Method for detecting percentage of medicinal powder of flux-cored wire

A technology of flux-cored welding wire and detection method, which is applied in measurement devices, analytical materials, linear/angular velocity measurement, etc., to achieve accurate and effective detection results, improve manufacturing capacity and production management level, and reduce raw material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Flux-cored welding wire is processed by a welding wire forming machine. The forming machine first pulls the steel strip into a hollow welding wire, and then adds powder to the hollow welding wire to make it a flux-cored welding wire, and then coils it to take up the wire.

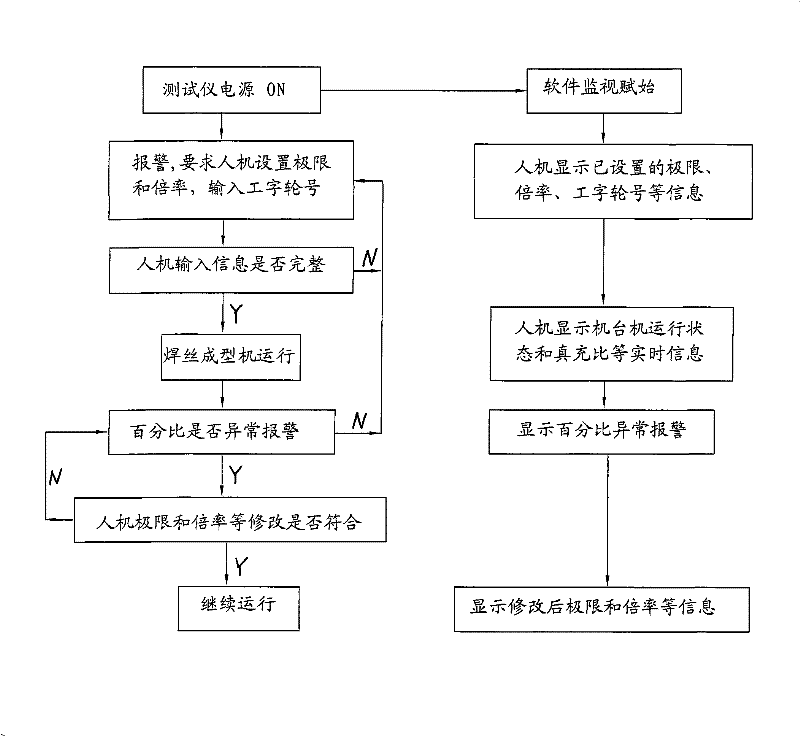

[0028] as attached figure 1 As shown, a method for detecting the powder percentage of flux-cored welding wire, after turning on the power of the tester, includes the following steps:

[0029] (1) Through man-machine preset limit and initial value of magnification, and input information such as I-shaped wheel number, job number, steel strip thickness and detection range, etc.,

[0030] (2) Start the operation of the welding wire forming machine;

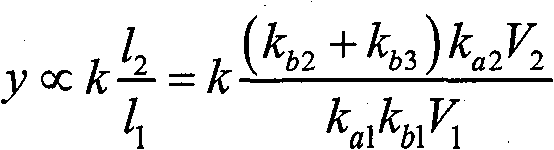

[0031] (3) The speed V of the hollow welding wire before dosing powder is controlled by the transmission motor frequency converter 1 and the speed V of the flux-cored wire after adding powder 2 collected separately;

[0032] (4), the speed analog signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com