Crank assembly method of two-stroke engine

An assembly method and engine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of large axial movement of the crankshaft, and achieve the effect of reducing failure, reducing the possibility of failure, and good lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

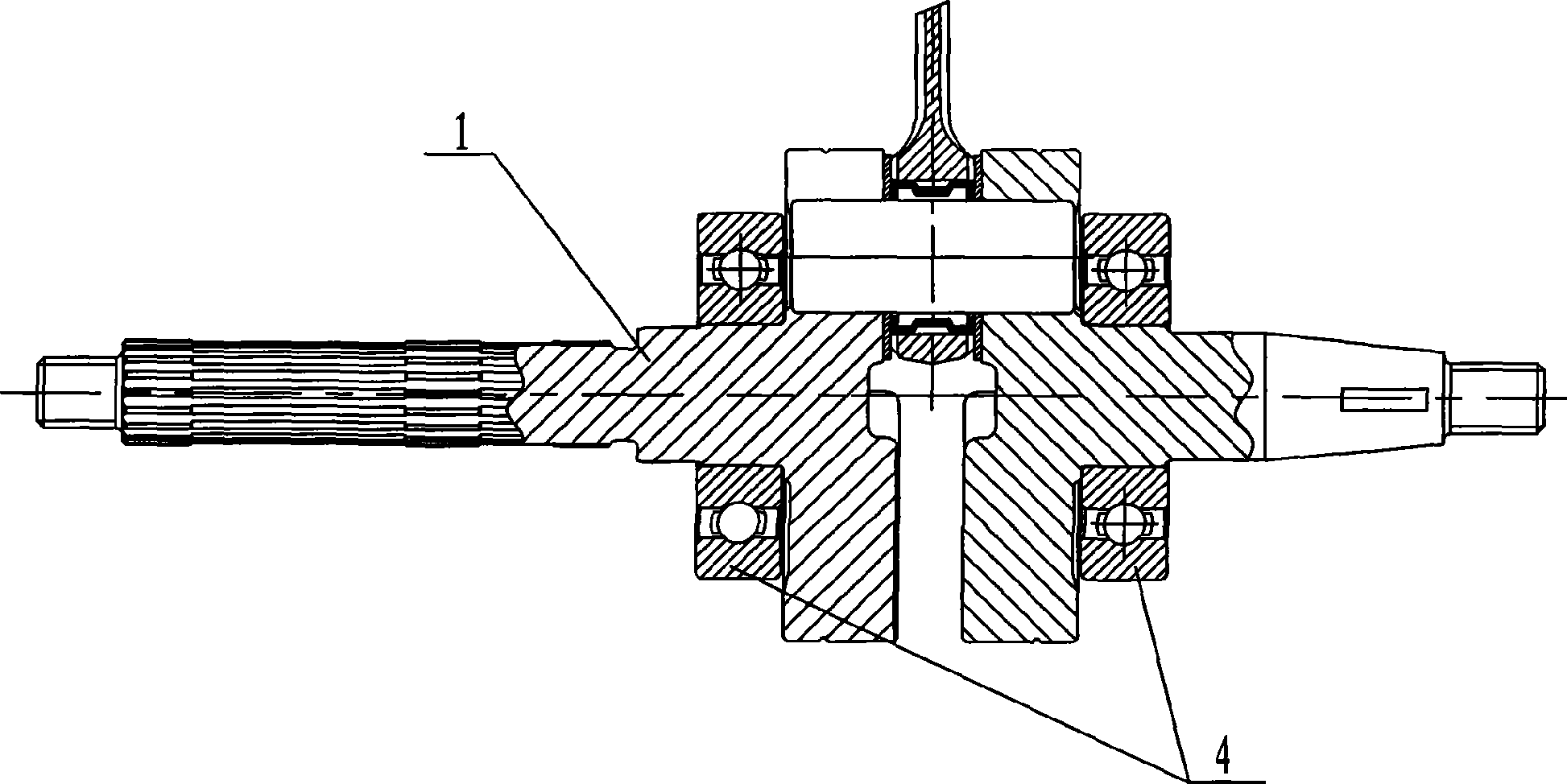

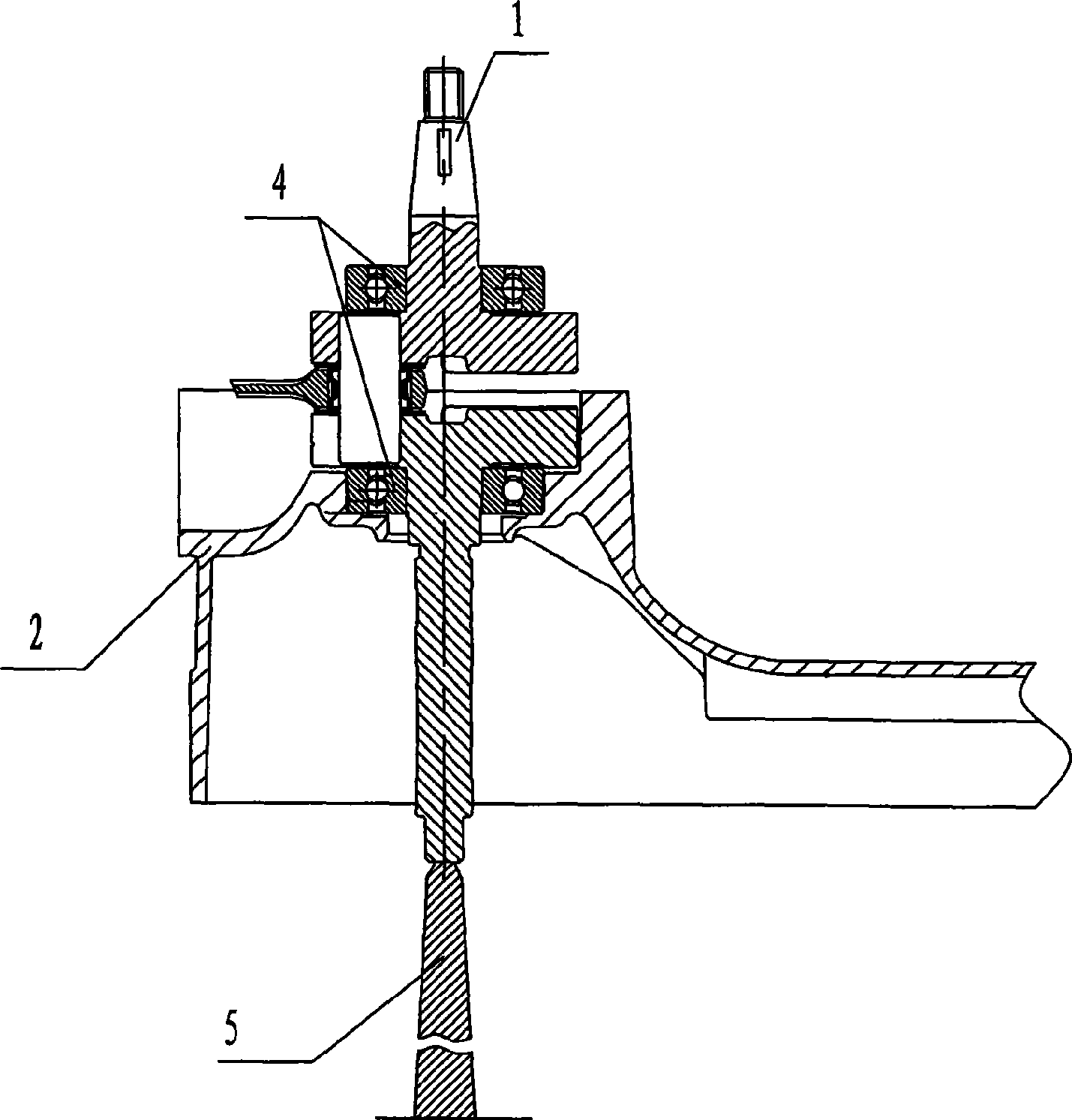

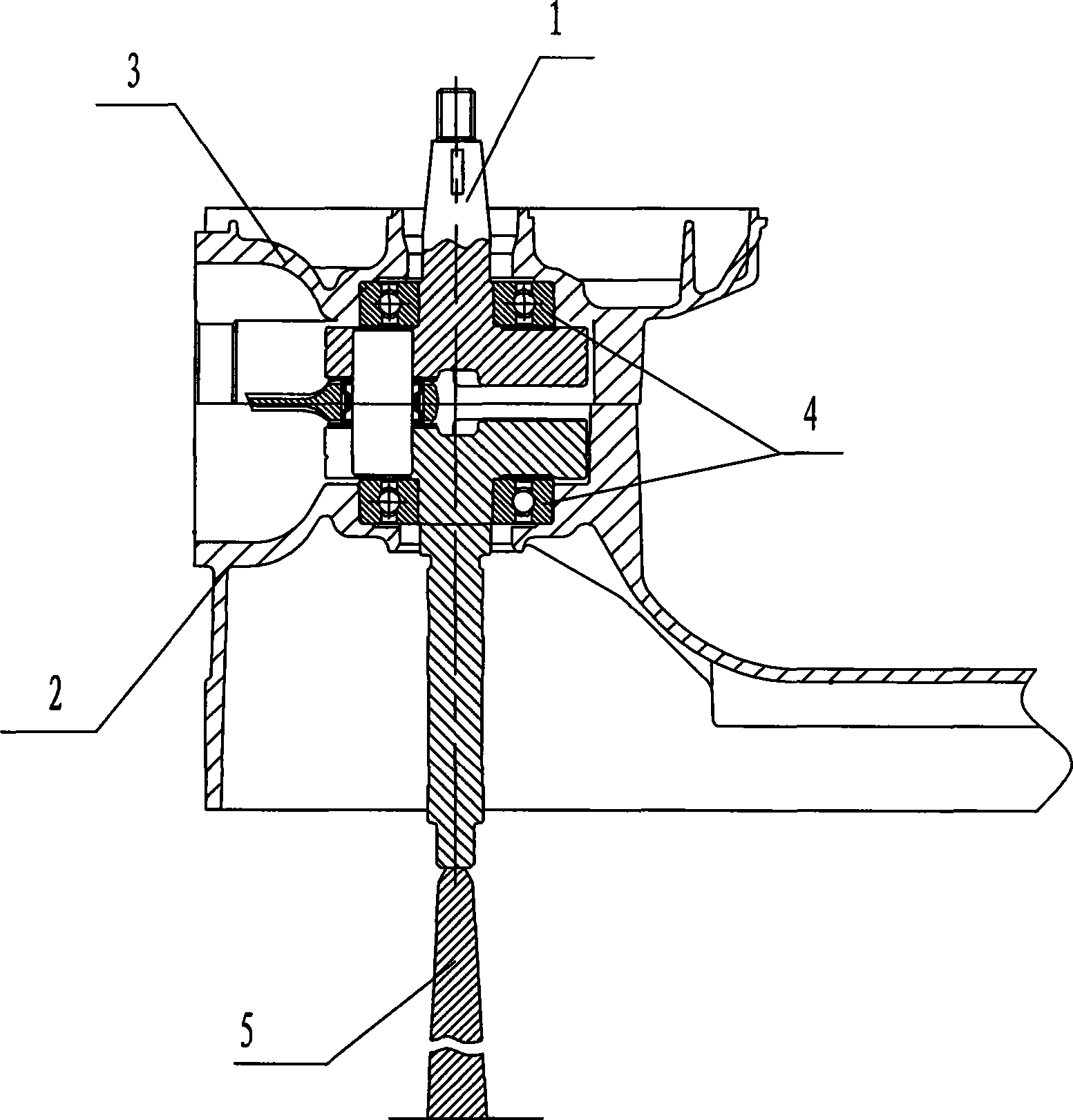

[0033] Embodiment 1: as Figure 1 to Figure 4 As shown, a two-stroke engine crankshaft assembly method is characterized in that the method is carried out as follows: (1) press two bearings 4 onto the left and right crankshaft handles respectively, so that the inner ring of the bearing and the crankshaft are in an interference fit (2) Assemble the crankshaft 1 to the left crankcase 2 and the right crankcase 3, so that the outer rings of the left and right bearings on the crankshaft are in interference fit with the left and right crankcases respectively.

[0034] Assemble in step (2) as follows:

[0035] a. After heating the bearing hole of the left crankcase 2 to 110°C, assemble the crankshaft 1 to the left crankcase 2 within 2 seconds;

[0036] b. After heating the bearing hole of the right crankcase 3 to 110°C, assemble the right crankcase 3 to the left crankcase 2 within 2 seconds.

[0037] In steps a and b, the bearing hole is heated to 110° C. by partially energizing the...

Embodiment 2

[0041] Embodiment 2: as image 3 As shown, a two-stroke engine includes a left crankcase 2 and a right crankcase 3, the crankshaft 1 arranged on the left and right crankcases 2, 3 and the crankshaft 1 arranged on the crankcase 1 Two bearings 4, characterized in that: the inner ring of the bearing 4 is interference fit with the crankshaft 1, and the outer ring of the bearing 4 is interference fit with the left and right crankcases 2, 3, and the tolerance range 0.017-0.047mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com