Diaphragm cylinder device

A technology of cylinder device and diaphragm, which is applied in the direction of fluid pressure actuating device, etc., can solve the problems of pump device discharge accuracy drop, linearity drop, diaphragm 7 aging, etc., and achieve the effect of improving action characteristics and ensuring linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0059] (the whole frame)

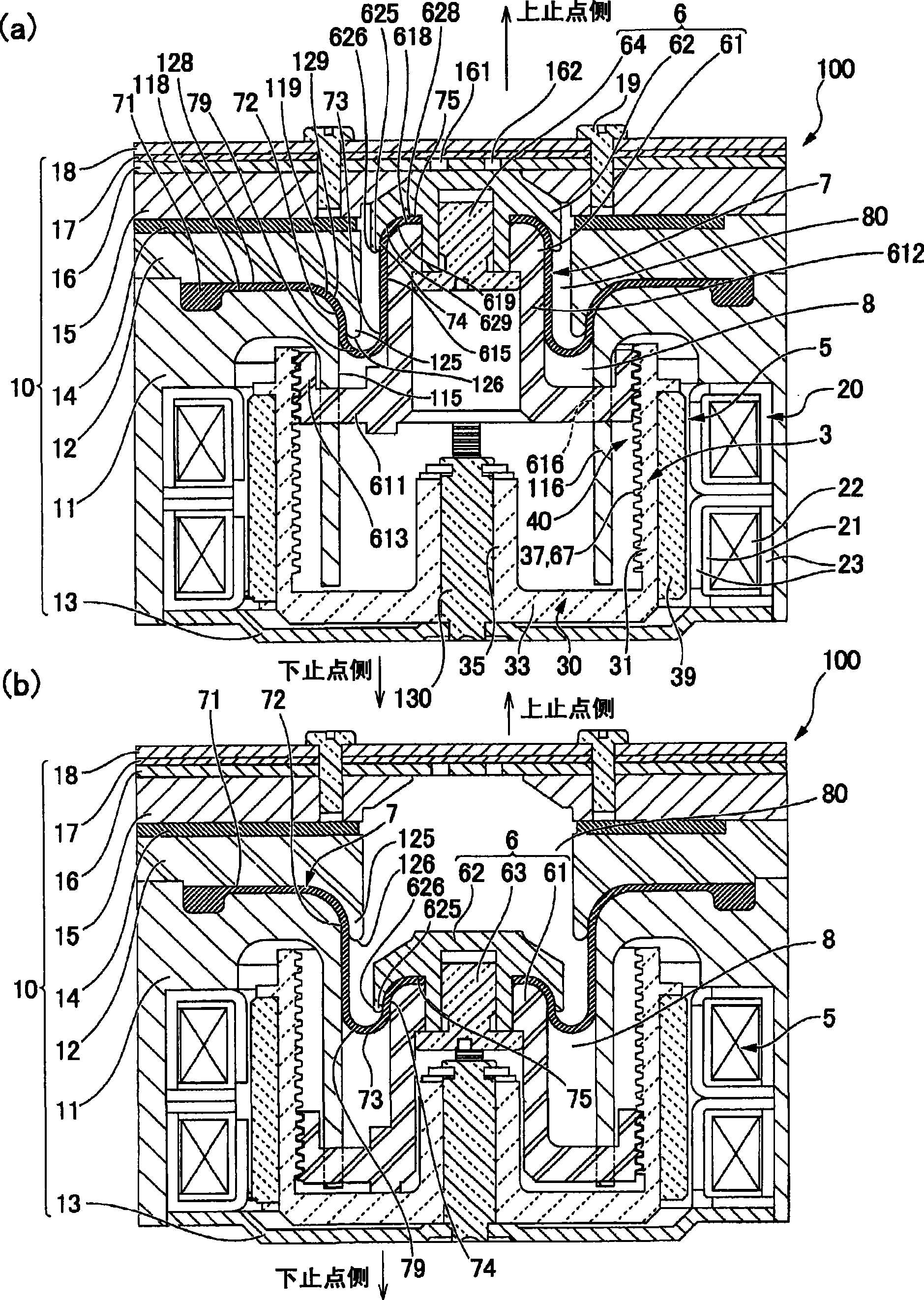

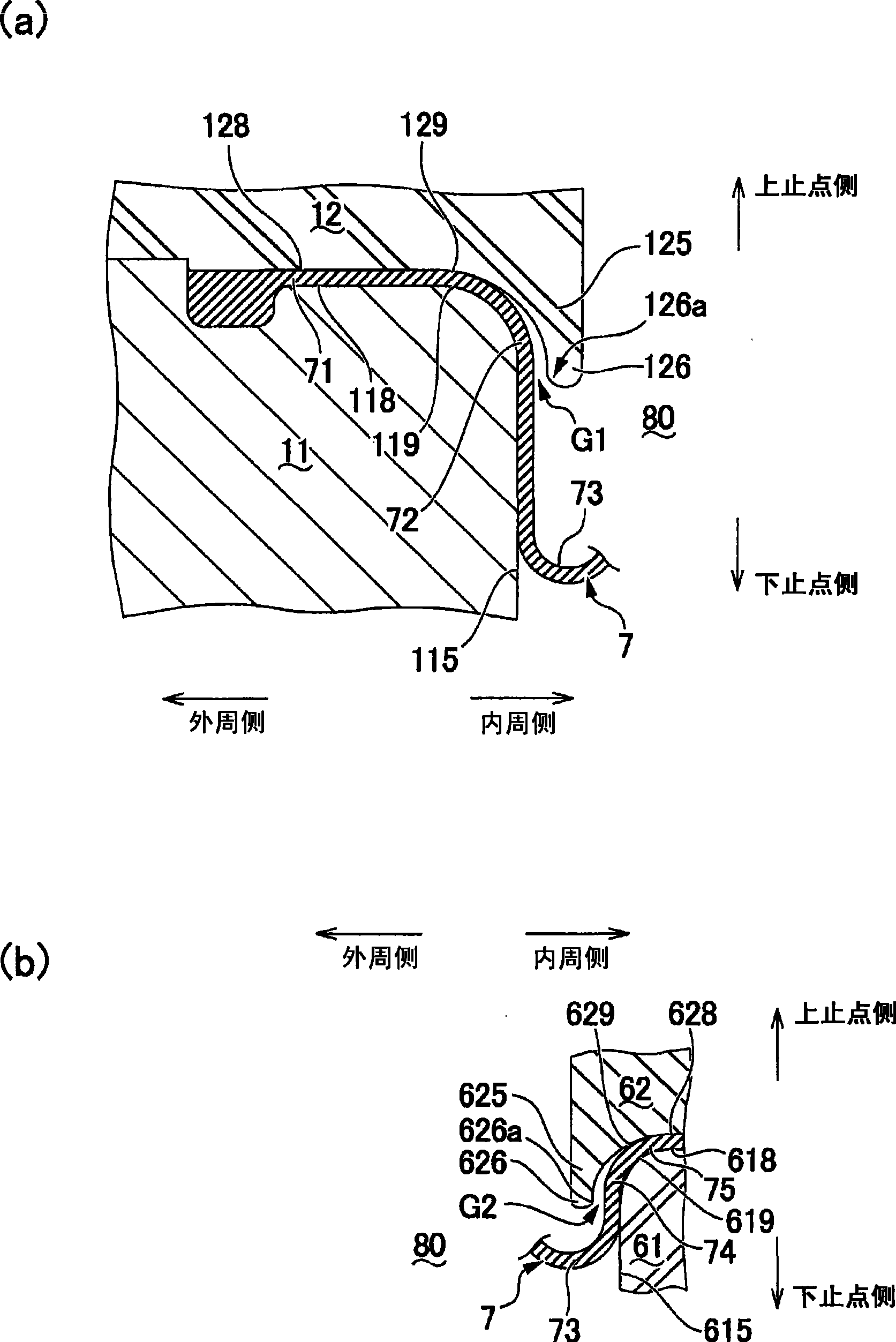

[0060] figure 1 (a), (b) are longitudinal sectional views of the diaphragm pump device to which the present invention is applied, figure 1 (a) shows the state of the piston at the top dead center, figure 1 (b) shows the state where the piston is at the bottom dead center.

[0061] exist figure 1 In (a), the diaphragm pump device 100 (diaphragm cylinder device) of this embodiment is a pump device for sucking or discharging liquid, and has: a cylinder chamber 8 extending in the axial direction in the fixed body 10; The piston 6 inside 8, and the diaphragm 7 on the side of the fixed body 10 and the side of the piston 6 are respectively fixed on the outer peripheral side and the inner peripheral side. The diaphragm 7 divides and forms a chamber 80 for fluid inflow and outflow in the cylinder chamber 8 . In addition, in the diaphragm pump device 100, a driving device 5 for driving the piston 6 along the axial direction of the cylinder chamber 8 i...

