Method of automatic welding of manual arc welding machine

A technology of automatic welding and arc welding machine, which is applied in the direction of arc welding equipment, welding equipment, paper, etc., to achieve the effect of high efficiency and simple facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

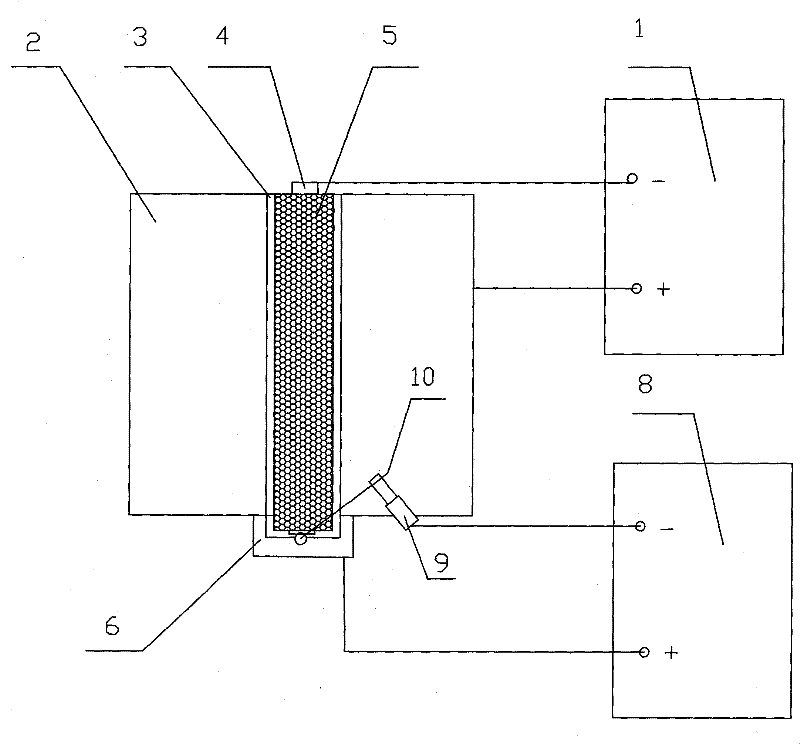

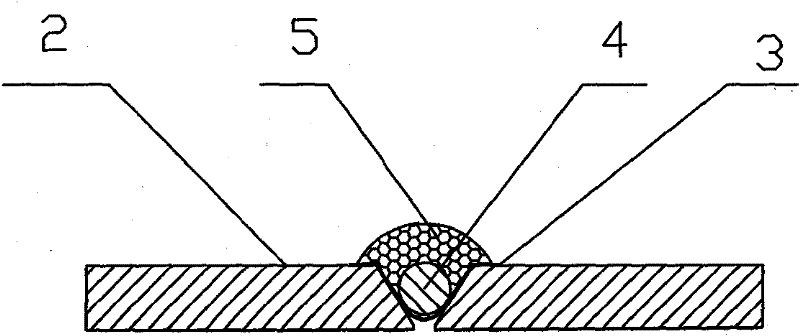

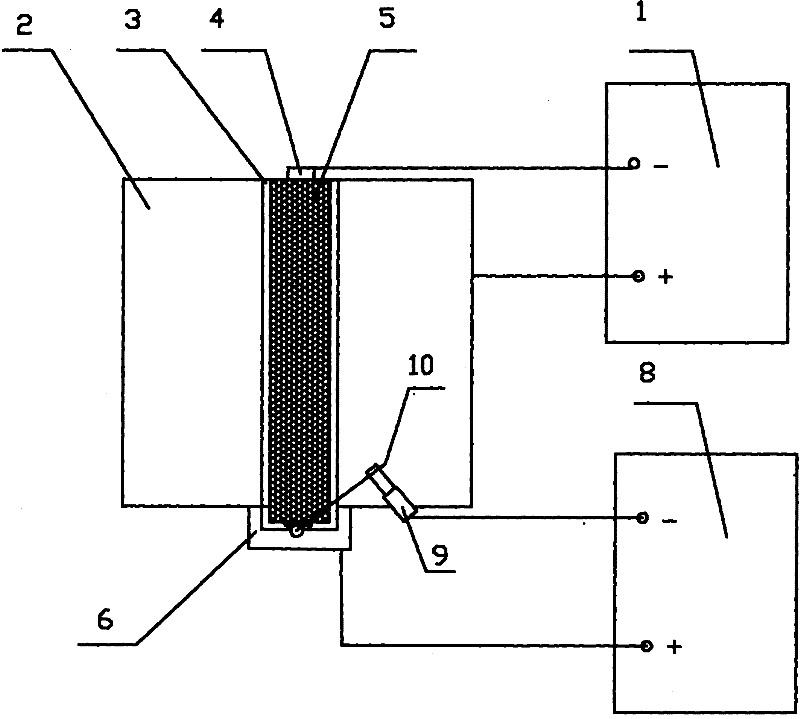

Method used

Image

Examples

specific Embodiment

[0014]

[0015] The above method has been used to successfully weld many steel structure workpieces such as steel columns and driving beams, and the effect is good, and all of them have reached the first-class welding seam standard after testing. The characteristics of welding using this method are low cost, high efficiency, large melting depth, and good double-sided forming of the weld. If it can be popularized, it will definitely bring considerable benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com