Yarn end retrieving apparatus

A technology for a spinning device and a bobbin, which is applied in the field of spinning devices, can solve problems such as poor operation and inability to correctly capture the yarn end, and achieve the effect of simple production change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

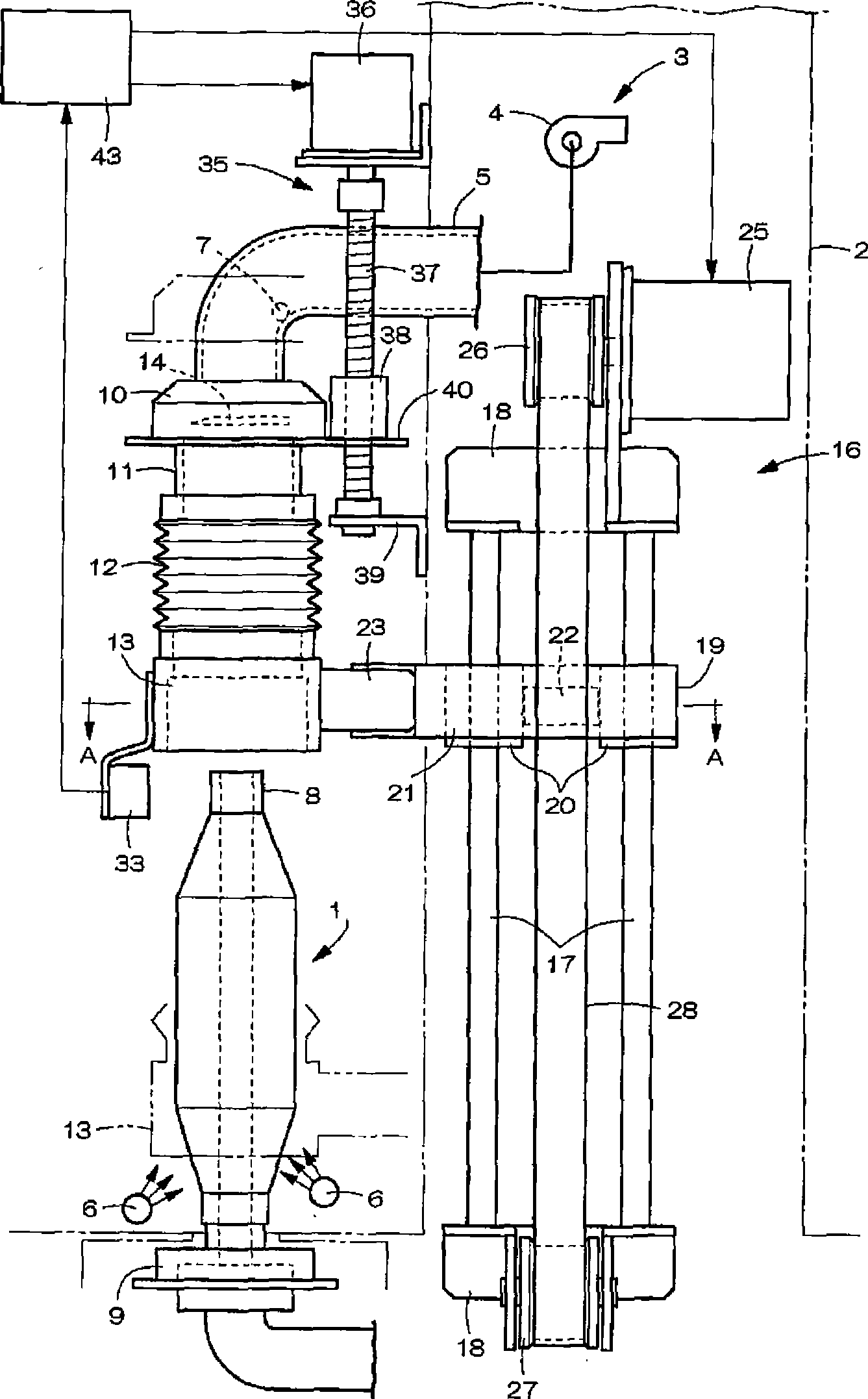

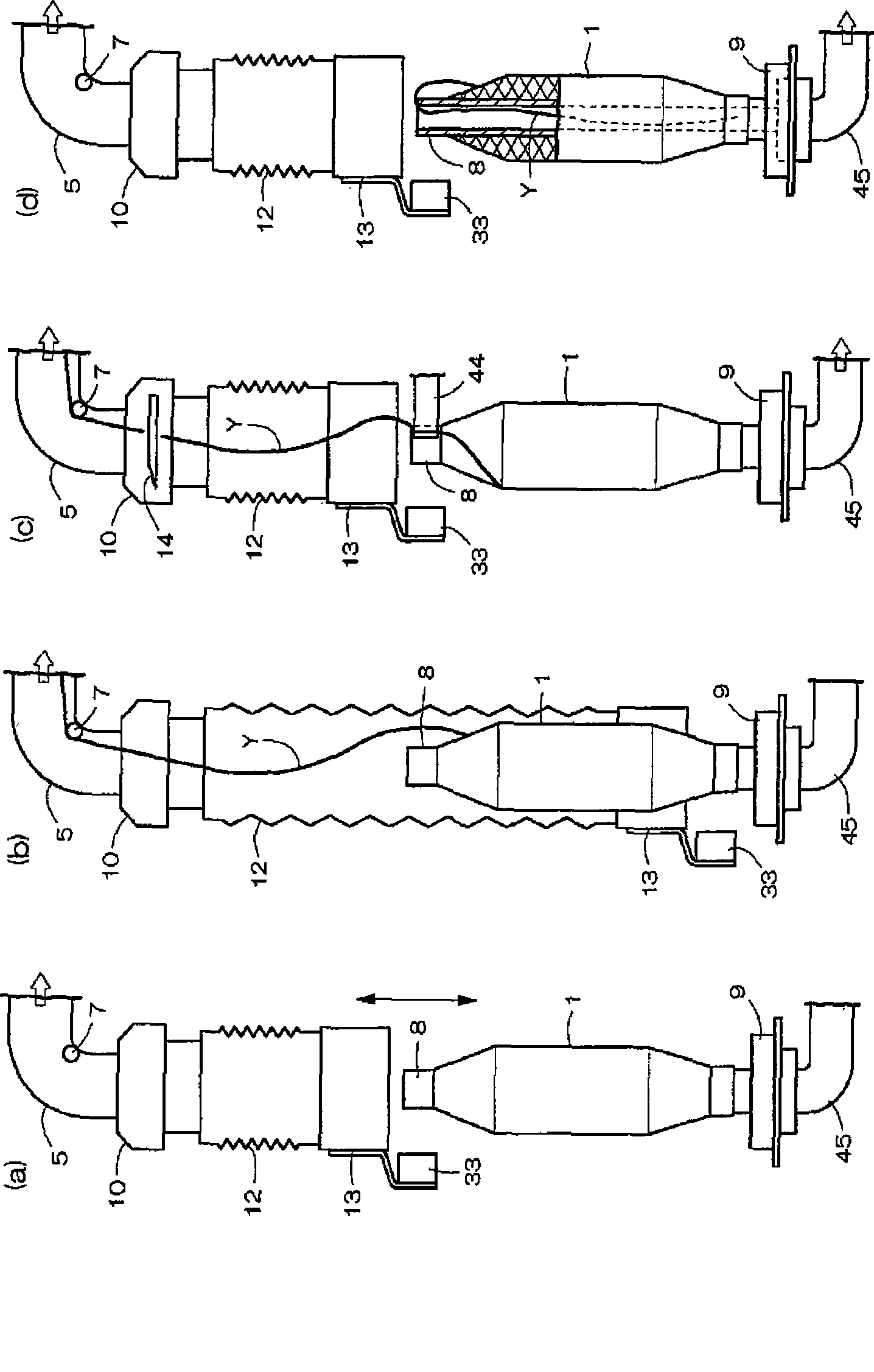

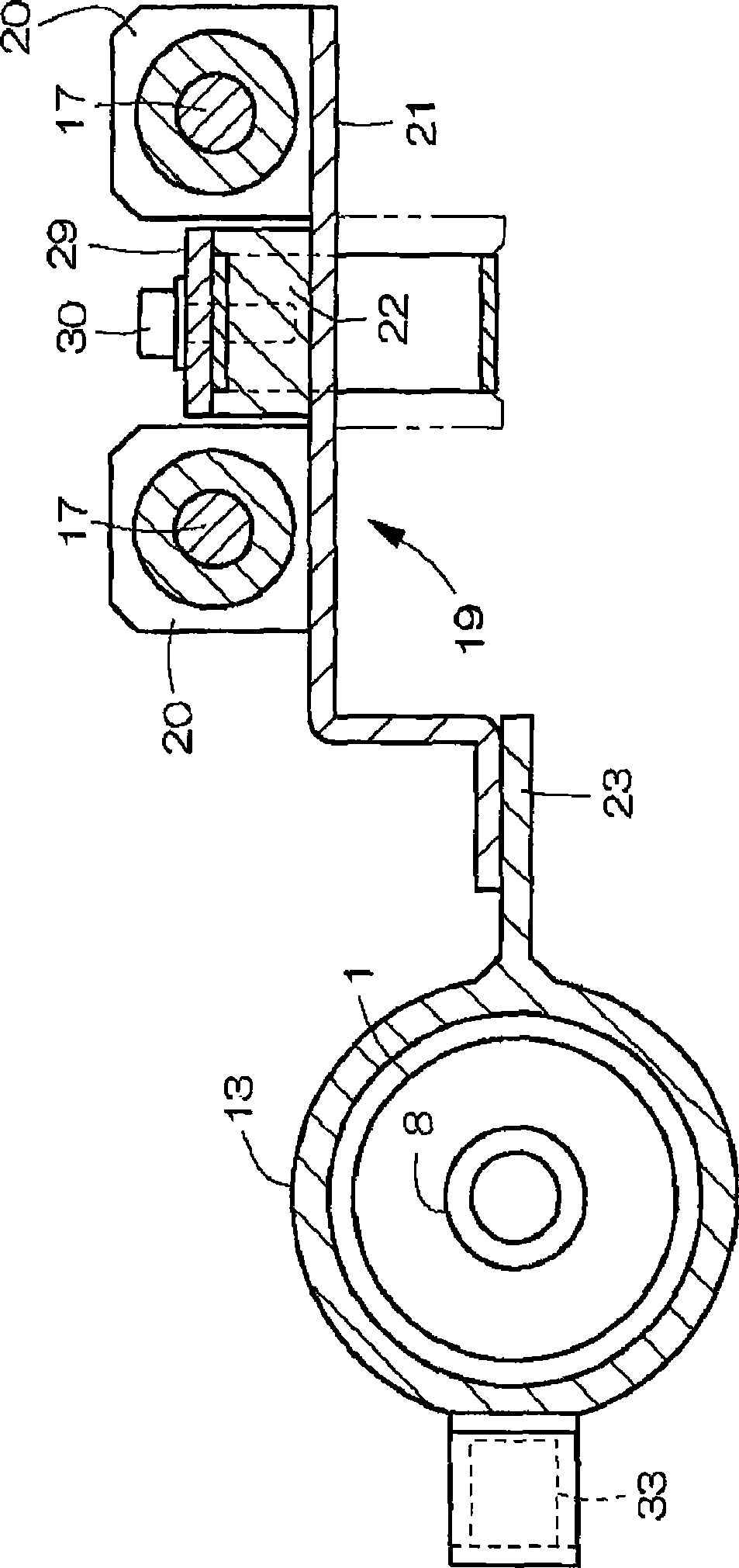

[0023] Figure 1 to Figure 3 An example of the spin-in device according to the present invention is shown. exist figure 1 Among them, the spin-in device has a vertically elongated body 2 arranged opposite to the conveying path of the bobbin 1, and a yarn detaching device 3 is arranged from the front upper part of the body 2 to the inside of the body. The yarn detaching device 3 is composed of a fan 4 for generating a suction air flow, a suction pipe 5 connected to the suction port of the fan 4, a pair of nozzles 6 for blowing compressed air toward the bobbin 1, and the like. The suction pipe 5 disposed on the front upper portion of the machine body 2 can be bent into an inverted L-shape, and the yarn detection sensor 7 is disposed at an inner corner of the bent portion. The bobbin 1 has a winding core 8 with upper and lower ends open, and the lower end of the winding core 8 is supported by a transport tray 9 provided along the transport path.

[0024] At the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com