Damper of furniture

A damper and furniture technology, which is applied in the field of furniture dampers, can solve the problems of reduced service life, easy breakage at the end, small area, etc., and achieve the effects of reducing installation steps, avoiding cracking, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

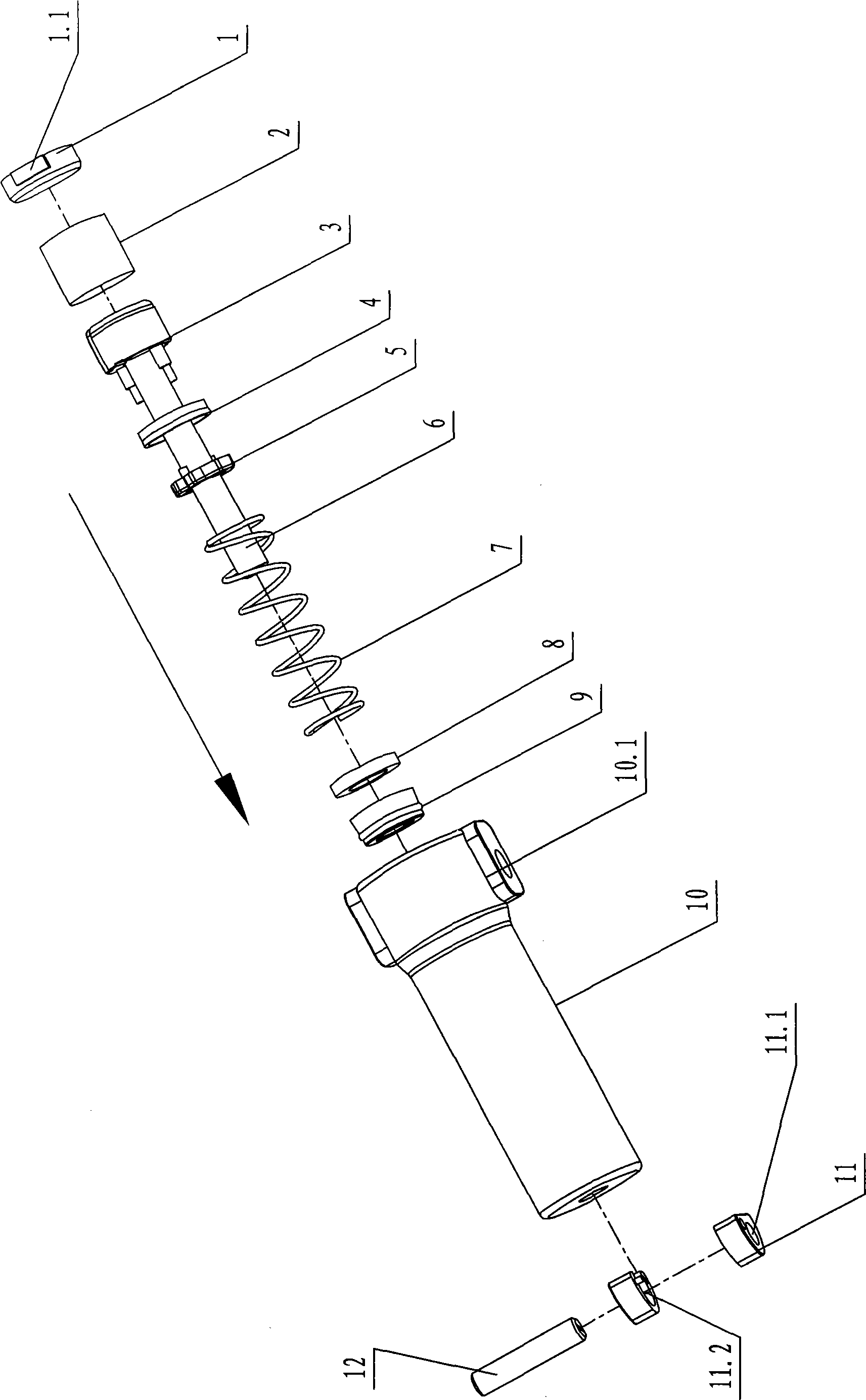

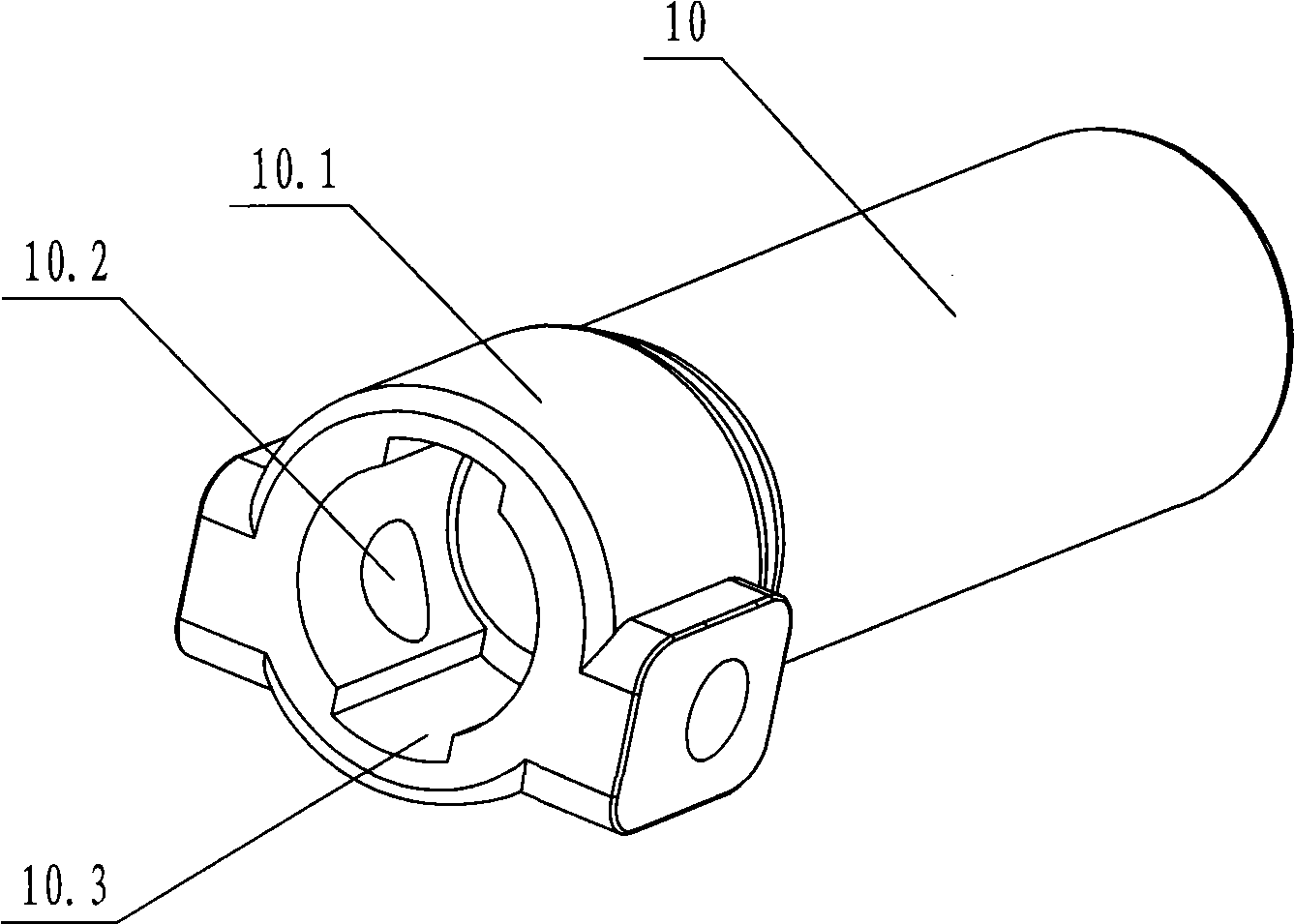

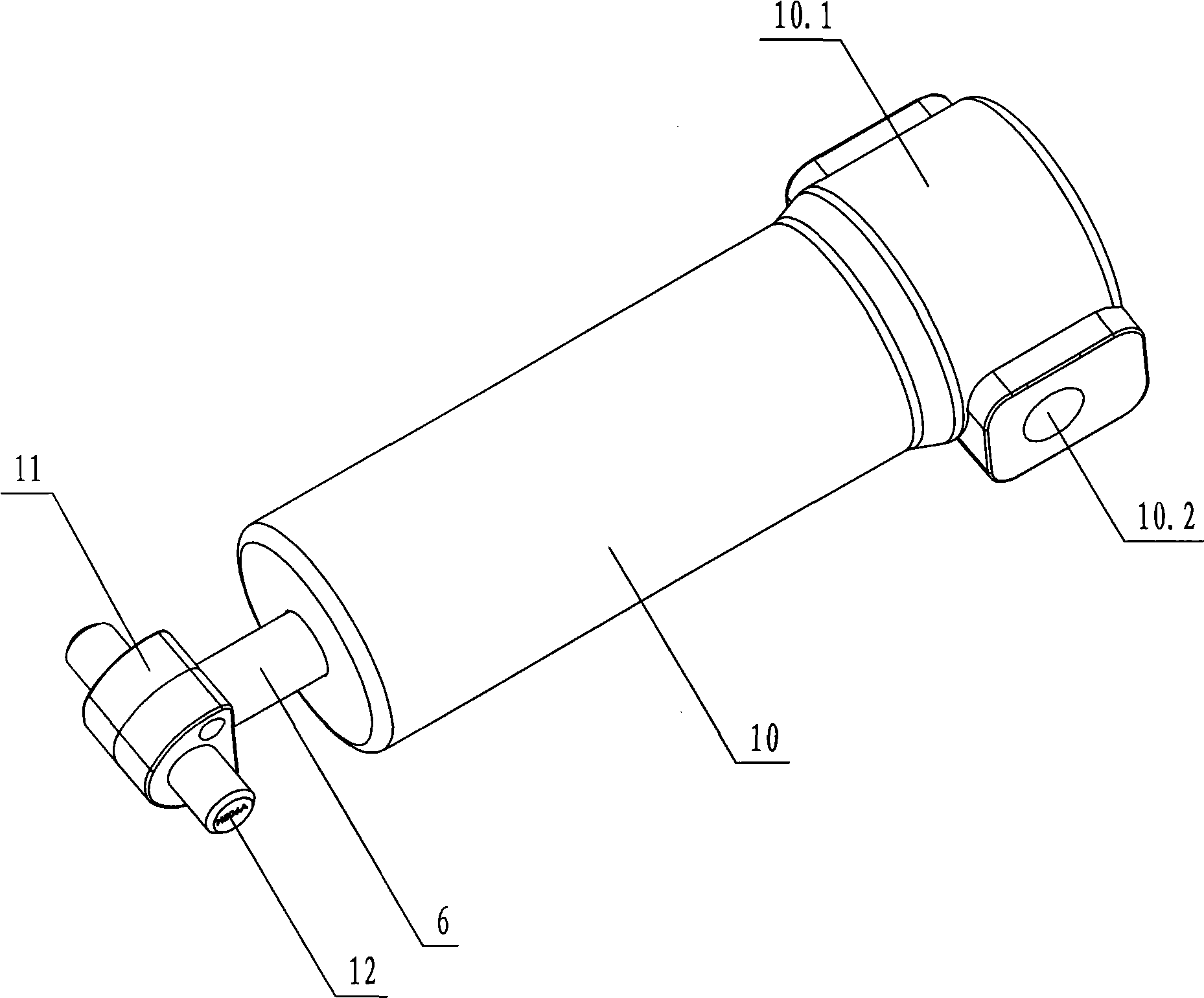

[0023] see Figure 1-Figure 8 , the damper of this furniture includes hinge fixing seat 13, hinge arm 15 and rocker arm 14, one end of the damper is connected with the hinge arm, and the other end is connected with the rocker arm, see Figure 8 . The damper includes a piston 3, a damping plate 4 and a limiting plate 5 arranged in the cylinder body 10, and one end of the piston rod 6 extends into the cylinder body, passes through the limiting plate and the damping plate, and connects with the piston. There is one or more first overflow grooves 3.1 on the outside of the piston, and an annular step 4.1 is provided on the side of the damping plate facing the limit plate, and a certain oil clearance gap is maintained between the piston, damping plate, limit plate and the inner wall of the cylinder ,See Figure 7 . The front end of the cylinder body 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com