Cutter mechanism of machine tool used for turning spherical workpieces

A technology of spheres and cutterheads, applied in turning equipment, turning equipment, manufacturing tools, etc., can solve the problem of inability to guarantee the rigidity and repeat positioning accuracy of the cutterhead mechanism, increase the processing difficulty and manufacturing cost of pistons and cylinders, and increase equipment operation Cost and other issues, to achieve the effect of good rigidity, low processing difficulty, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

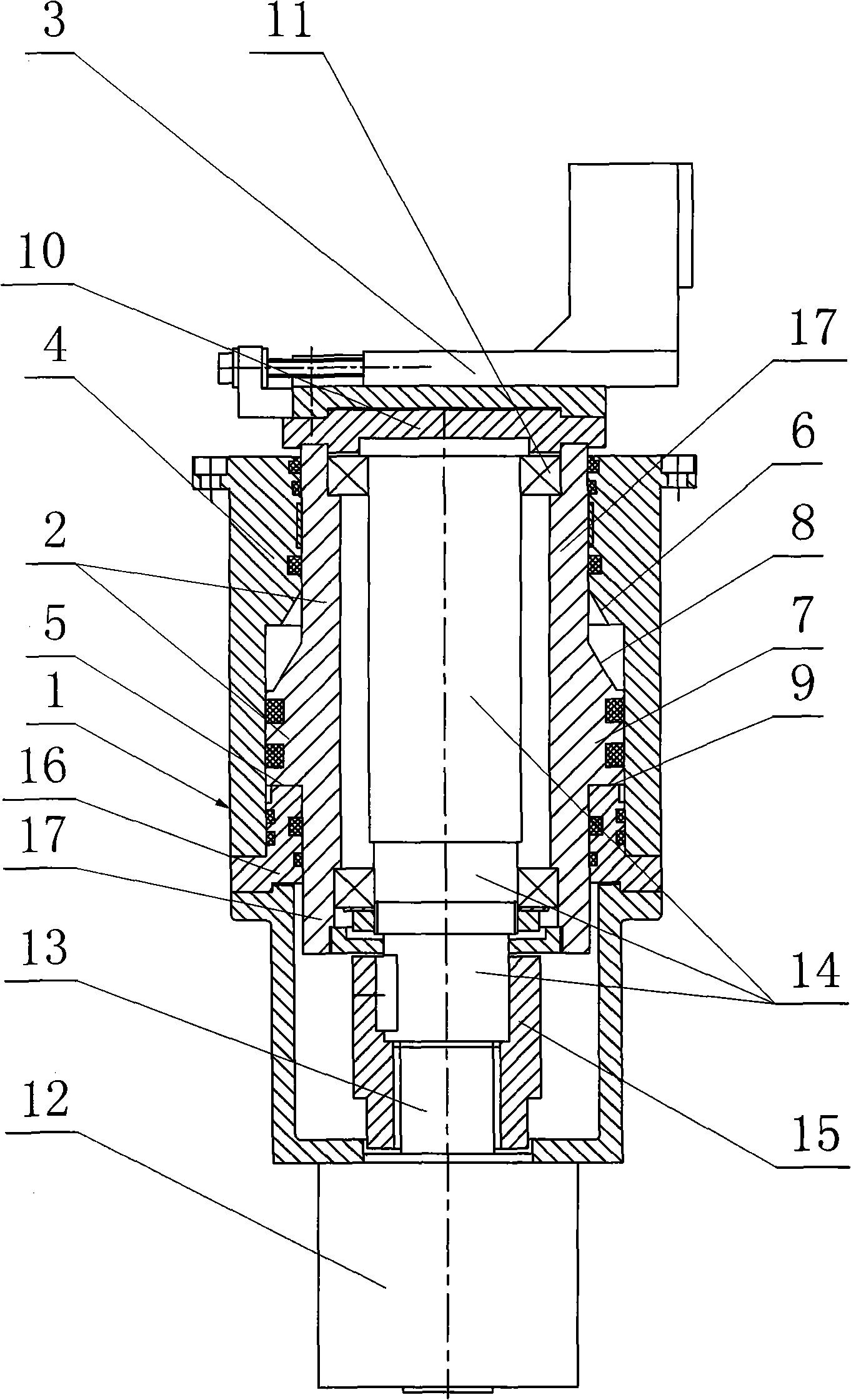

[0012] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0013] As shown in the drawings, the cutter head mechanism of the machine tool for turning spherical workpieces of the present invention includes a cutter head 3, a transmission shaft 14 driven by a rotator 12, an oil cylinder 1 and a piston 2 matched with the oil cylinder 1. A plurality of sealing rings (not marked in the figure) are provided between the piston 2 and the oil cylinder 1. The piston 2 includes a piston part 7 and a piston rod part 17. A bottom cover 16 is provided at the bottom of the oil cylinder 1, and the bottom cover 16 of the oil cylinder 1 is fixed to the head of the machine tool. A through hole penetrates through the center of the piston 2, and the transmission shaft 14 is installed in the through hole of the piston 2 through two upper and lower bearings 11. One end of the transmission shaft 14 is fixed on the cutter head 3 and the two ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com