Automatic detection method and device of wall thickness of perforating bullet energy concentrating cover

An automatic detection and energy-gathering cover technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effect of improving measurement accuracy, high measurement accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

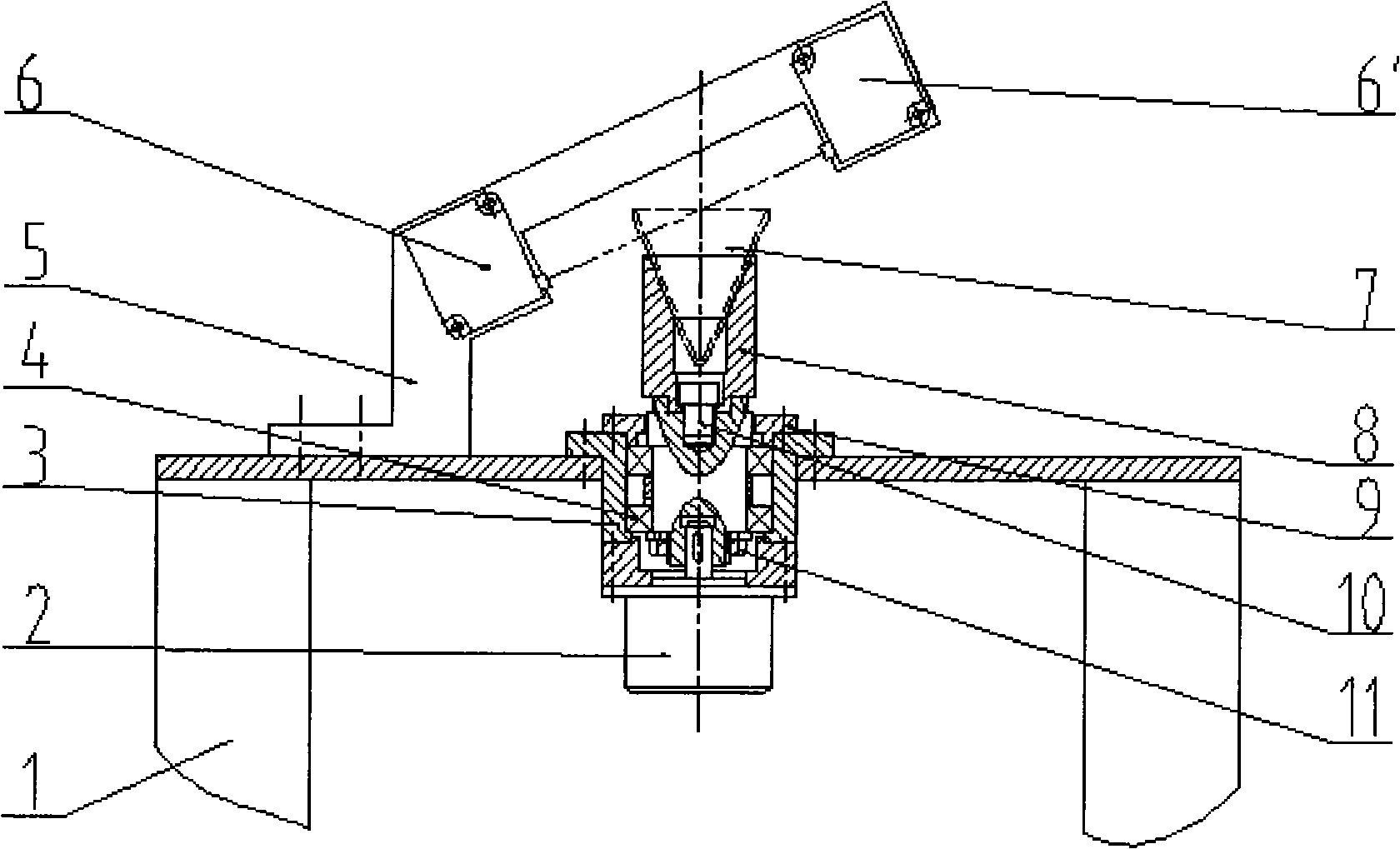

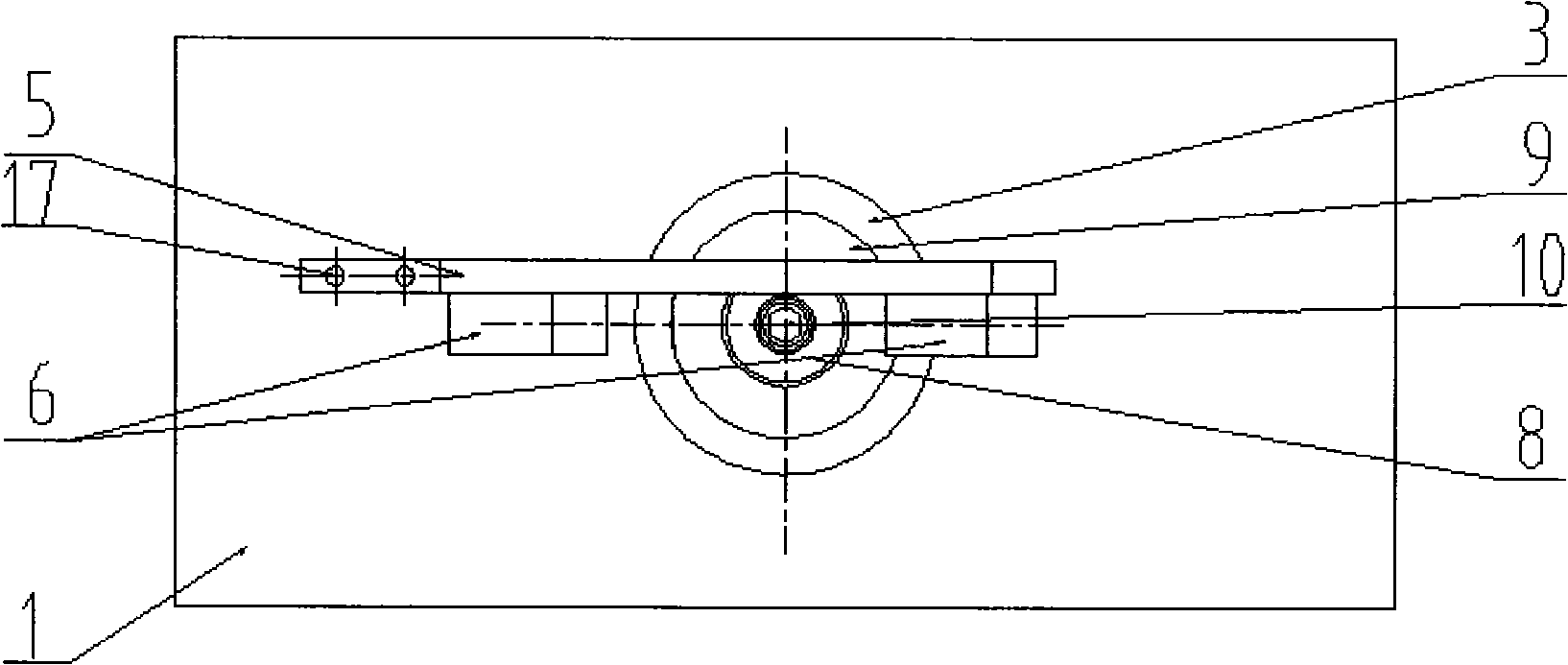

[0008] The specific embodiment of the present invention is described in detail in conjunction with the technical scheme and the accompanying drawings: the wall thickness measurement is performed on the automatic detection device of the perforating bullet energy-collecting cover controlled by an external PLC; Ensure that the axis of the energy-gathering cover is coaxial with the axis of the measuring cup and perpendicular to the worktable; start the stepping motor 2, and the stepping motor 2 drives the main shaft 10 and the measuring cup 8 to rotate, and the energy-gathering cover 7 rotates at a speed of 40 revolutions per minute; The CCD left laser length measuring sensor 6 and right laser length measuring sensor 6' placed on both sides of the energy gathering cover transmit signals to the same point of the energy gathering cover at the same time and receive the return signal at the same time. The outer wall of the cover emits signals, and the right laser length-measuring senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com