Exhaust gas purification catalyst, and catalytic honey-comb structure for exhaust gas purification

A honeycomb catalyst and exhaust gas purification technology, applied in catalyst activation/preparation, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as lack of teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

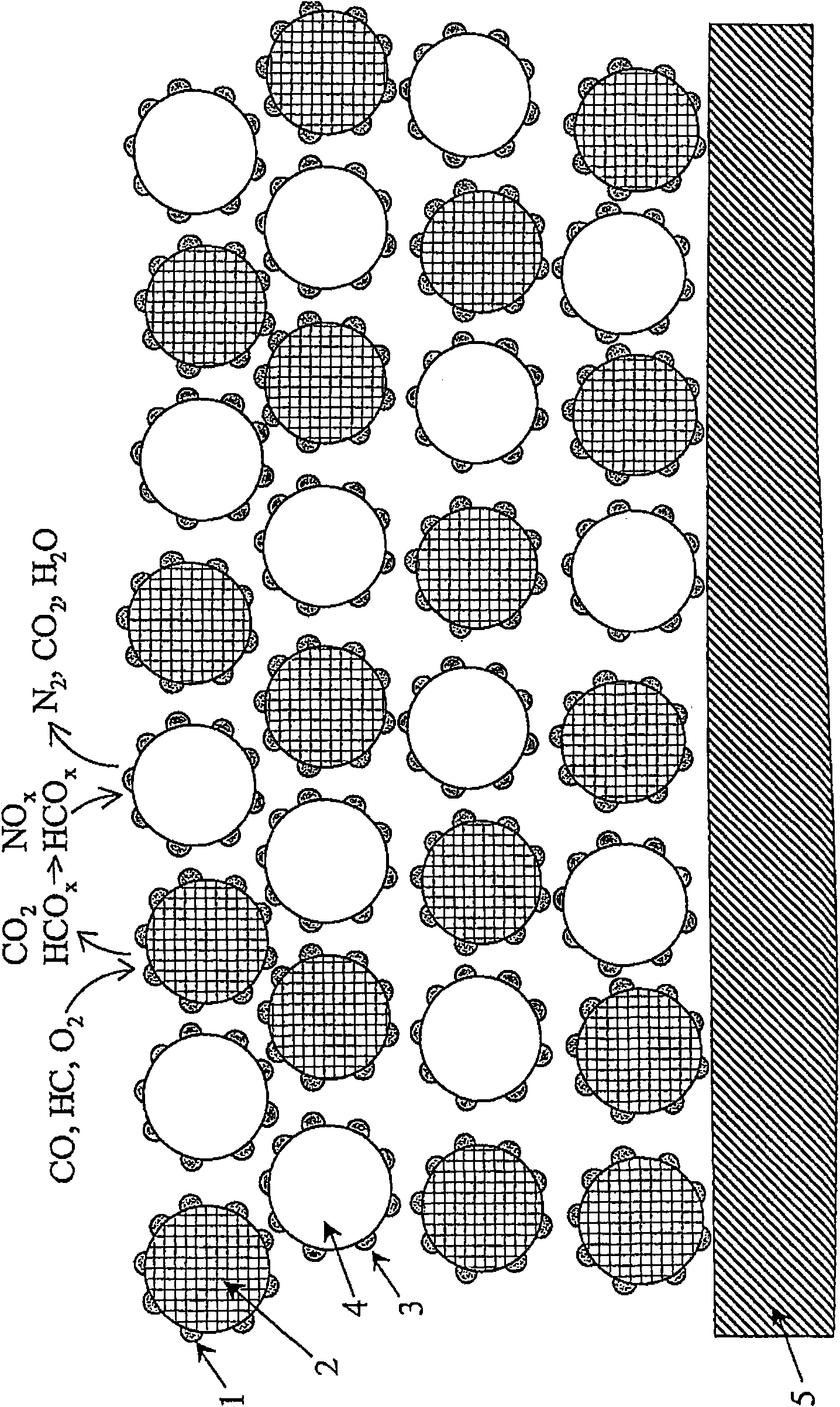

[0054] M(Co 1-y Fe y )O 3-δ composite oxides.