Embodiment approach 2

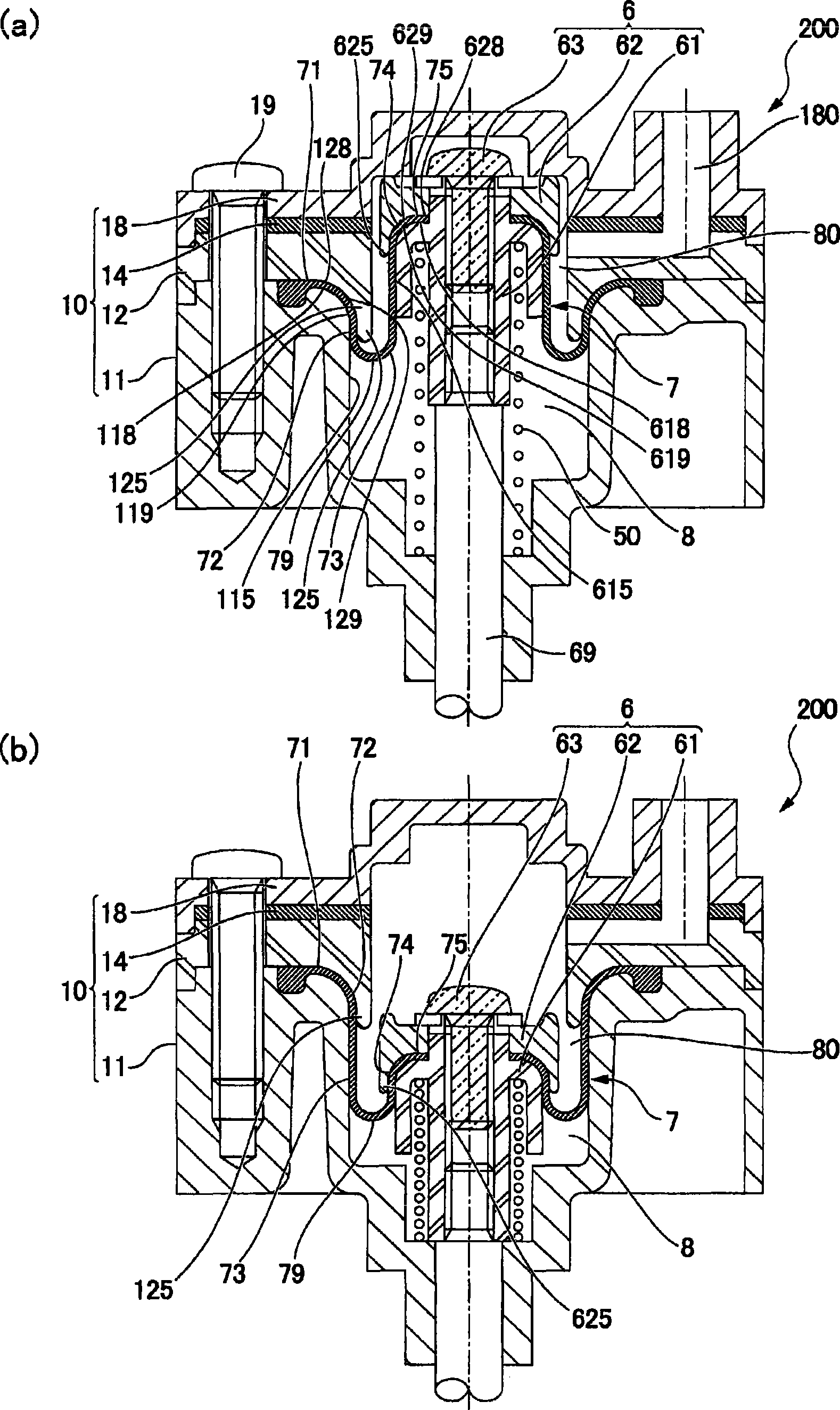

[0094]In Embodiment 1 above, the diaphragm cylinder device to which the present invention is applied is applied to the diaphragm pump device. An example of an actuator that displaces a piston in the axial direction and outputs the displacement to the outside.

[0095] image 3 (a), (b) are longitudinal sectional views of the actuator to which the present invention is applied, image 3 (a) shows the state of the piston at the top dead center, image 3 (b) shows the state where the piston is at the bottom dead center. Figure 4 It is an explanatory diagram schematically showing the operation of the actuator to which the present invention is applied. In the actuator of this embodiment, the configuration as a diaphragm cylinder device is the same as that of Embodiment 1. Therefore, in order to make the corresponding relationship easy to understand, the same reference numerals are assigned to the parts having common functions as much as possible.

[0096] exist image 3 In (a)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com