Foundation for a wind turbine

A technology for wind turbines and generators, which is applied to wind turbines, wind turbines in the same direction as the wind, engines, etc., which can solve the problems of wind turbine generator unit cost reduction and size increase, so as to reduce excavation costs and reduce formwork and the effects of simplification and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

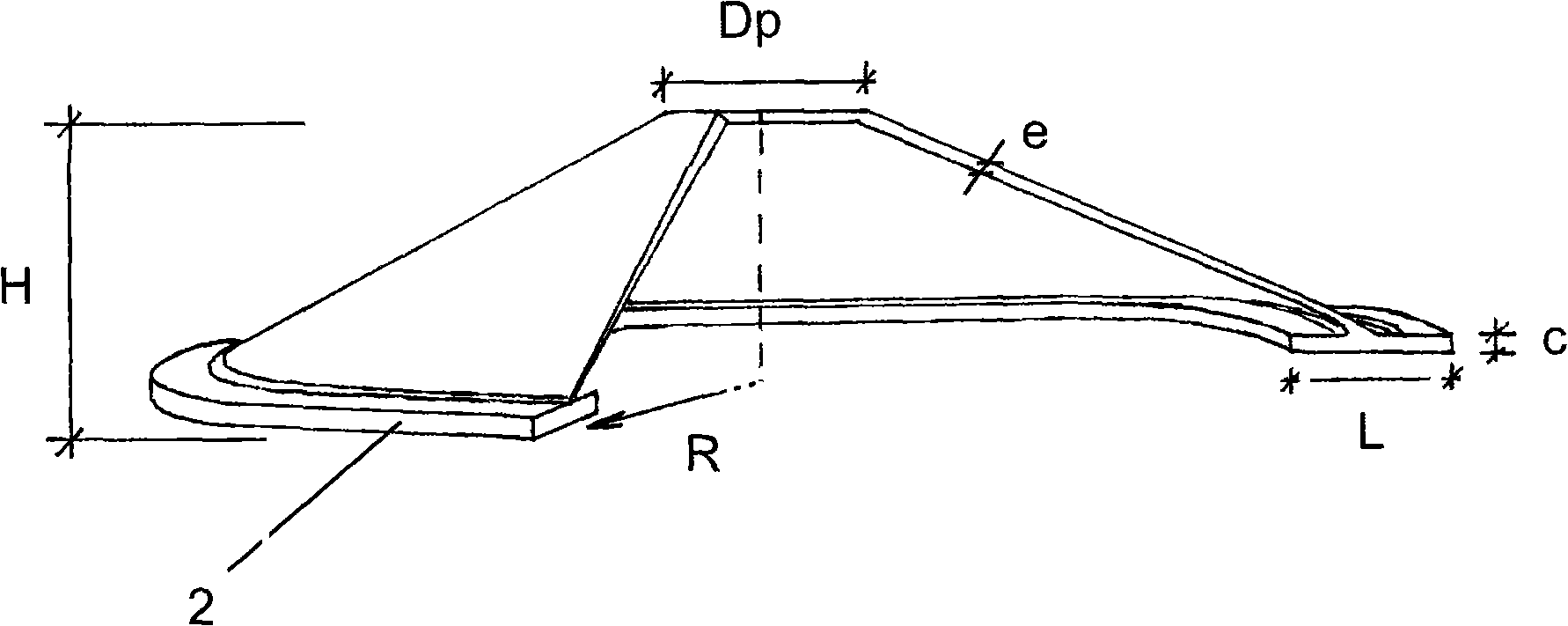

[0048] In the present invention, the cone foundation is based on a cone shape with a base plate (2) capable of bearing the stresses on the walls of the cone (1) and transferring them to the ground. Sometimes a base not shown here is used above the cone to connect the foundation to the tower, in other embodiments perhaps a concentric ring in the form of a flange is used to allow access to the hollow interior of the foundation.

[0049] In an approach similar to inertial foundations, where the radius of the cone creates inertia at its base, stresses can be smoothly transferred across the conical surface from the base of the tower to the supporting ground.

[0050] There are two main variants of this design, and one minor variant:

[0051] ◆Filled conical foundations involved in the preferred embodiment of the invention. Since the soil is not excavated from the inside, the conical surface wall (1) rests on this soil, so less stress occurs on the wall because there is no local be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com