[0055] Carbonates are used as raw materials for Sr and Ba, and oxides are used as raw materials for Co and Fe. The above-mentioned raw materials were weighed at a predetermined molar ratio, added to isopropanol (dispersion medium), and wet-mixed while pulverizing using a ball mill to obtain a slurry. The solid content was separated from the slurry using a suction filter, and dried at about 120° C. for 1 hour. Next, after crushing the obtained dry solid, it fired in the air at 950 degreeC for 5 hours using an electric furnace, and obtained the fired thing of porous block shape. After crushing the burnt product, it was dry-pulverized using an automatic mortar to prepare M(Co 1-y Fe y )O 3-δ composite oxides. The average particle size of the pulverized oxide is 1.2μm, and the specific surface area is 2.2m 2 / g. Regarding the composition, although the added amount at the time of manufacture was used, it was confirmed by sep...

Embodiment 2

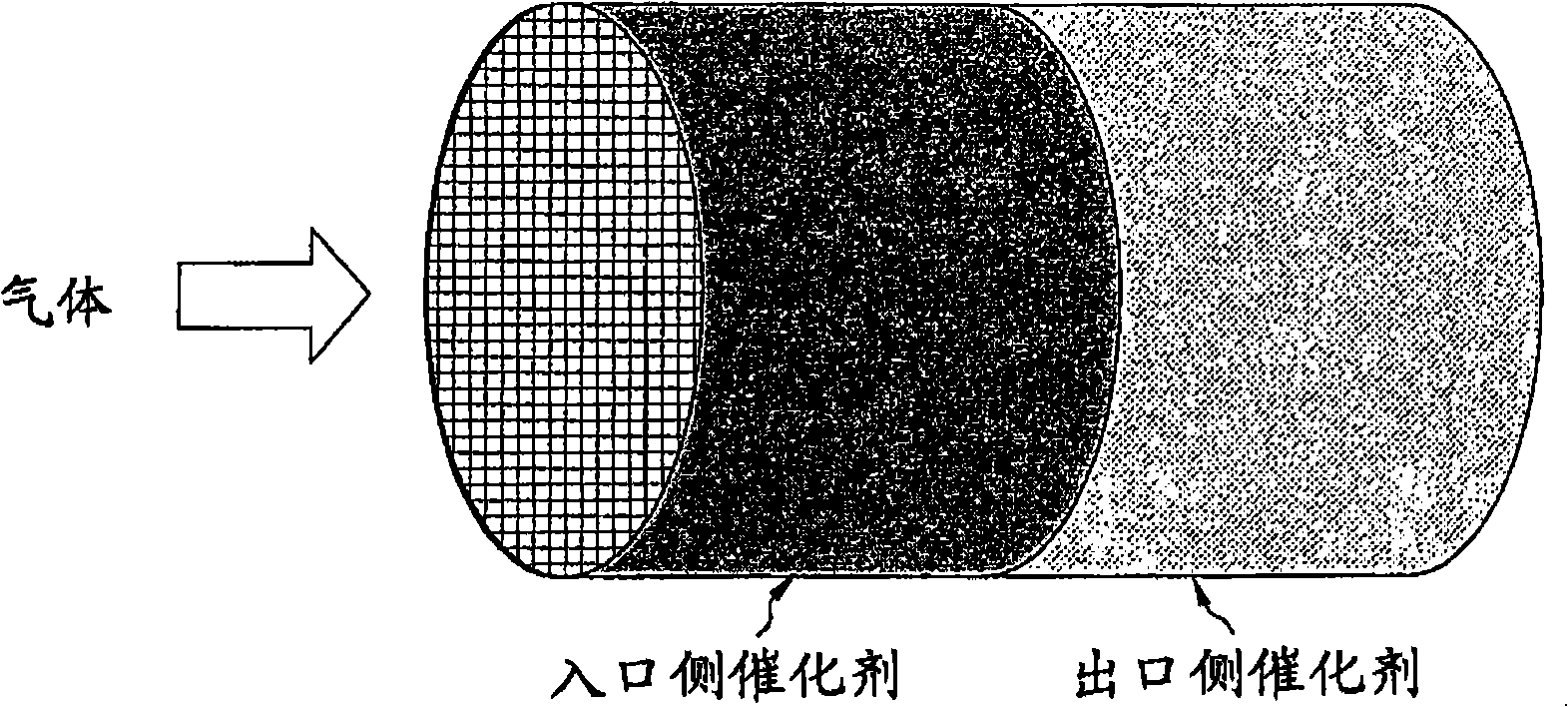

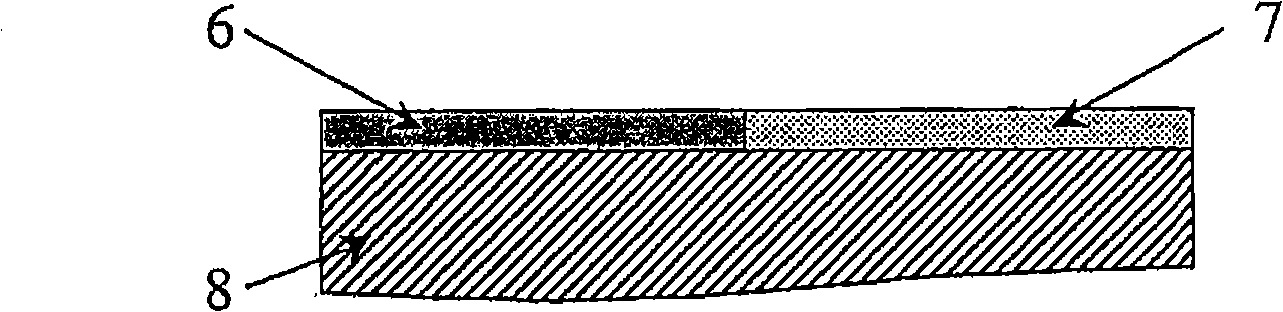

[0076] In the SrCoO produced by the same method as in Example 1 3-δ On the composite oxide, Pd with a loading amount of 0.6 parts by mass was loaded by the same method as in Example 1, and Pd-loaded SrCoO was prepared. 3-δ Composite oxide (A). In addition, Rh was supported in an amount of 0.5 parts by mass on activated alumina in the same manner as in Example 1 to prepare Rh-supported activated alumina (B). The catalysts were prepared by changing the mixing ratio of (A) and (B) as shown in Table 