Numerical control paper stacker

A technology of paper stacking and paper cutting machine, which is applied in the directions of sending objects, stacking receiving device, thin material processing, etc. It can solve the problems of immature technology, inability to realize automatic paper stacking, and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

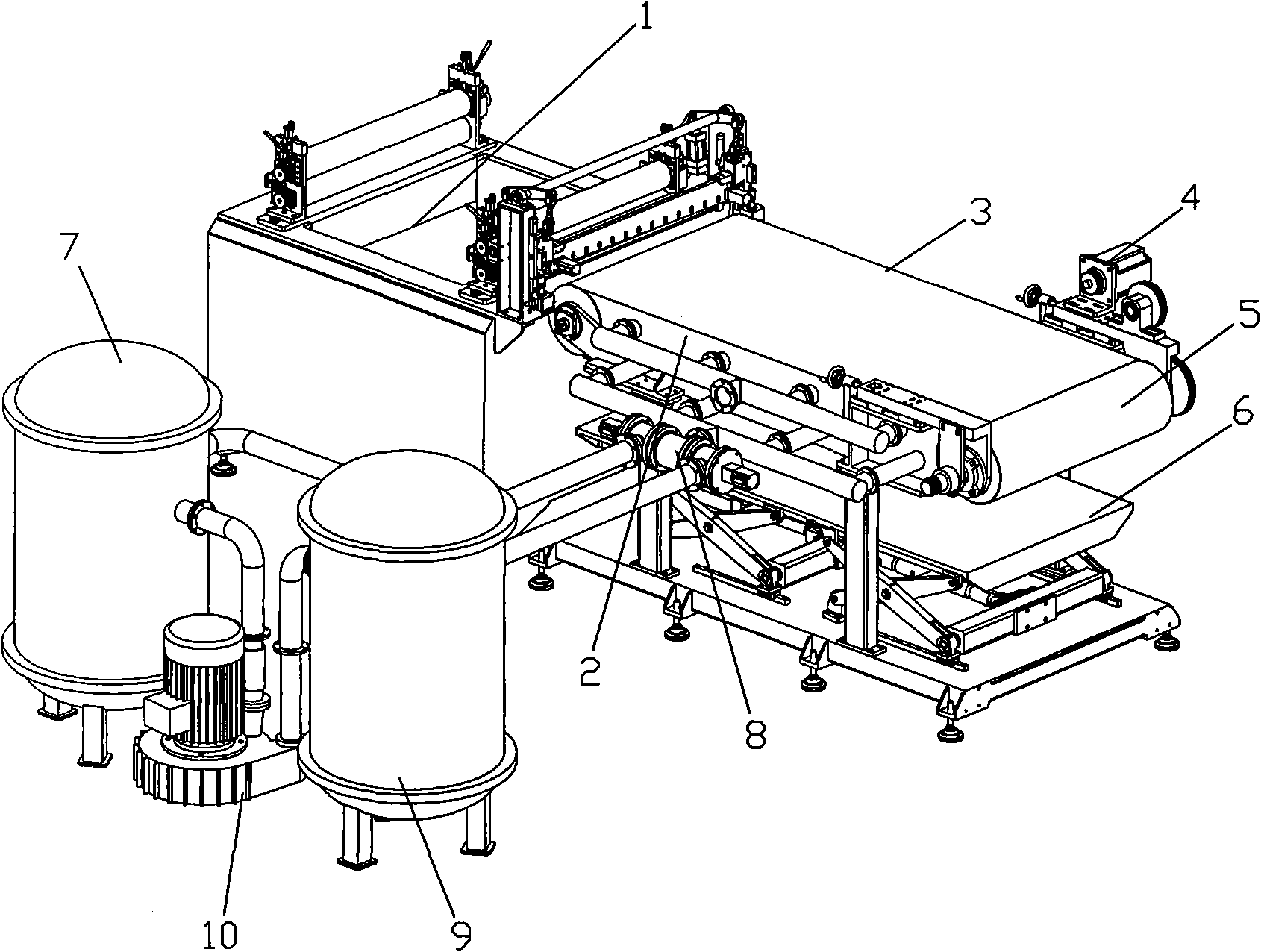

[0011] refer to figure 1 , a numerically controlled paper stacker, comprising a roll paper cutter 1, one side of the roll paper cutter 1 is provided with a breathable belt conveyor, the belt conveyor includes a pallet box 2, two of the pallet box 2 The end is provided with a roller barrel 5, and the roller barrel 5 is provided with a conveying belt 3, and the pallet box 2, the roller barrel 5 and the conveying belt 3 are provided with some air-permeable small holes; the belt conveyor is equipped with a driving device 4 , and the belt conveyor is provided with a lifting platform 6, and the belt conveyor is connected with a positive and negative pressure gas device, and the positive and negative pressure gas device includes a negative pressure gas storage tank 9 and a positive pressure gas storage tank 7, and the negative pressure gas storage tank 9 is connected with the positive pressure gas storage tank 7 with a positive and negative pressure reversing valve 8, the positive an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com