Process for preparing arene selectivity by enhancing methanol aromatizatian and process for preparation of catalyst thereof

An aromatization and selective technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem that the modified HZSM-5 molecular sieve has little effect, and achieve increased yield and improved selection. performance, improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

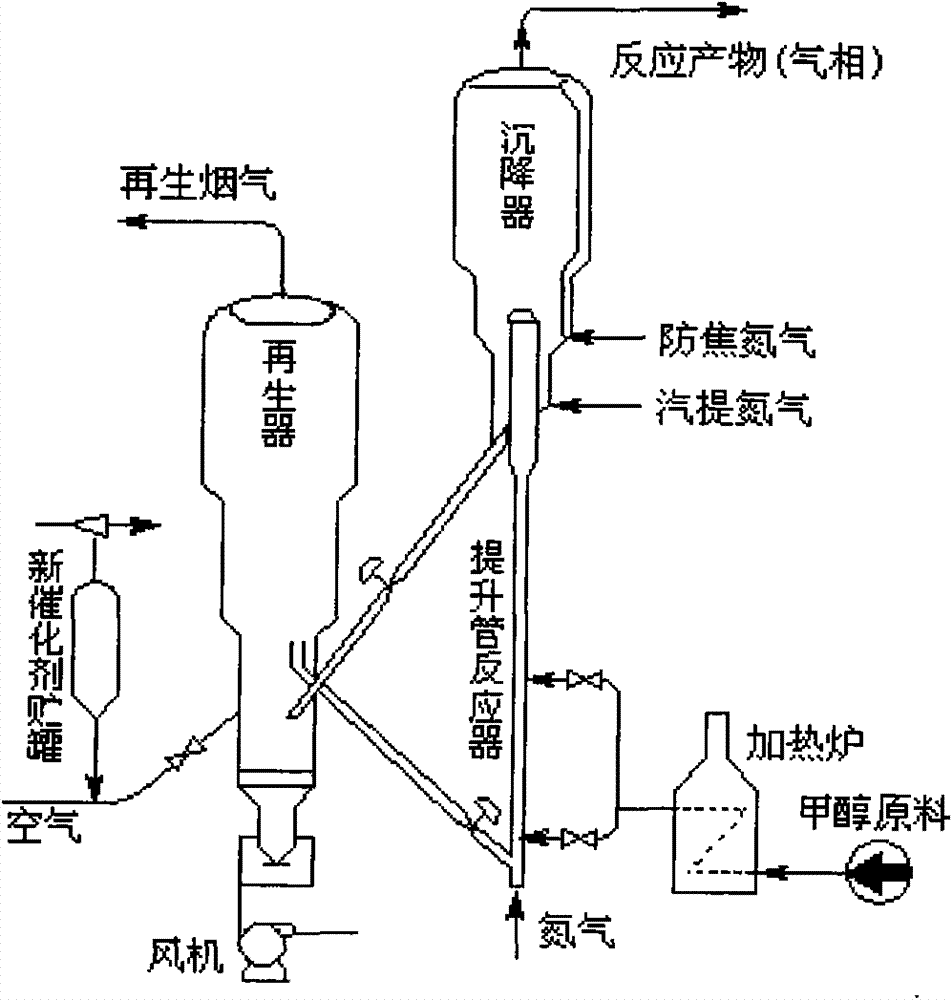

Image

Examples

Embodiment 1

[0012] 1. Catalyst preparation

[0013] (1) Weigh 30 grams of a commercially available powdered HZSM-5 molecular sieve with a Si / Al (atomic ratio) of 38, and bake it at 520° C. for 4 hours to remove volatile components.

[0014] (2) Take 15 grams of the molecular sieve obtained in step (1) in a mortar, add 5 grams of pseudo-boehmite, mix thoroughly, and grind evenly.

[0015] (3) Add 5wt% nitric acid dropwise to the ground material, knead properly, pass through a 100-mesh sieve, press into tablets with a rotary tablet press, put into an oven and dry at 110°C.

[0016] (4) Put the prepared flaky molecular sieve into a high-temperature furnace, firstly raise the temperature to 120°C by step heating method, keep the temperature for 0.5 hours, then raise the temperature to 300°C, keep it for 1 hour, and finally raise the temperature to 520°C, keep it for 4 hours, To remove nitric acid and moisture, etc., then cool down to room temperature naturally, and process it into a block wi...

Embodiment 2

[0042] In step (3), the material after passing through the 100-mesh sub-sieve can also be extruded into a columnar shape with a diameter of 2-3mm by a screw extruder.

[0043] Using copper, zinc, gallium, phosphorus, and silver mixed with various ions, according to the above-mentioned embodiment 1, adopting a fluidized bed method to catalyze the reaction, the yield of the obtained aromatics can reach 55-70wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com