4. As shown in Figure 2 (a) and Figure 2 (b), the catalyst prepared above is divided into the gas inlet side and the gas outlet side, and is washed on the ceramic honeycomb and the stainless steel honeycomb by the same method as in Example 1 to make a honeycomb catalyst structure. In addition, the concentration of the slurry is doubled, as shown in Figure 3(a), Figure 3(b), and Figure 3(c), the catalyst (A) is washed first, and the gas inlet side is thickened during the drying proce...

Embodiment 3

[0084] As shown in Table 6, in the M(Co obtained by the same method as in Example 1) 1-y Fe y )O 3-δ On the composite oxide, the same method as in Example 1 was used to load Pd and Rh in an amount of 0.6 parts by mass, and M(Co) loaded with precious metals was prepared. 1-y Fe y )O 3-δ Composite oxide (A). In addition, Pd and Rh were supported in an amount of 0.5 parts by mass on activated alumina in the same manner as in Example 1 to prepare a noble metal-supported activated alumina (B). The catalyst obtained above is divided into the gas inlet side and the gas outlet side as shown in Figure 4 (a) and Figure 4 (b), respectively, and the same method as in Example 1 is used to wash and coat ceramic honeycombs and stainless steel honeycombs to form Honeycomb catalyst structure. The evaluation method of the catalytic performance of the honeycomb catalyst structure is the same as in Example 1. The evaluation results are shown in Table 7.

[0085] Table 6

[0086]

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com