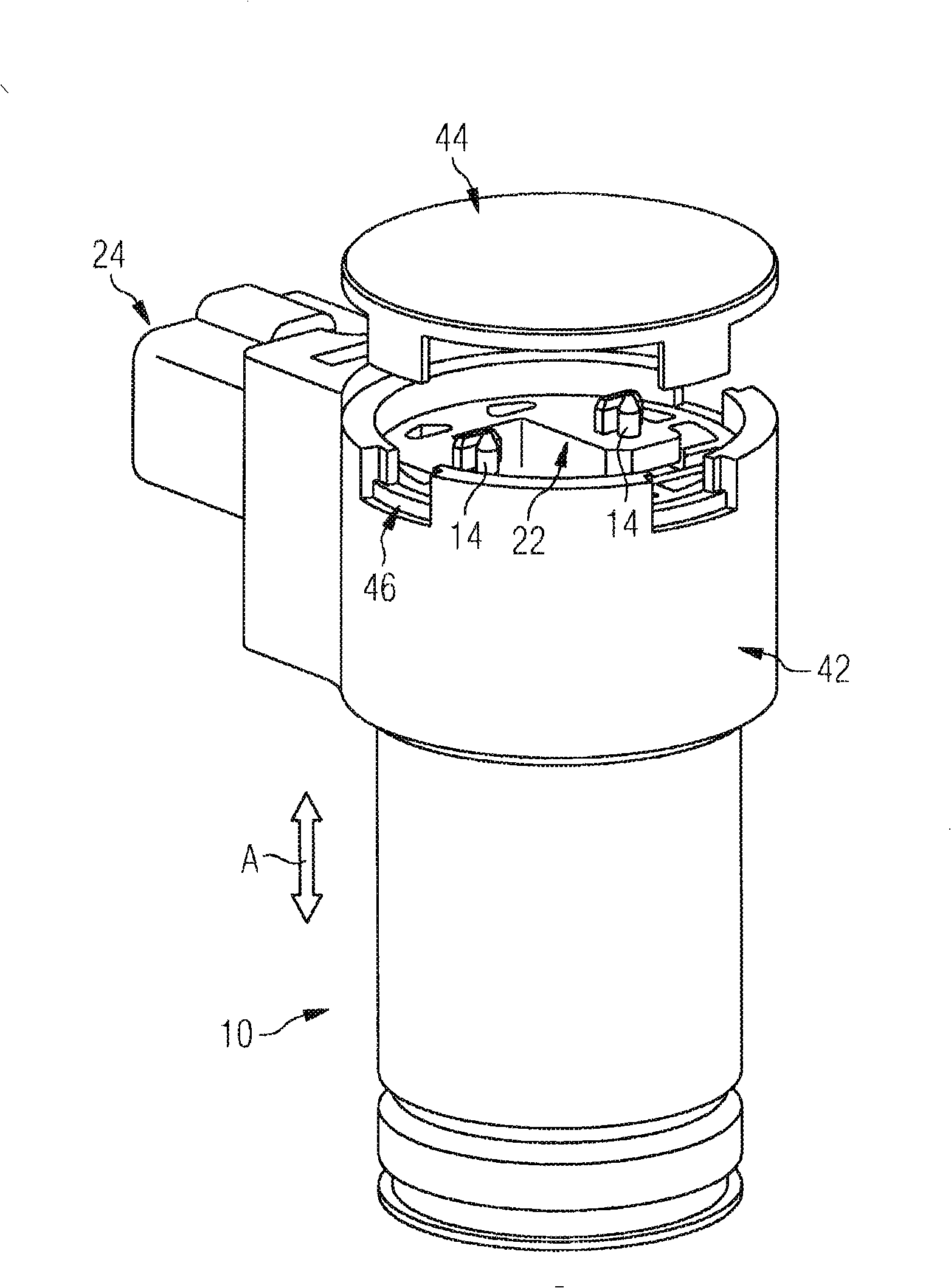

[0033] figure 2 A piezo drive 10 for actuating an injection valve of a fuel injector of an internal combustion engine (for example a diesel injector of a “common rail” injection system) is shown. In the installed state, the piezoelectric actuator 10 is shown with figure 1 The fuel injector is formed together with the injection valves arranged below the piezoelectric actuator 10 but not shown in this figure.

[0034] As far as the basic structure of the fuel injector is concerned, reference is made, for example, to known designs such as those described in DE 199 56 256 B4, DE 100 07 175 A1 and DE 10 2004 042 353 A1.

[0035] look again figure 1 , for brevity, figure 1 Only half of the (left side) of the axial section (axial A) is shown, and one of the two connecting pins 14 protruding from the piezoelectric actuator 12 can be seen from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com